Laser measuring machine of cylinder cover valve collet

A laser measurement and door lock technology, applied in the direction of optical testing flaws/defects, etc., can solve problems such as difficult to guarantee error detection rate and high misjudgment rate, and achieve the effect of compact structure, high accuracy and reliable action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below the present invention will be further described in conjunction with the embodiment in the accompanying drawing:

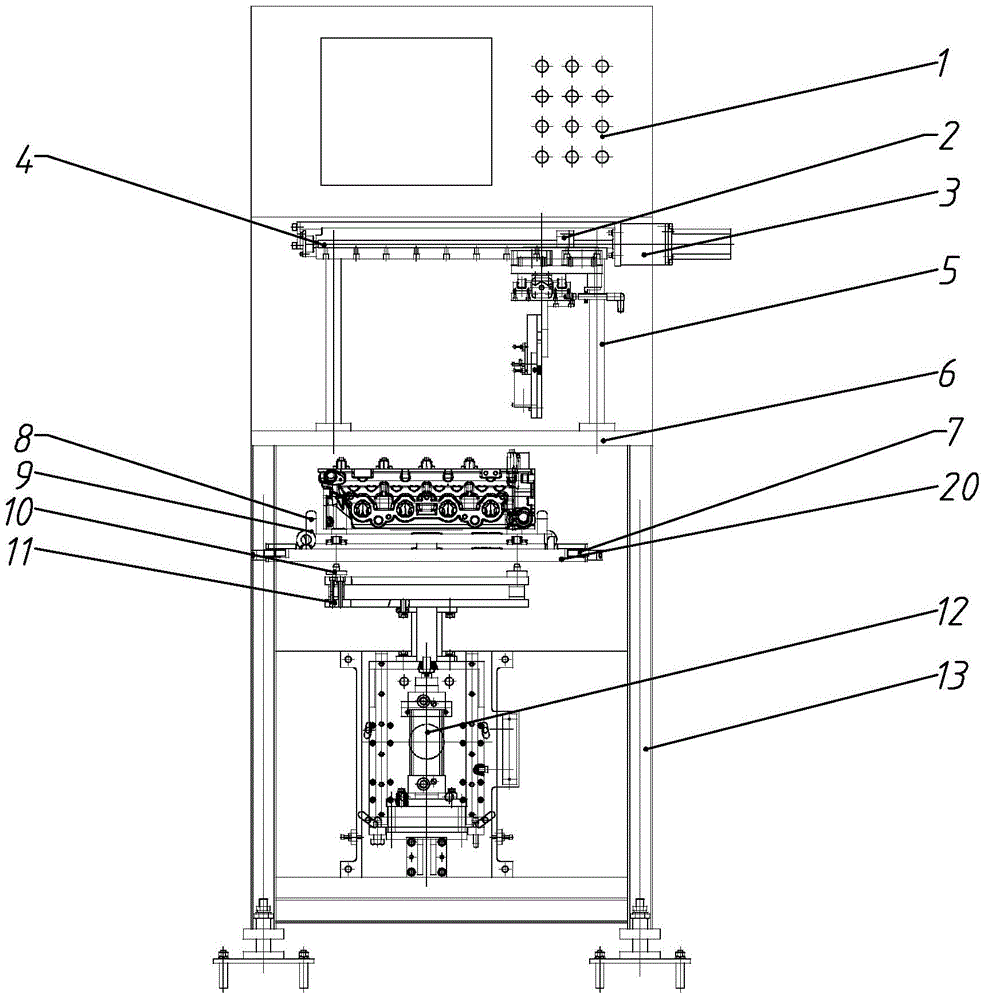

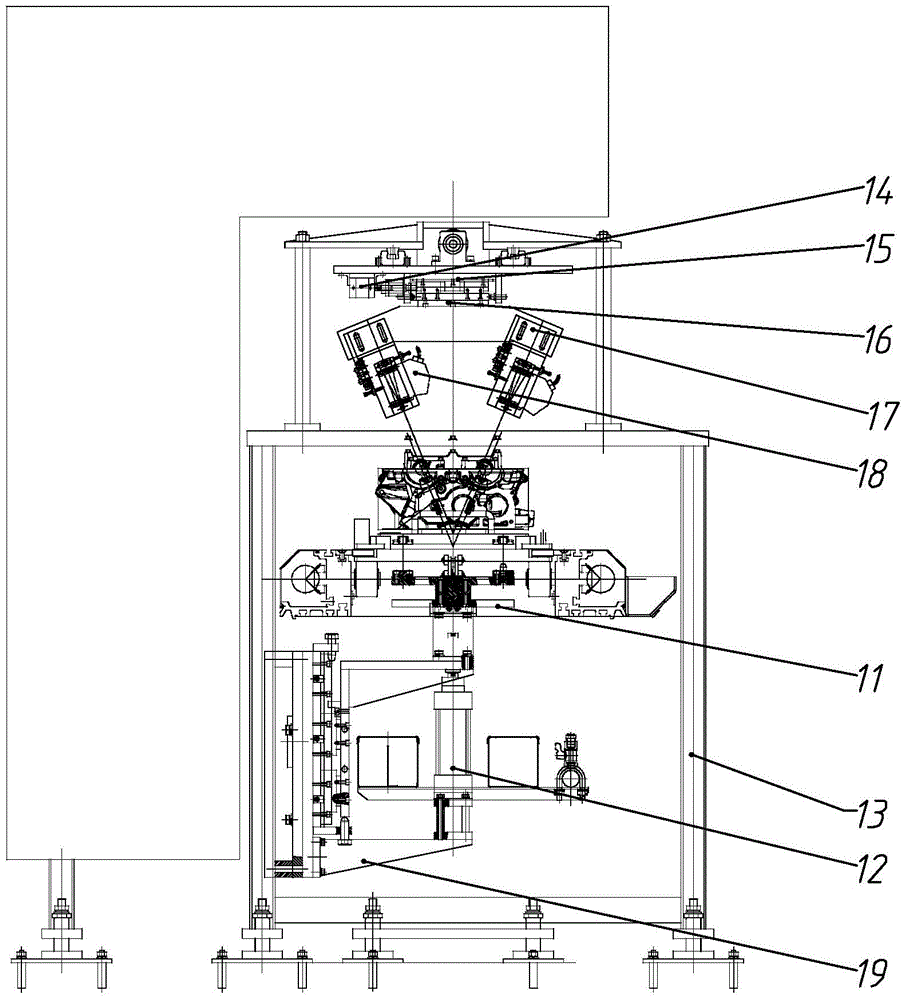

[0016] like Figure 1~2 As shown, the present invention mainly includes a frame 13, the top of the frame 13 is fixed with an operation box 1, and the bottom of the operation box 1 is provided with a measurement platform 6. The screw mandrel support 5 is fixed on the measurement platform 6, and the screw mandrel 4 is installed on the screw mandrel support 5. One end of the screw mandrel 4 is connected to the servo motor 3 that drives the screw mandrel 4 to rotate.

[0017] The lower end of the moving pallet 2 is connected to the horizontal micro-motion mechanism, and the lower end of the horizontal micro-motion mechanism is respectively connected to the laser head 17 on the exhaust side and the laser head 18 on the intake side. The laser head 17 on the exhaust side and the laser head 18 on the intake side Left and right symmetrical settings.

[0018]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com