Externally-wrapped steel plate reinforced concrete assembled shear wall and construction method thereof

A technology of reinforced concrete and combined shear walls, which is applied to walls, buildings, building components, etc. It can solve the problems that it is difficult to take into account the welding workload and the tension of steel plate walls, and achieve high construction efficiency, cost savings, and improved brittle failure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

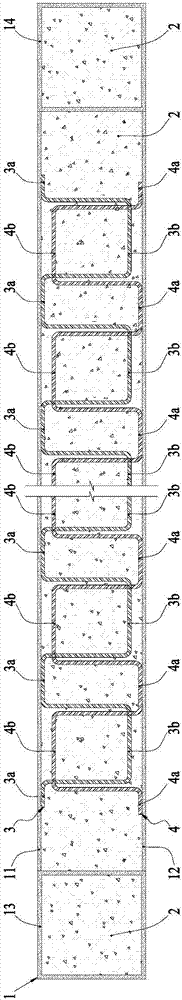

[0049] Such as figure 1 As shown, the first embodiment of the present invention is based on the above-mentioned inventive concept, and adopts the following specific schemes for the first stirrup 3 and the second stirrup 4:

[0050] In the first embodiment, the first stirrup 3 and the second stirrup 4 are formed by bending a steel bar; and the welding section 3a of the first stirrup 3 and the welding section 4a of the second stirrup 4 are both Linear type, the raised section 3b of the first stirrup 3 and the raised section 4b of the second stirrup 4 are both U-shaped.

Embodiment 2

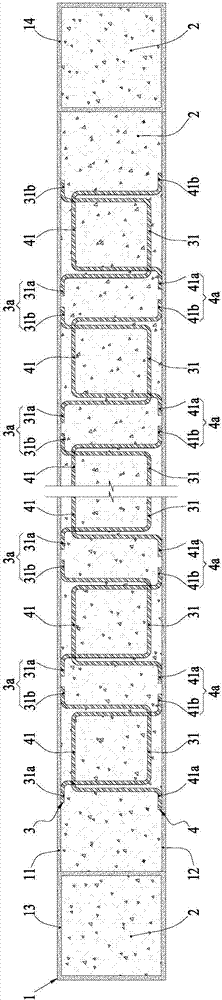

[0052] Such as figure 2 As shown, the second embodiment of the present invention is based on the above-mentioned inventive concept, and adopts the following specific schemes for the first stirrup 3 and the second stirrup 4:

[0053] In the second embodiment, the welded section 3a of the first stirrup 3 and the welded section 4a of the second stirrup 4 are linear, and the raised section 3b of the first stirrup 3 and the raised section of the second stirrup 4 4b are U-shaped; and, the first stirrup 3 and the second stirrup 4 are composed of a plurality of stirrup units and are arranged at intervals along the horizontal extension direction of the outer steel plate wall 1, each of the first stirrup 3 Each stirrup unit 41 of the section stirrup unit 31 and the second stirrup 4 is formed by bending a steel bar, and has a raised section and left welding sections and right welding sections respectively located at the two ends of the raised section. Welding section; the first stirrup...

Embodiment 3

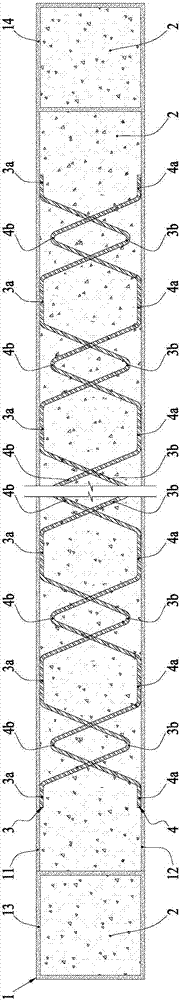

[0055] Such as image 3 As shown, the third embodiment of the present invention is based on the above-mentioned inventive concept, and adopts the following specific schemes for the first stirrup 3 and the second stirrup 4:

[0056] In the third embodiment, the first stirrup 3 and the second stirrup 4 are bent from a steel bar; and the welding section 3a of the first stirrup 3 and the welding section 4a of the second stirrup 4 are both Straight line, the protruding section 3b of the first stirrup 3 and the protruding section 4b of the second stirrup 4 are both V-shaped.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com