A lychee removing machine

A lychee and rack technology, which is applied in the design and manufacture of lychee removing machines, can solve the problems of low efficiency in removing lychees, increase management costs, and fail to keep up with the pace of production mechanization, and achieves simple structure, increased management costs, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

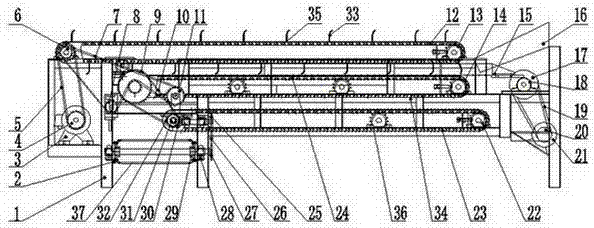

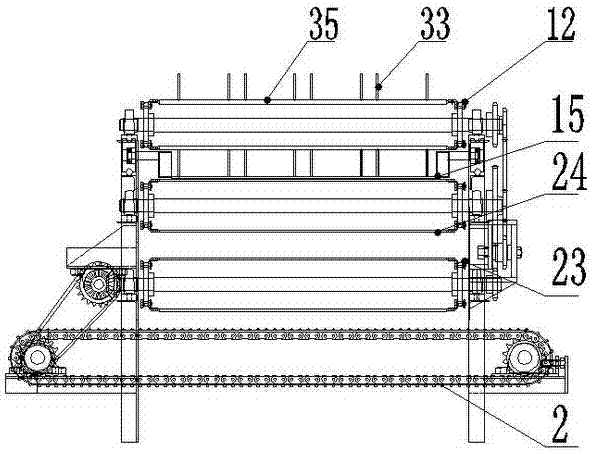

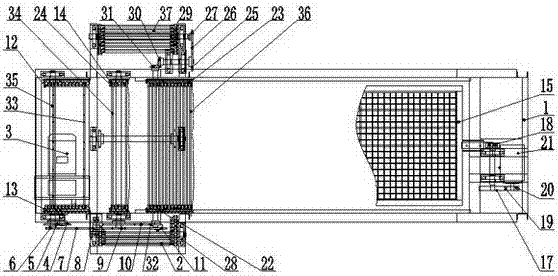

[0027] attached figure 1 A front view of an embodiment of the invention is given, with figure 2 A left side view of an embodiment of the invention is given, with image 3 It is a top view of an embodiment of the present invention. Refer to the attached drawings above.

[0028] All parts of the present invention are all made of metal. It mainly includes a frame 1, a main power device arranged on the frame 1, a branch removing device, a vibrating screening device, a branch scraping device and a fruit conveying device.

[0029] The active power device mainly comprises the main motor 3 that the main shaft is provided with the motor sprocket 4, and the main motor 3 through the active power chain 5 and the 13 motor sprocket 4 engaged with motor sprocket 4 and branch sprocket 13 of the active power chain 5 engaged.

[0030] The branch-picking device mainly includes the branch-picking sprockets fixed on both sides of the frame 1 13. Two-end meshing sprocket Two of 13 take...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com