Universal type online collecting mechanism for in-service flanges

A flange sealing and collecting mechanism technology, applied in flange connection, passing components, mechanical equipment, etc., can solve the problems of inconvenient installation and construction, clogging of heavy liquid or tar, affecting the performance of the main seal, etc., to achieve simple and easy installation. Acquiring, Versatile Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to make the technical means, creative features, objectives and effects achieved by the present invention easy to understand, the present invention will be further elaborated below.

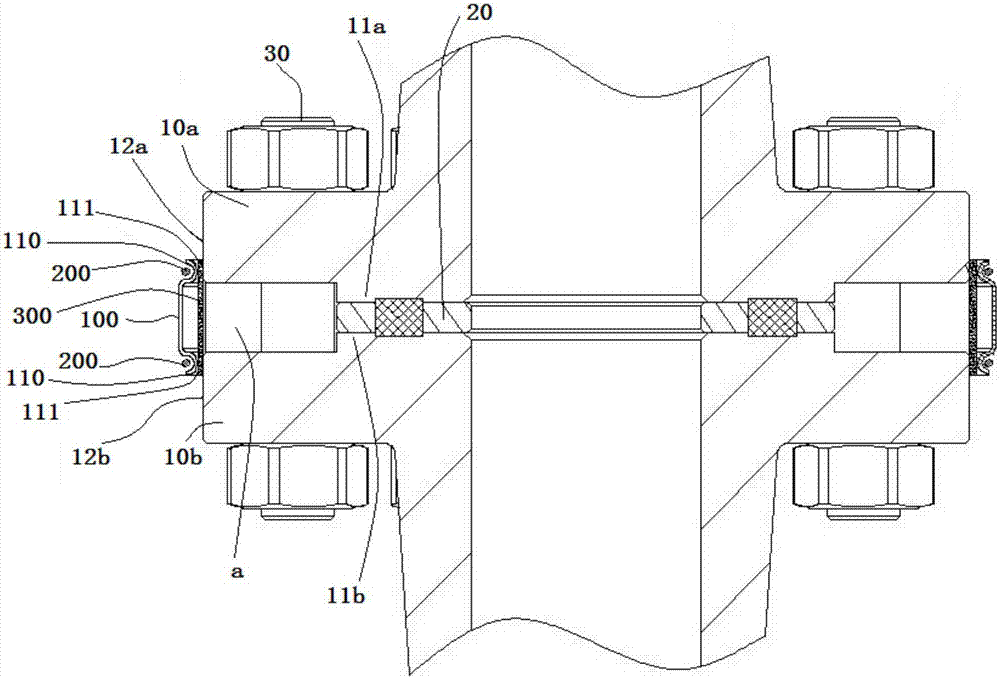

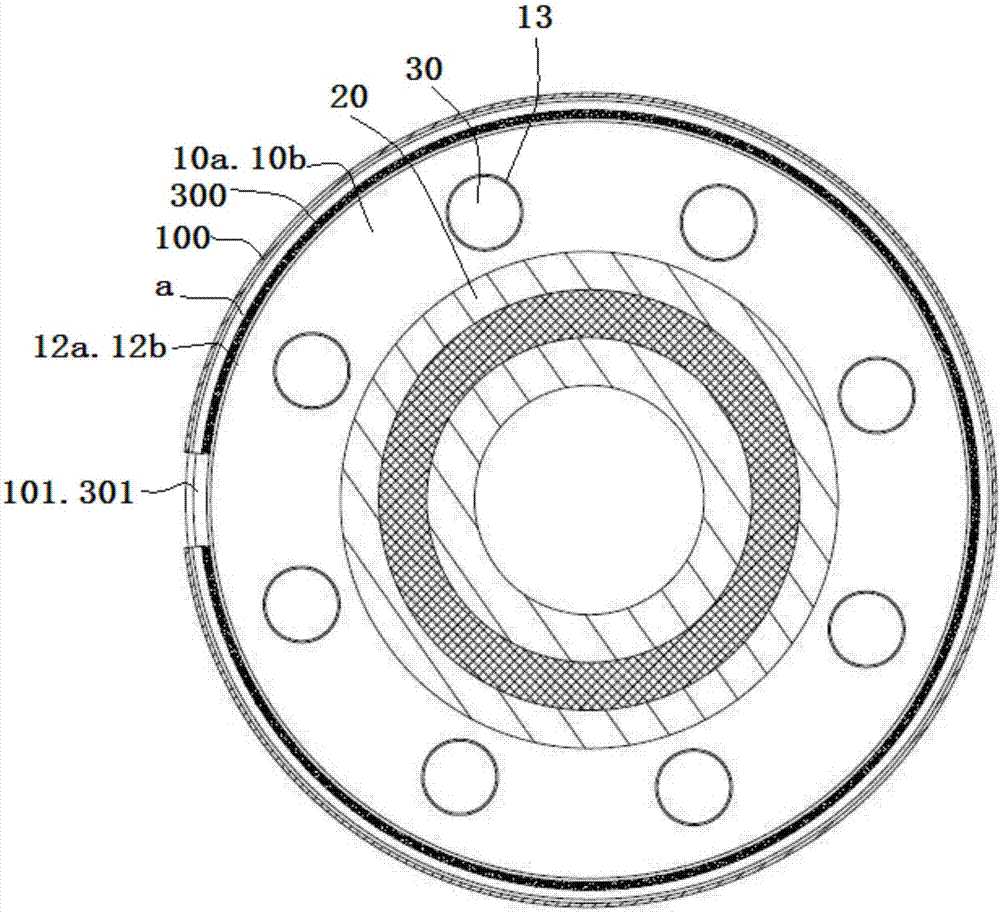

[0034] see Figure 2 to Figure 5 As shown, a common in-service flange seal online collection mechanism includes a C-shaped belt 100 and at least one annular fastening belt 300 . The present invention is applicable to the working condition of flange sealing. When the two flanges 10a, 10b cooperate with each other to seal, and the two flanges 10a, 10b are fixed by bolts 30, the sealing end faces 11a, When 11b compresses the annular gasket 20, the present invention can be used for online collection and leak detection.

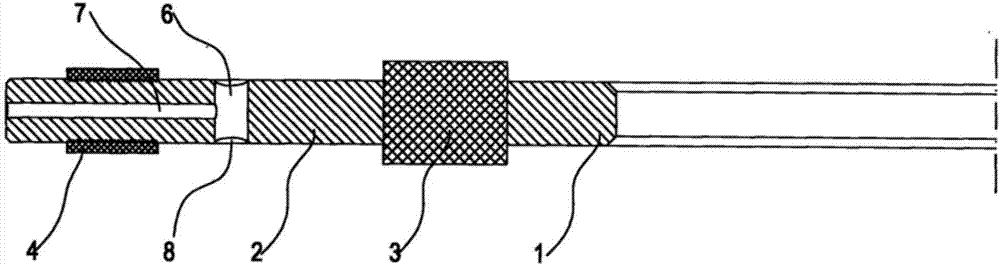

[0035] The C-shaped belt 100 has a notch 101, and the C-shaped belt 100 in this embodiment is made of a steel belt, which is easy to process and low in cost. The inner surfaces of the two axial ends of the C-shaped belt 100 respectively form an inner sealing surface ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com