High-pressure pilot-operated type pneumatic electromagnetic-valve valve element displacement measurement device and method

A technology of pneumatic solenoid valve and spool displacement, which is applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems that the displacement of the main spool cannot be detected by the non-sealed structure, the measurement of the displacement of the spool is difficult, and the structure is complicated, etc. And the method is stable and reliable, the cost is low, and the effect of the device structure is simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings.

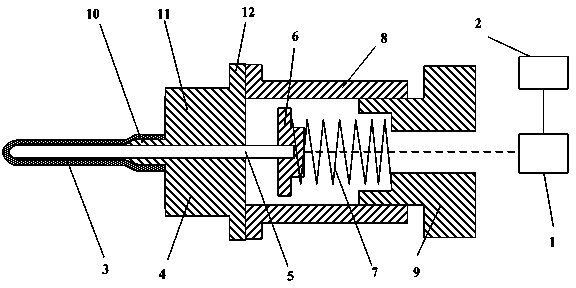

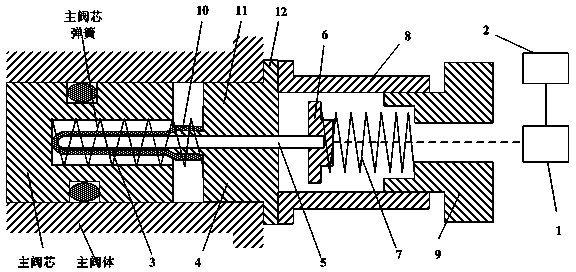

[0022] combine figure 1 , The high-pressure pilot-operated pneumatic solenoid valve spool displacement measuring device of the present invention includes a spool displacement transmission device, a laser displacement sensor 1, and a data acquisition instrument 2. The spool displacement transmission device includes a rubber tube 3 , a sealing cover 4 , a guide rod 5 , a measuring baffle 6 , a compression spring 7 , a fixing sleeve 8 and an adjusting nut 9 .

[0023] The specific installation process of the high-pressure pilot pneumatic solenoid valve spool displacement measuring device: the rubber tube 3 is glued and fixed on the first cylinder 10 of the sealing cover 4, and the sealing cover 4 is connected with the valve body of the measured valve with threads, and the The guide rod 5 is inserted into the rubber tube 3 through the central through hole of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com