Threshing and separating mechanism of corn harvester

A technology of threshing separation and harvester

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

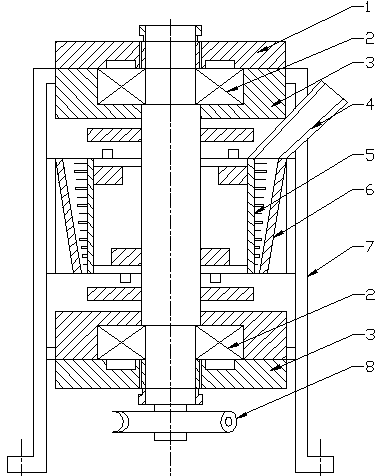

[0010] like figure 1 A threshing and separation mechanism of a corn harvester is shown, including a gland 1 , a main shaft 2 , a bearing 3 , a bearing seat 4 , a feeding port 5 , an inner drum 6 , an outer drum 7 , a fixed frame 8 and a flywheel 9 . The main shaft 2 is fixed on the fixed frame 8 through the bearing 3, the bearing seat 4 of the fixed bearing, and the pressure cover 1. The inner drum 6 is installed in the middle of the main shaft 1, and the outer drum 7 is installed on the fixing frame 8 outside the inner drum 6. On the fixing frame 8 A feed port 5 is opened to lead between the inner and outer drums, the lower end of the main shaft 2 is equipped with a flywheel 9; the outer wall of the inner drum is equipped with rotating blades; the inner wall of the outer drum 7 is equipped with a small convex head.

[0011] When the mechanism is working, the mixture of small strips, small pieces and broken pieces of corn cobs after being drilled enters between the inner and o...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap