A kind of steel plate shear wall with two-way arrangement of multi-layer oblique grooves

A steel plate shear wall and multi-layer steel plate technology, applied to walls, buildings, building components, etc., can solve problems such as easy cracking, inability to accurately judge yield load and energy dissipation capacity, and safety concerns of buckling-resistant steel plate shear walls. To achieve the effect of avoiding compression buckling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

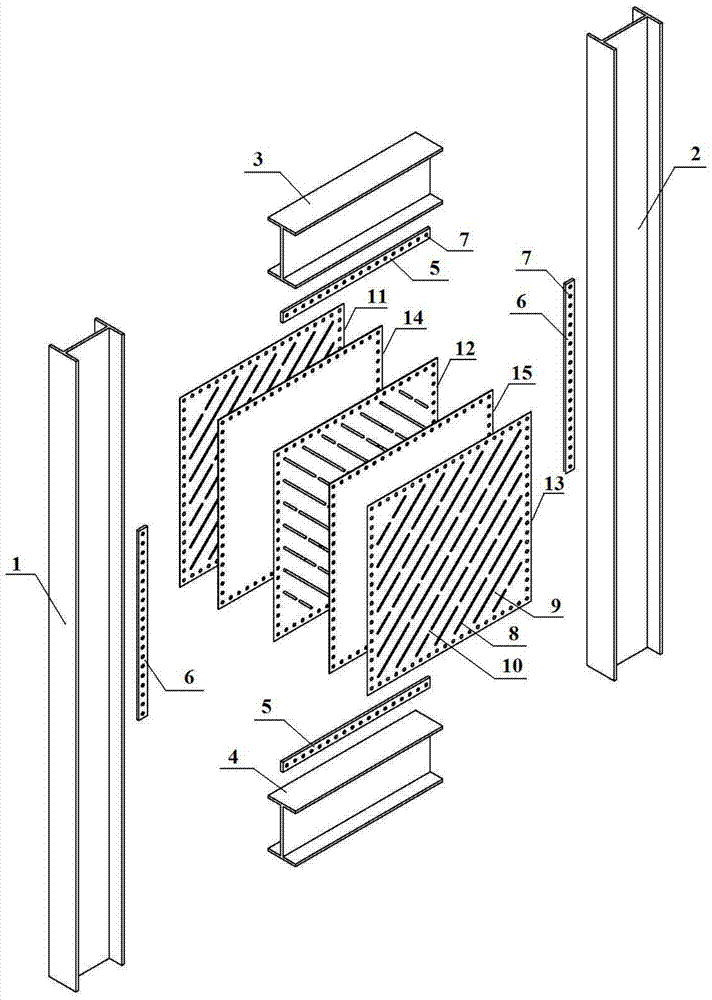

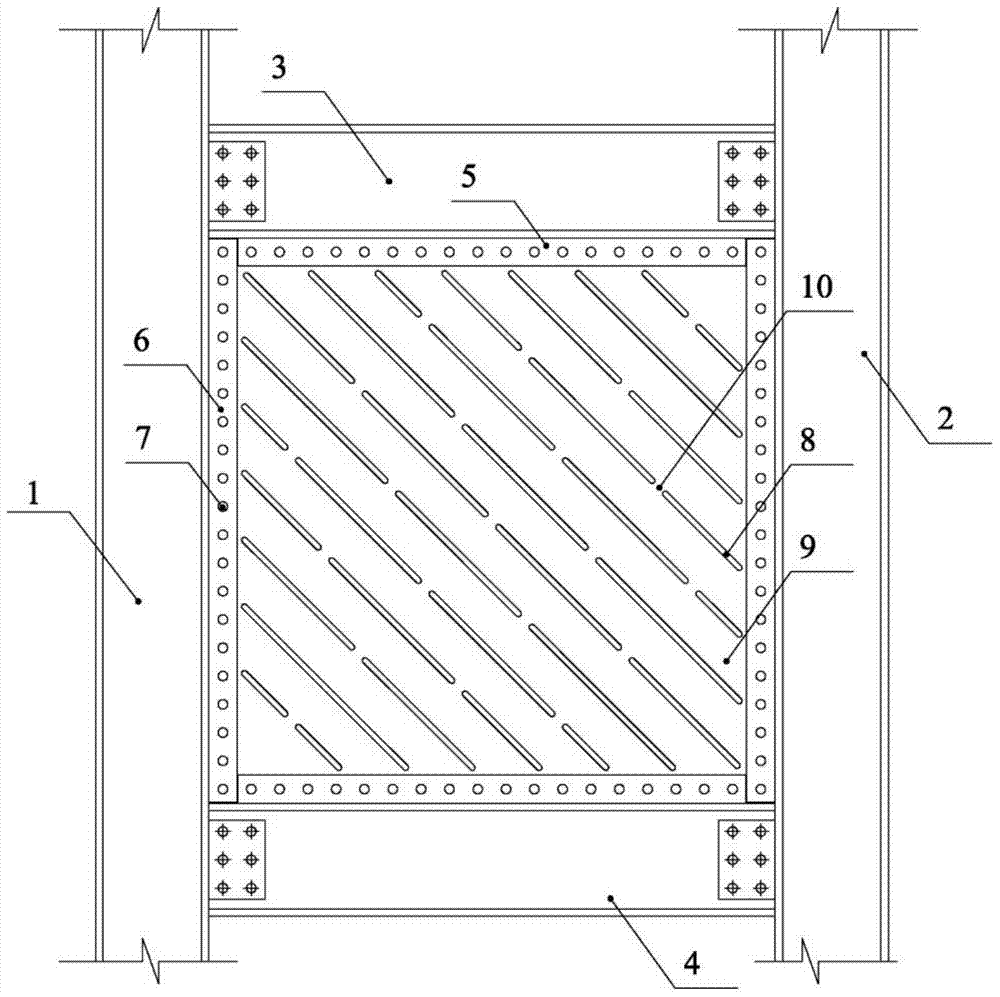

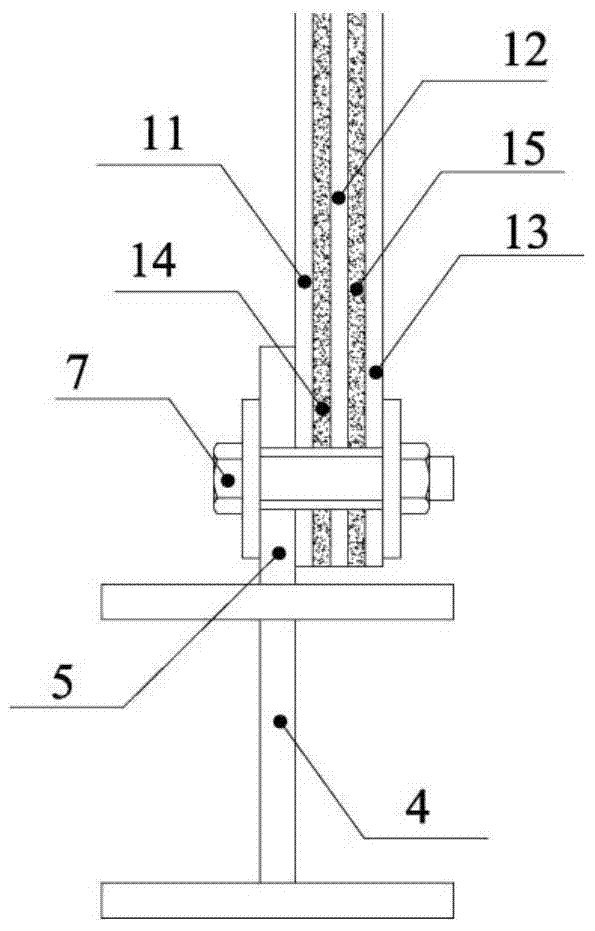

[0019] The present invention is described in detail below in conjunction with accompanying drawing (taking three-layer steel plate shear wall as example).

[0020] Depend on figure 1 , figure 2 and image 3 It can be seen that a multi-layer obliquely slotted bidirectionally arranged steel plate shear wall includes multi-layer obliquely slotted steel plates, edge frames and polytetrafluoroethylene plates arranged between different steel plates. Wherein, the multi-layer obliquely grooved steel plate includes a first layer steel plate 11 , a second layer steel plate 12 and a third layer steel plate 13 , and the second layer steel plate 12 is located between the first layer steel plate 11 and the third layer steel plate 13 . The steel plate shear wall 11 of the first layer and the steel plate shear wall 13 of the third layer have the same thickness, and the sum of their thicknesses is equal to the thickness of the steel plate shear wall 12 of the second layer. The directions o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com