Three-layer paper model building method based on surface roughness

A surface roughness and model modeling technology, which is applied in special data processing applications, instruments, electrical digital data processing, etc., can solve problems such as poor model effects, and achieve the effect of improving real-time effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

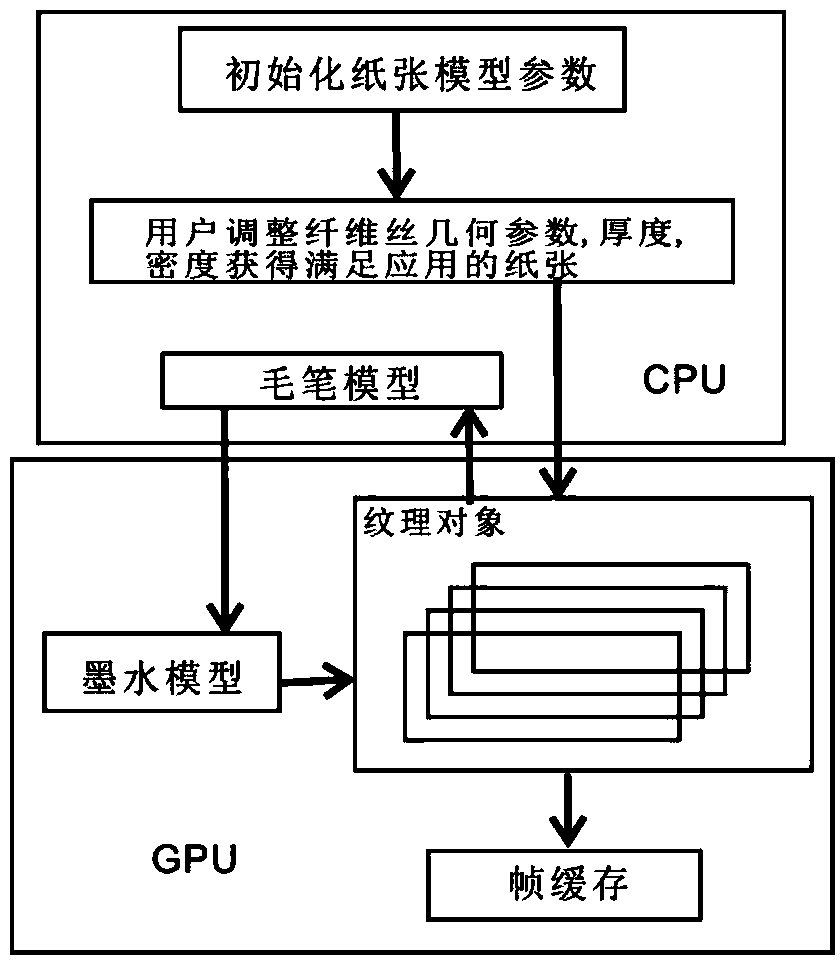

[0029] refer to Figure 1-2 . The three-layer paper model modeling method based on surface roughness of the present invention specifically comprises the following steps:

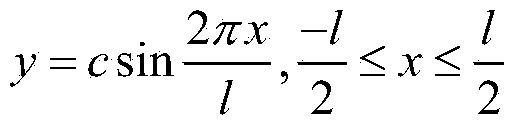

[0030] The influence of the surface roughness of the paper on the writing effect can be divided into two cases according to the amount of ink contained in the writing brush during writing. In the first case, when the amount of ink in the writing brush is rich, the rough surface of the paper diffuses freely from the center of the writing track to the surroundings, and because the fibers contained in the rough surface of the paper are thick, the capillary fiber channels are also spacious, and the entire diffusion The density of the toner contained in the ink is almost unchanged during the process; in the second case, when the amount of ink in the writing brush is low, only the raised part of the paper surface can receive the ink from the brush, while the concave area is unable to contact with the brush conta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com