Quick ferrographic analysis method based on digital video

A digital video, ferrography analysis technology, applied in particle size analysis, material analysis, particle and sedimentation analysis, etc., can solve the problems of fuzzy equivalent features, analytical ferrography without analysis ability, only providing static images, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0063] The content of the present invention will be further described below in conjunction with the accompanying drawings.

[0064] A fast ferrographic analysis method based on digital video, comprising the following steps:

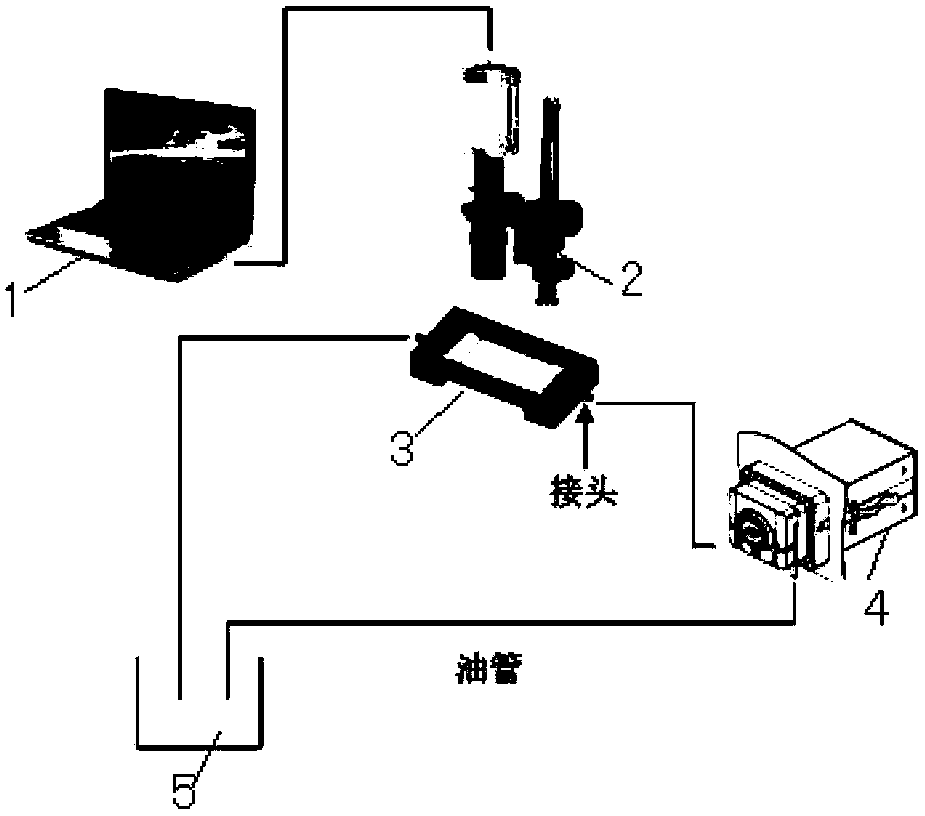

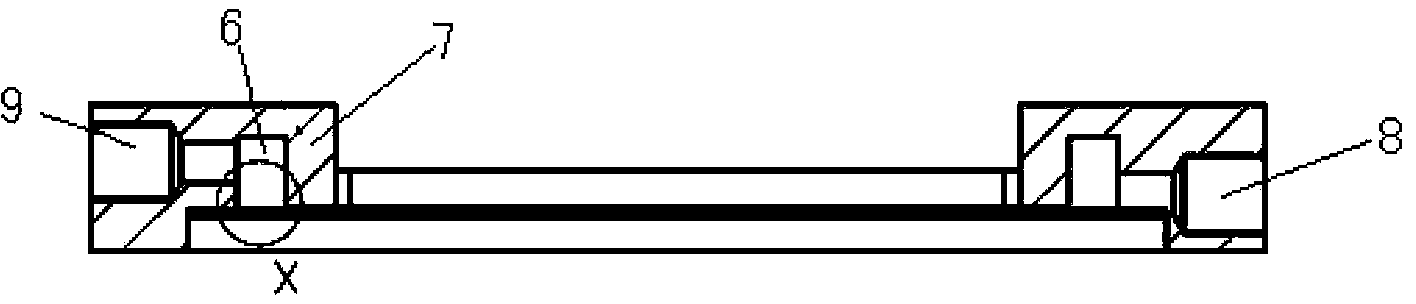

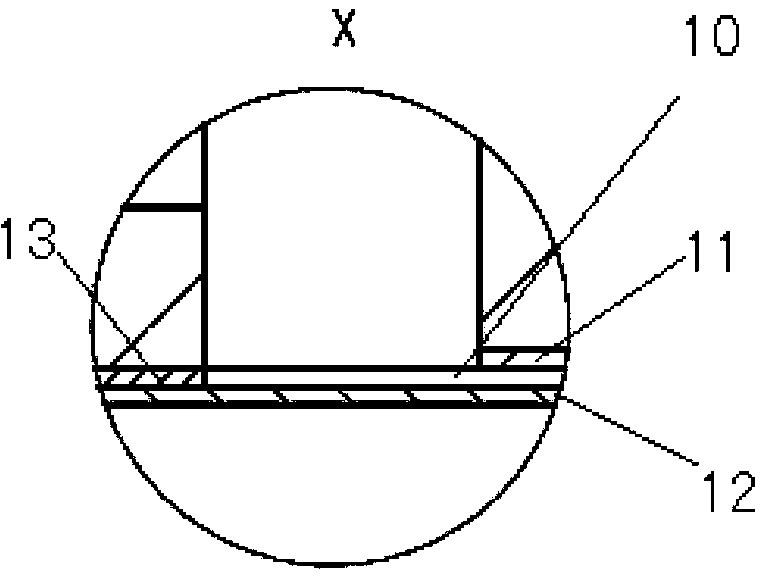

[0065] refer to figure 1 and Figure 5 , step 1, connect the micro-channel 3 and the digital micropump 4 through the oil inlet and outlet of the micro-channel 3 frame with oil pipes and pipe joints, and form an oil circuit with the lubricating oil sample 5 to be tested, the micro-channel 3 is placed directly under the objective lens of the ferrography microscope 2, and the ferrography microscope 2 is connected to the computer 1 through the USB cable of the digital imaging system; the digital micropump 4 delivers the oil to the micro flow channel 3; The abrasive grain image is acquired at the focal length; the computer 1 software control system is turned on, and the abrasive grain image is displayed on the software interface; the rotational speed of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com