Multi-port energy conversion device

An energy conversion device, multi-port technology, applied in electrical components and other directions, can solve problems such as single energy conversion mode, and achieve the effects of eliminating friction loss, eliminating vibration and noise, and improving reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

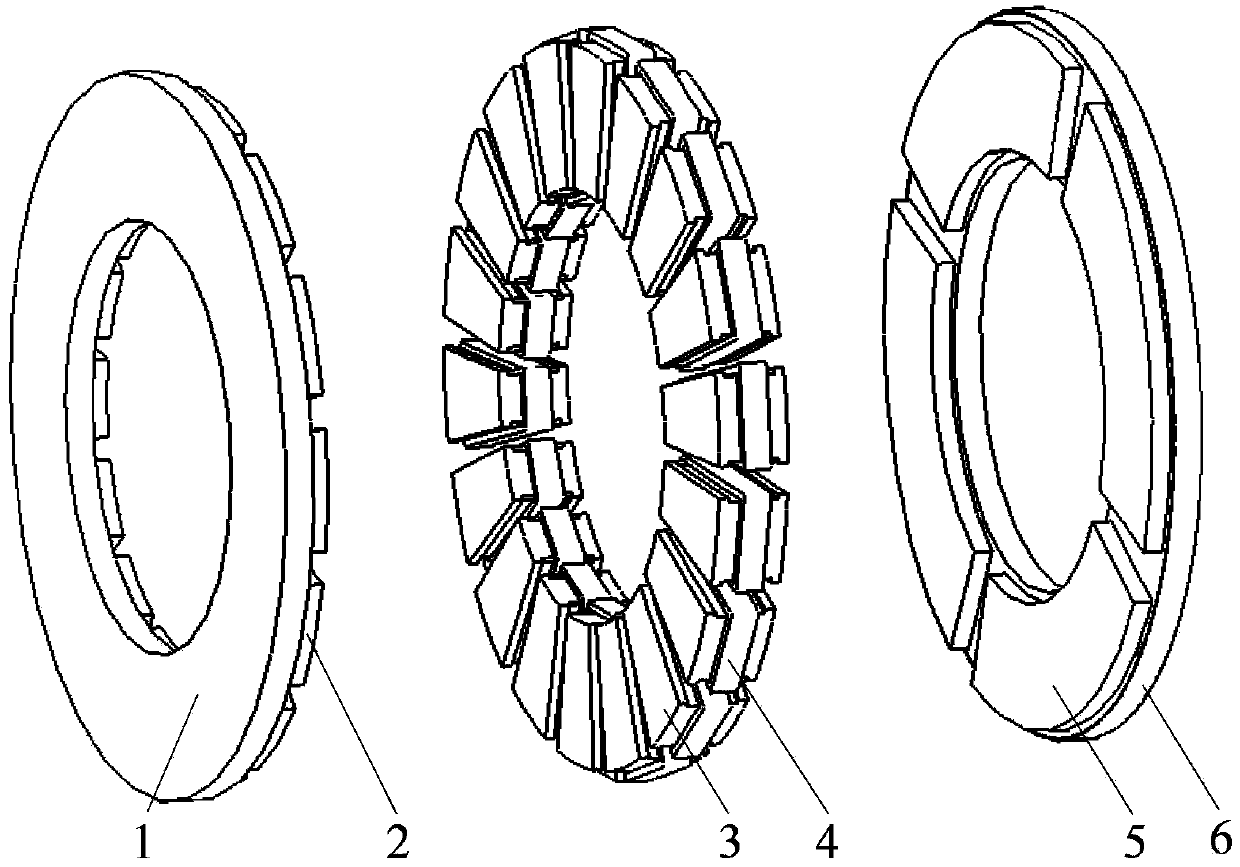

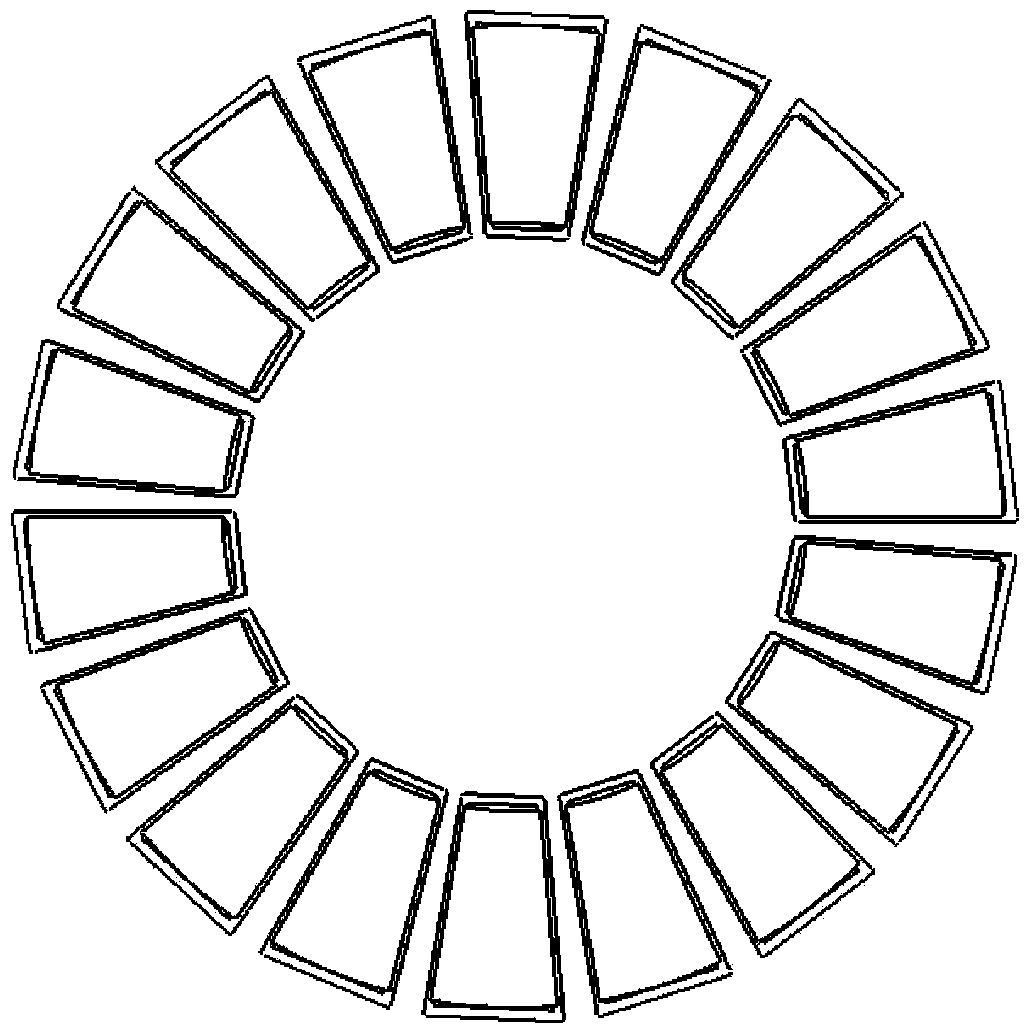

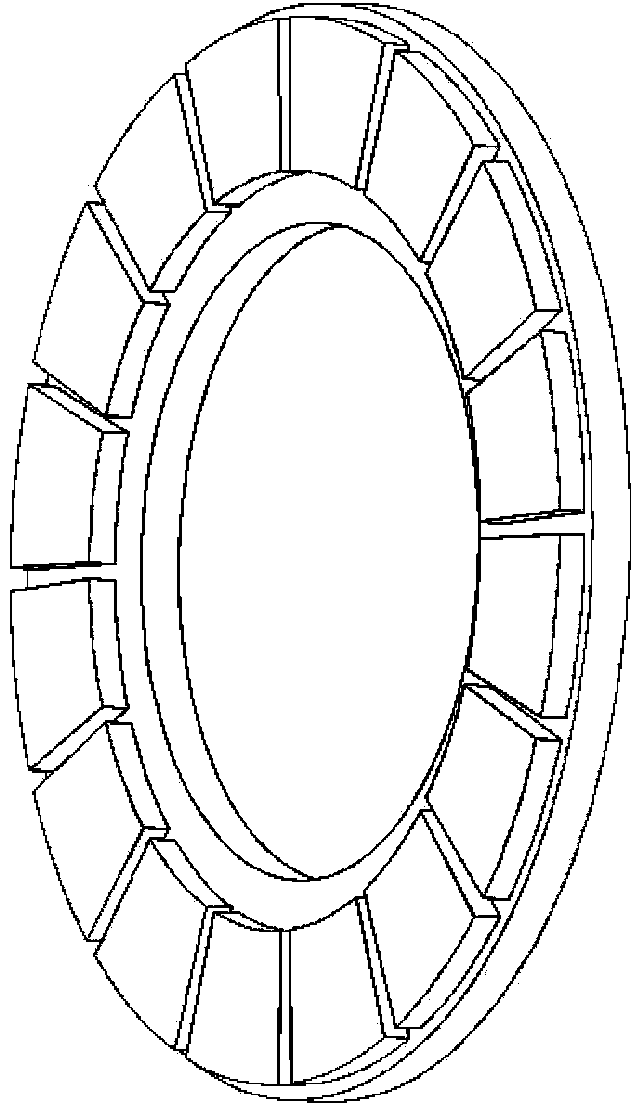

[0032] The multi-port energy conversion device includes a high-speed side rotor, a low-speed side rotor and a magnetic modulation mechanism. The high-speed and low-speed side rotors are separated on both sides of the magnetic modulation mechanism, and there is an air gap between them and the magnetic modulation mechanism. The space is symmetrical about the magnetic modulation mechanism. The axis coincides with the axis of the magnetic adjustment mechanism. Permanent magnets are respectively installed on the low-speed side rotor and the high-speed side rotor, and the high-speed side and low-speed side rotors are respectively connected with the high-speed and low-speed rotating shafts, and the two rotating shafts can rotate freely. The magnet adjustment block is made of magnetic material, and the armature winding is placed on the magnet adjustment block (such as figure 2 shown).

[0033] The number of adjustable magnet blocks Z, the number of 5 pole pairs of permanent magnets ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com