Universal ground lead for 110 kilovolt overhead line strain tower

A technology for overhead lines and tension towers, applied in the directions of overhead lines/cable equipment, wire-wound connectors, connections, etc., can solve the problems of inconvenient installation and removal of grounding wires, inconvenient manipulation, and difficulty in holding the wire 300, so as to shorten the The effect of power failure maintenance or emergency repair time, labor intensity reduction, and reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

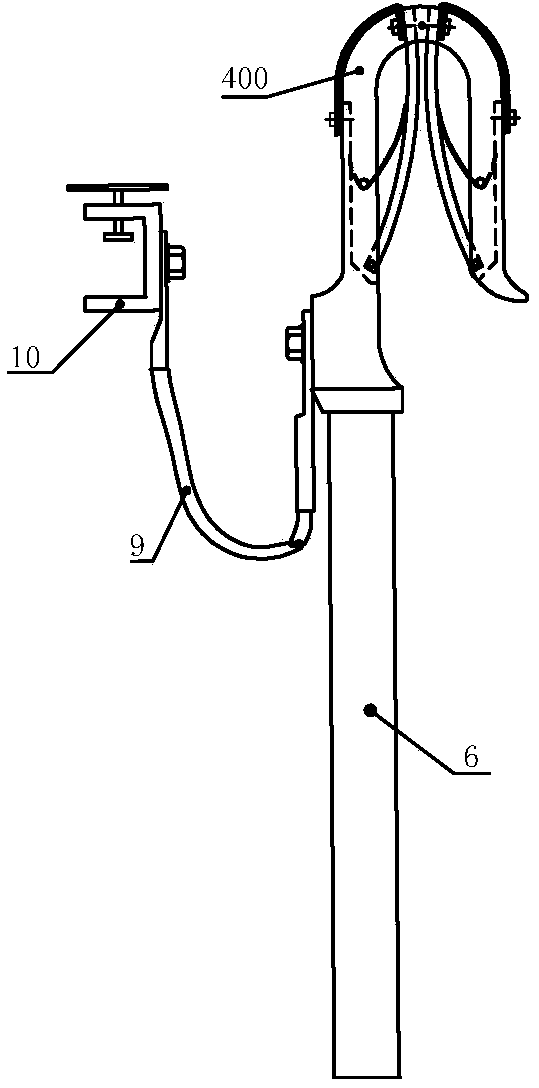

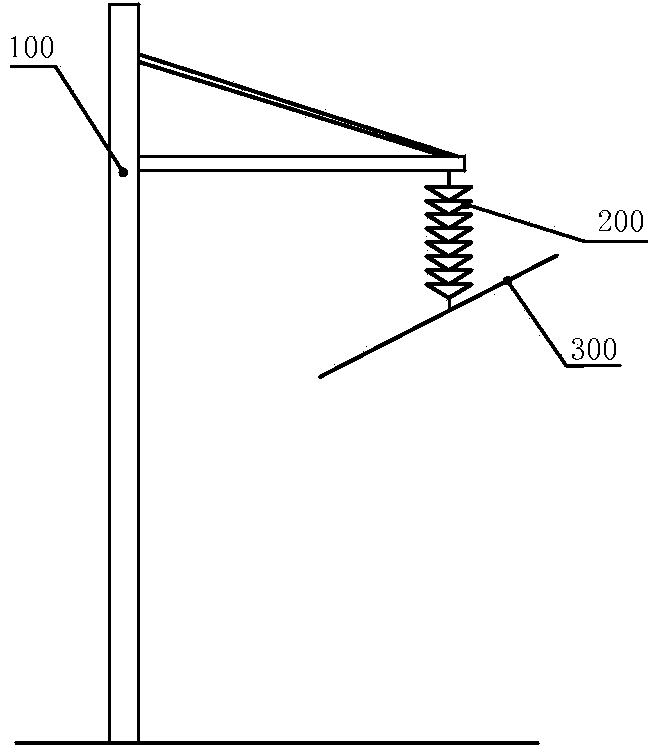

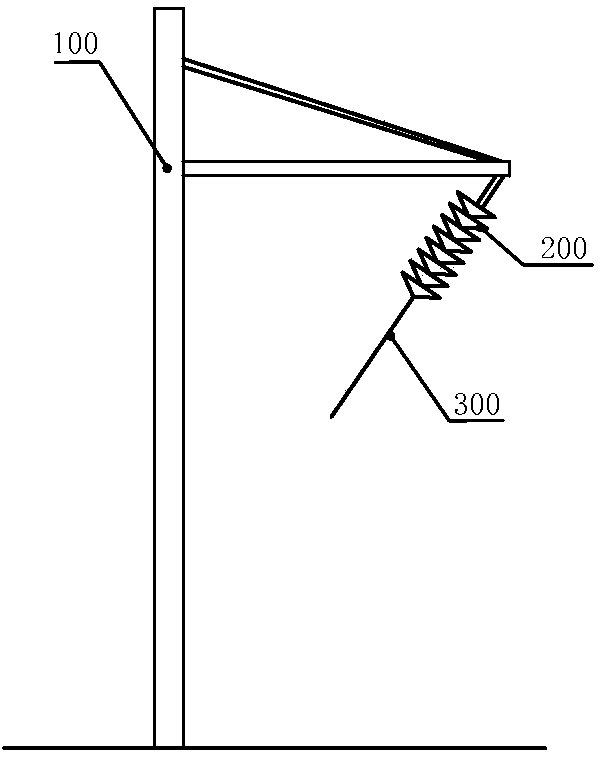

[0026] Such as Figure 7 As shown, a general grounding wire for a 110 kV overhead line tension tower has a hook head 1, an insulating rod 6, an annealed copper wire 9 and a cross bar 11. The hook head 1 is made of aluminum alloy material, which is light in weight and can meet the strength requirements. It is required that the upper part of the hook head 1 is a U-shaped opening for clamping the wire. One end of the annealed copper wire 9 is installed on the hook head 1, and the other end is connected to a ground chuck 10; one end of the cross bar 11 is fixed on the root of the hook head 1, and the other end is installed with an adjustment bracket 5 that can rotate around the cross bar 11 , the upper part of the insulating rod 6 is fixed on the adjustment bracket 5, and the insulating rod 6 has a hollow tubular structure. The center of the cross bar is provided with a screw nut; the screw rod 3 passes through the upper end of the screw nut to fix the lock block 2, the lower end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com