Agricultural spraying machine

A technology of throwing machinery and power mechanism, which is applied in the direction of application, devices for catching or killing insects, and equipment for eliminating weeds. Self-weight, the effect of reducing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The principles and features of the present invention will be described below with reference to the accompanying drawings. The examples are only used to explain the present invention, but not to limit the scope of the present invention.

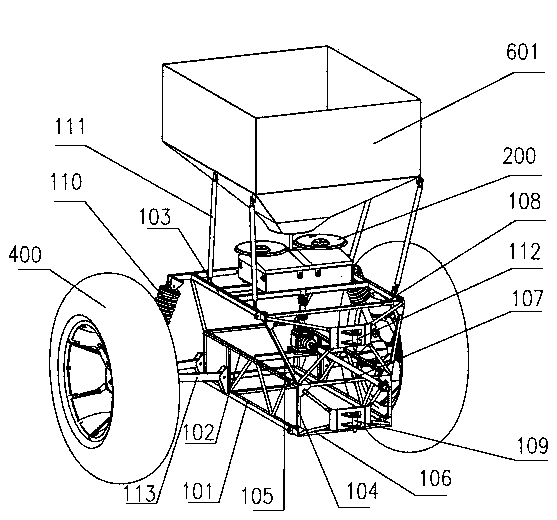

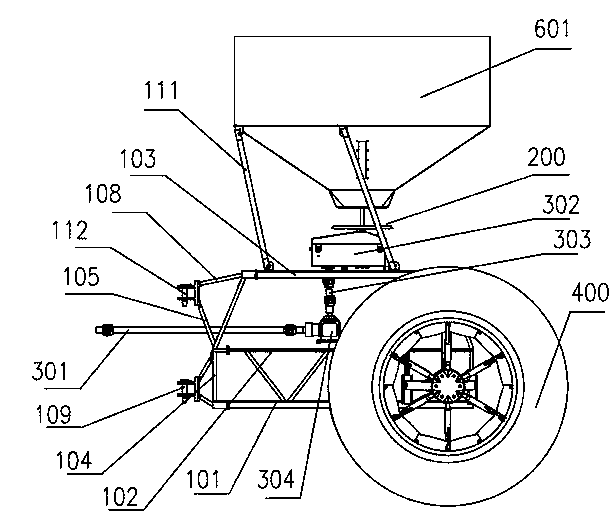

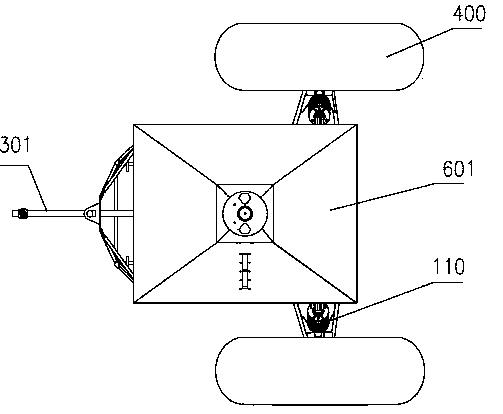

[0040] like Figure 1 to Figure 3 As shown, an agricultural throwing machine includes a frame body 100, a hopper 601, a throwing mechanism 200, a power mechanism 300 and a wheel body 400. The wheel body 400 is installed on both sides of the frame body 100, and the hopper 601 supports Above the frame body 100 , the throwing mechanism 200 and the power mechanism 300 are disposed below the hopper 601 and fixed on the frame body 100 , and the frame body 100 is a truss structure.

[0041]The frame body 100 includes a lower longitudinal beam 101, a middle longitudinal beam 102, an upper longitudinal beam 103, a lower column 104, an upper column 105, a lower beam 106, a middle beam 107, an upper beam 108 and a wheel body mounting frame 113; T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com