cam mechanism

A cam mechanism and cam technology, applied in the electromechanical field, can solve the problems of dynamic connection, mechanical parts friction damage, and cam mechanism component breakage, etc., and achieve the effects of high reliability, increased electromagnetic control force, and high output accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

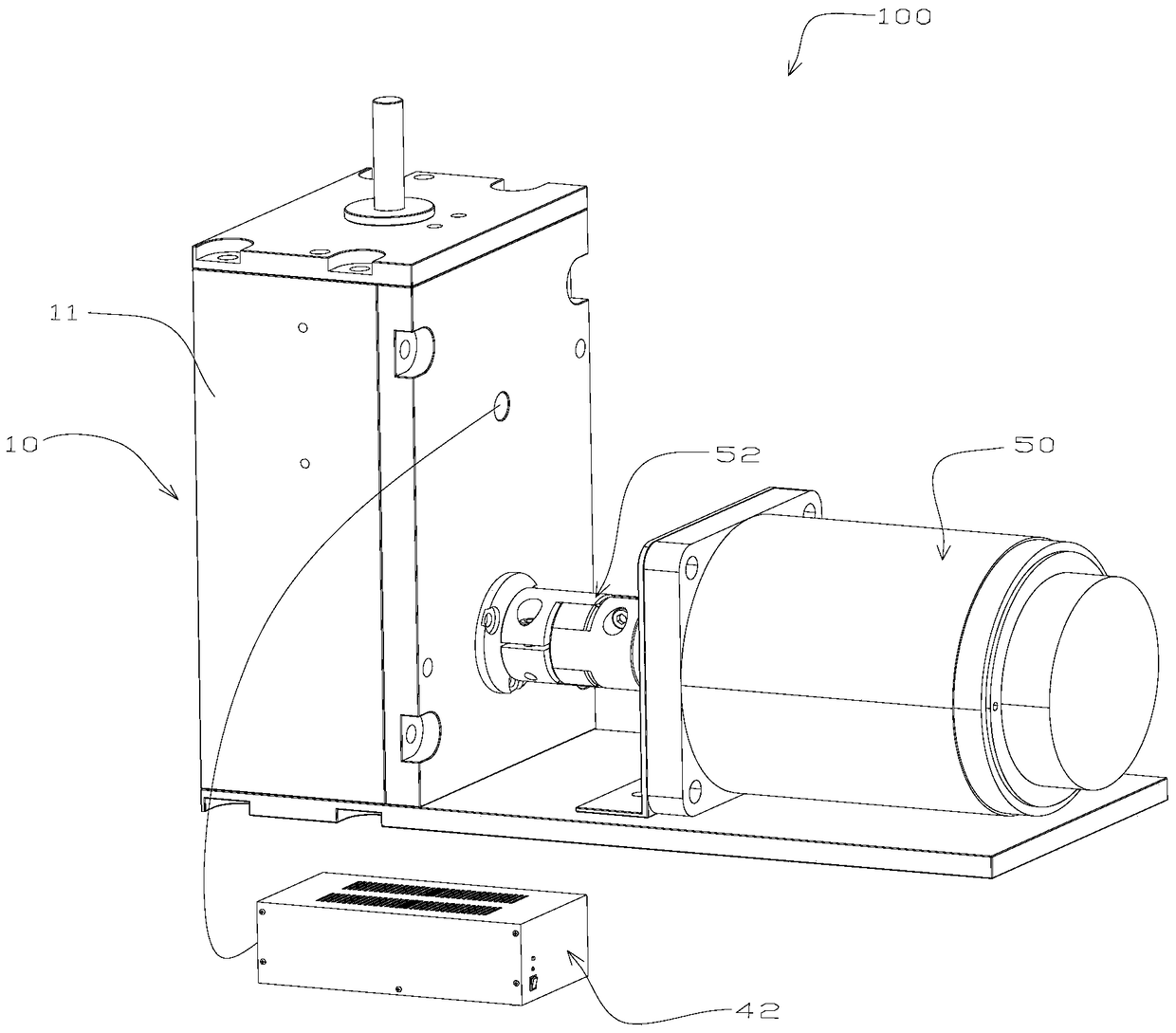

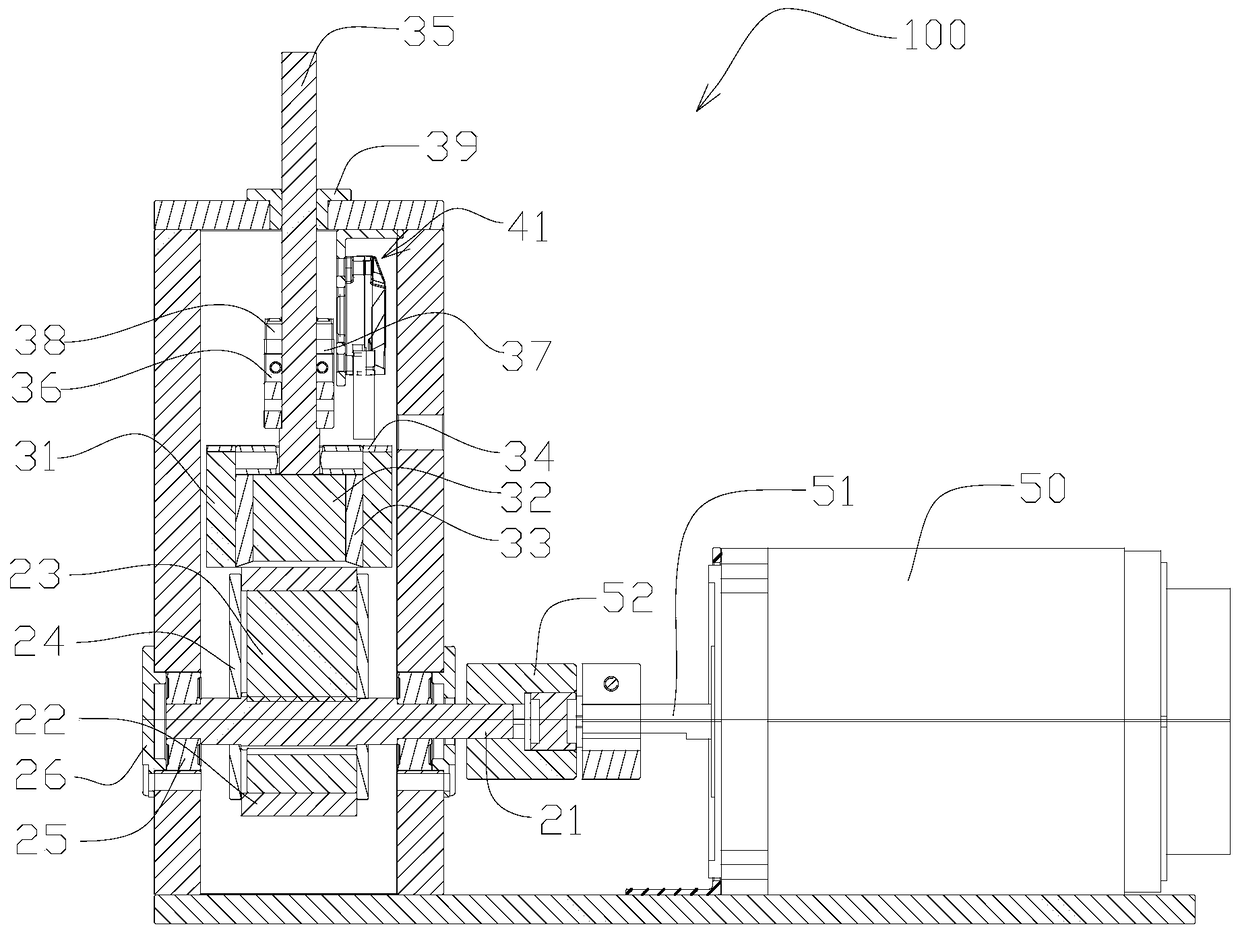

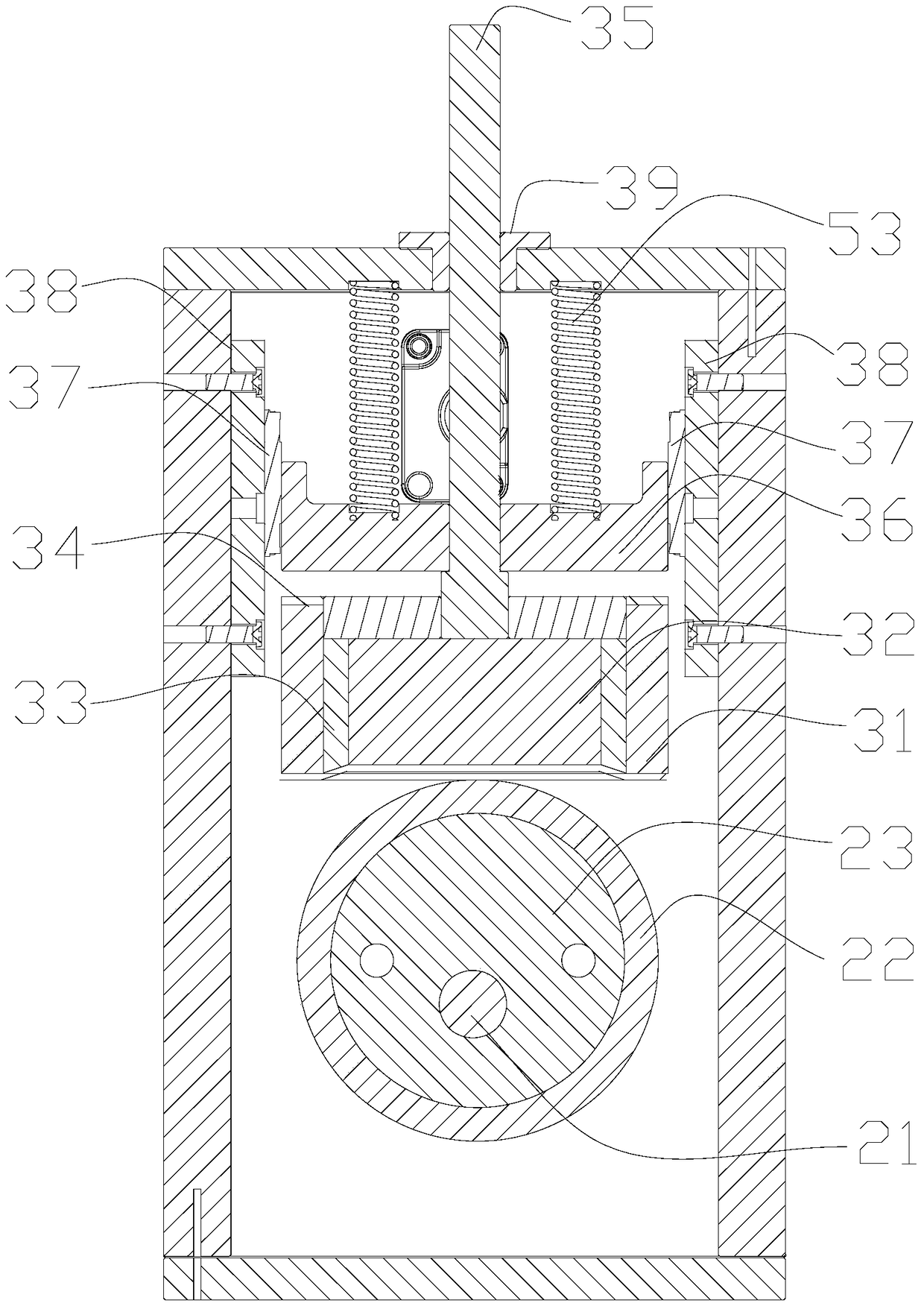

[0049] Preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings, so as to better understand the purpose, features and advantages of the present invention. It should be understood that the embodiments shown in the drawings are not intended to limit the scope of the present invention, but only to illustrate the essence of the technical solutions of the present invention.

[0050] The invention mainly relates to a non-contact magnetic levitation cam mechanism, which can be widely used in the fields of machine tools, textile machinery, light industry machinery, printing machinery, mechatronics assembly and the like.

[0051] The cam mechanism of the present invention generally includes a driving part and a driven part. The driving part includes a permanent magnet cam and a main shaft. The driven part includes a permanent magnet and an output shaft. The permanent magnet cam is fixedly connected to the main shaft, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com