Heat pump water heater with liquid homogenization device and liquid homogenization method

A technology of heat pump water heater and liquid homogenizing device, which is applied in refrigerators, refrigeration and liquefaction, lighting and heating equipment, etc., can solve the problem that the liquid separator cannot evenly distribute the refrigerant gas-liquid mixture, and the evaporator processing consistency is not good. , Uneven air flow through the heat exchanger, etc., to reduce the exhaust temperature, improve the uniformity of liquid separation, and increase the heating capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

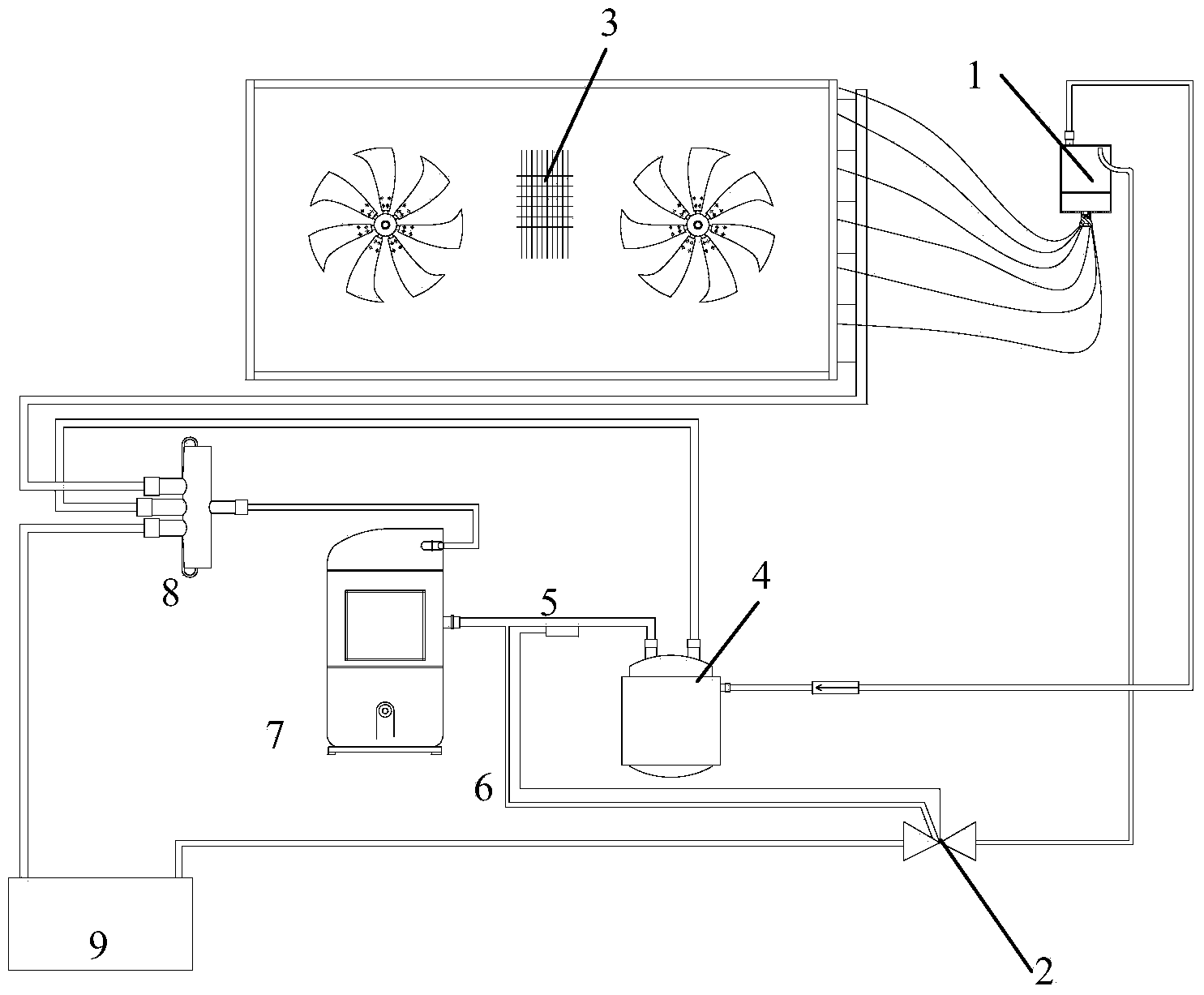

[0037] Such as figure 1 As shown in the figure, a heat pump water heater with a homogenizing device includes a separating homogenizer 1, an expansion valve 2, a gas-liquid separator 4, a compressor 7, a water-cooled condenser 9, a four-way valve 8 and a finned evaporator 3. The expansion valve 2 is connected with the separation homogenizer 1 through a liquid inlet pipe 11, and the liquid inlet pipe 11 extends into the top of the cylinder body 10 of the separation homogenizer 1, and sprays liquid from the top of the cylinder body 10.

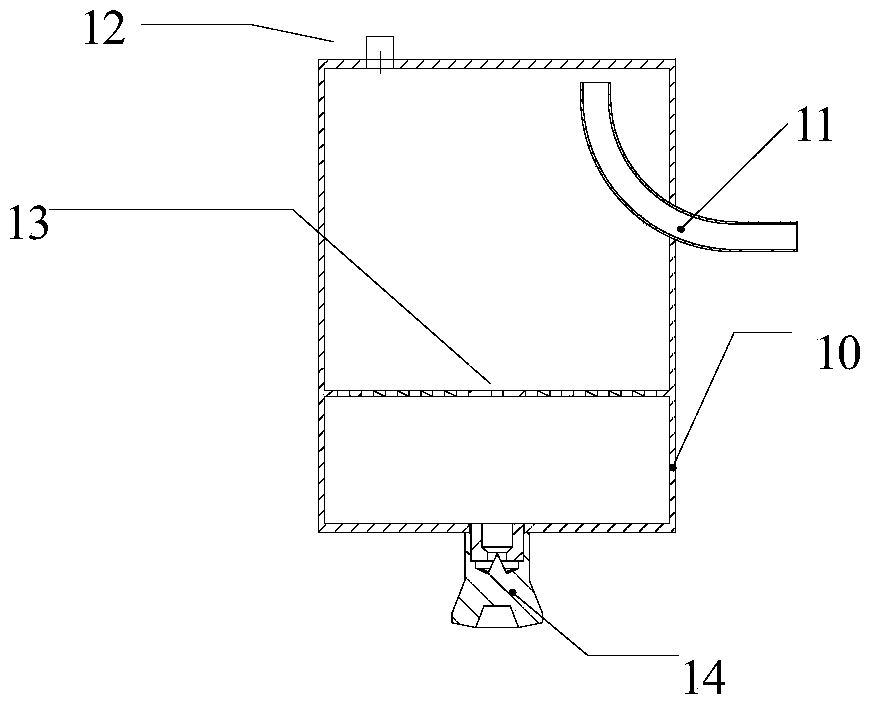

[0038] Such as figure 2 As shown, the separating liquid homogenizer 1 includes a cylinder body 10, an air outlet 12 at the top of the cylinder body and a liquid homogenizer 14 at the bottom of the cylinder body. A partition 13 is embedded below the liquid inlet pipe 11 in the cylinder body. The plate 13 i...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap