Planar-bending corrugated sheet steel beam and making technology thereof

A manufacturing process and corrugated plate technology, applied in the field of corrugated plate steel beams and manufacturing processes, can solve problems such as inability to meet special structures, and achieve the effects of beautiful overall structure, low cost and convenient production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

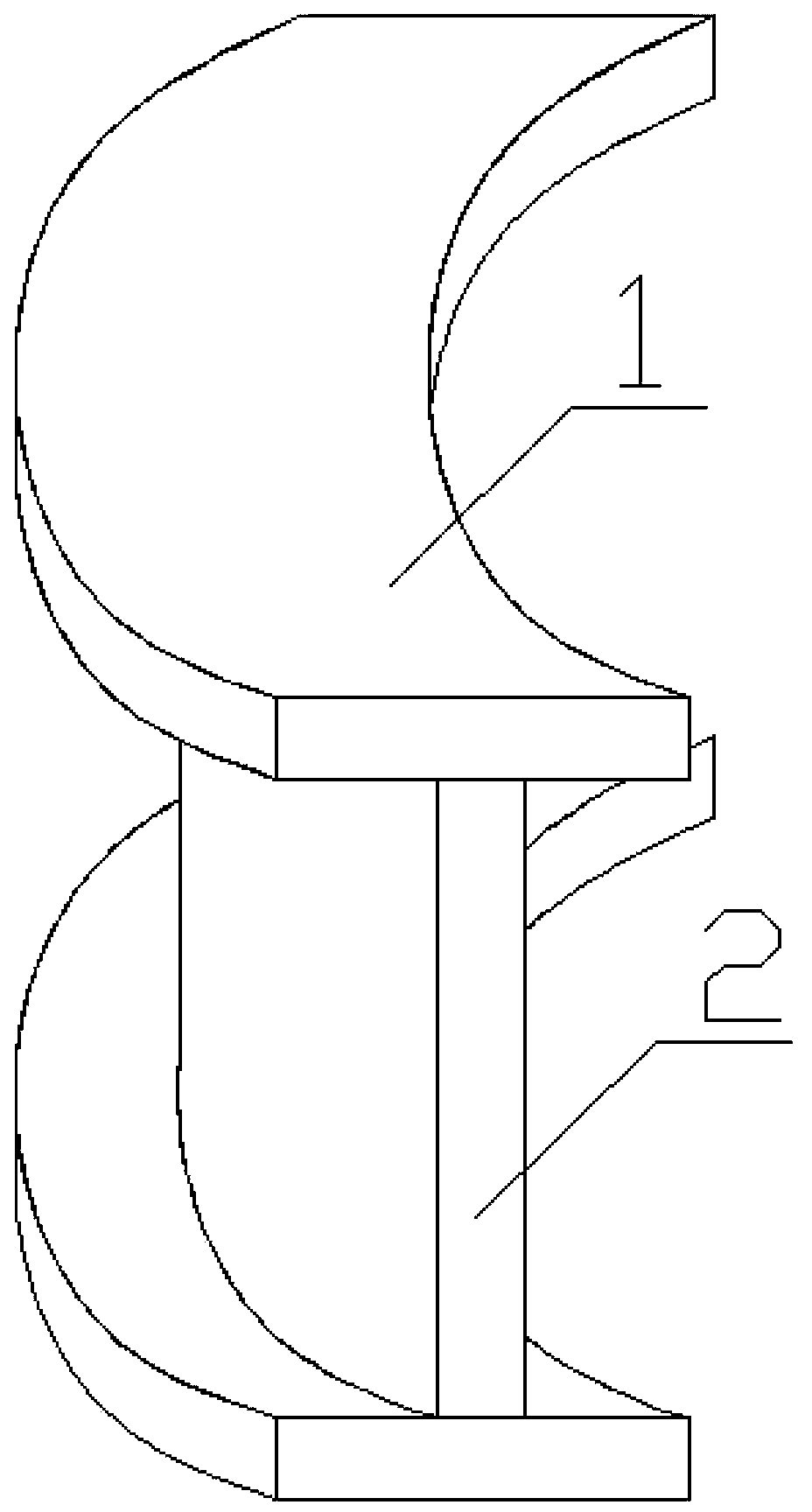

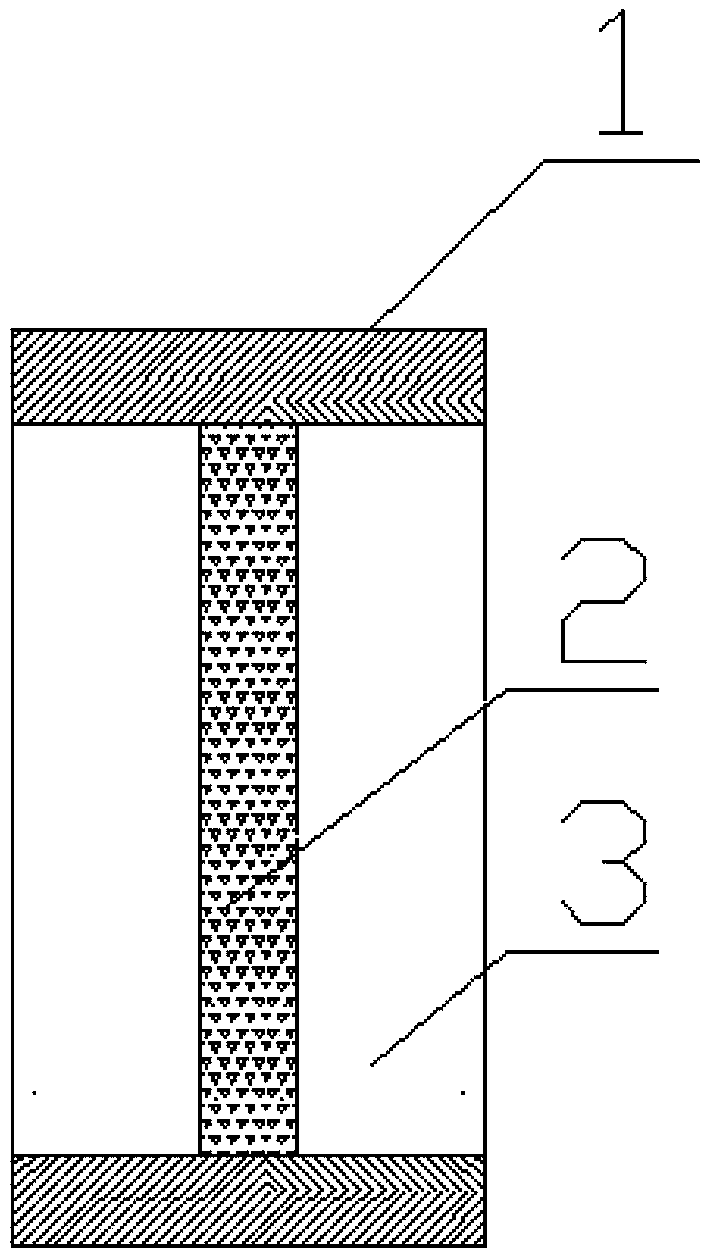

[0020] A corrugated plate steel beam bent in the plane direction, including a flange plate 1, a corrugated steel plate 2, and a stiffening plate 3, the flange plate 1 is located at the top or bottom of the corrugated steel plate 2; The top view of the flange plate 1 after horizontal sectioning is arc-shaped, and the arc and arc direction of the flange plate 1 and the corrugated steel plate 2 are consistent; the corrugated steel plate 2 and the flange plate 1 are welded and connected.

[0021] The stiffening steel plate 3 is welded to the corrugated steel plate 2 or / and the flange plate 1 .

[0022] The corrugated steel plate 2 has a convex or concave arc shape in the horizontal direction.

[0023] The number of stiffening steel plates 3 is more than two, and the number of corrugated steel plates 2 is more than one.

[0024] The stiffened steel plate 3 adopts a corrugated plate or a T-shaped plate, and the planes of the stiffened steel plate are not completely parallel.

Embodiment 2

[0026] The manufacturing process of the corrugated plate steel girder bent in the plane direction includes the following steps:

[0027] a. Typesetting of steel plate raw materials;

[0028] b. CNC cutting and blanking;

[0029] c. The corrugated steel plate 2 is rolled and formed;

[0030] d. Secondary forming of the corrugated steel plate 2 in the horizontal direction;

[0031] e. The corrugated steel plate 2 is assembled with the flange plate 1;

[0032] f. The flange plate 1 and the stiffening steel plate 3 are welded to the corrugated steel plate 2 respectively.

[0033] The method of CNC cutting and blanking is CNC zigzag cutting; the corrugated steel plate 2 adopts the wave-band step-by-step forming method.

[0034] The amplitude of the step-shaping is equal to the unfolded length of a unit wave.

[0035] The welding sequence of the flange plate 1 and the corrugated steel plate 2 is from both sides to the middle. The welding process takes the wave length as the wel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com