Electromagnetic electric-pressure cooker

An electric pressure cooker and electromagnetic technology, which is applied to cooking utensils, household appliances, applications, etc., can solve the problems of poor heat dissipation effect of the coil, no heat dissipation structure, and small space, so as to improve the heat dissipation effect, strengthen the heat dissipation performance, and increase the service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] The present application will be further described in detail below with reference to the embodiments and drawings, but the implementation manner of the present application is not limited thereto.

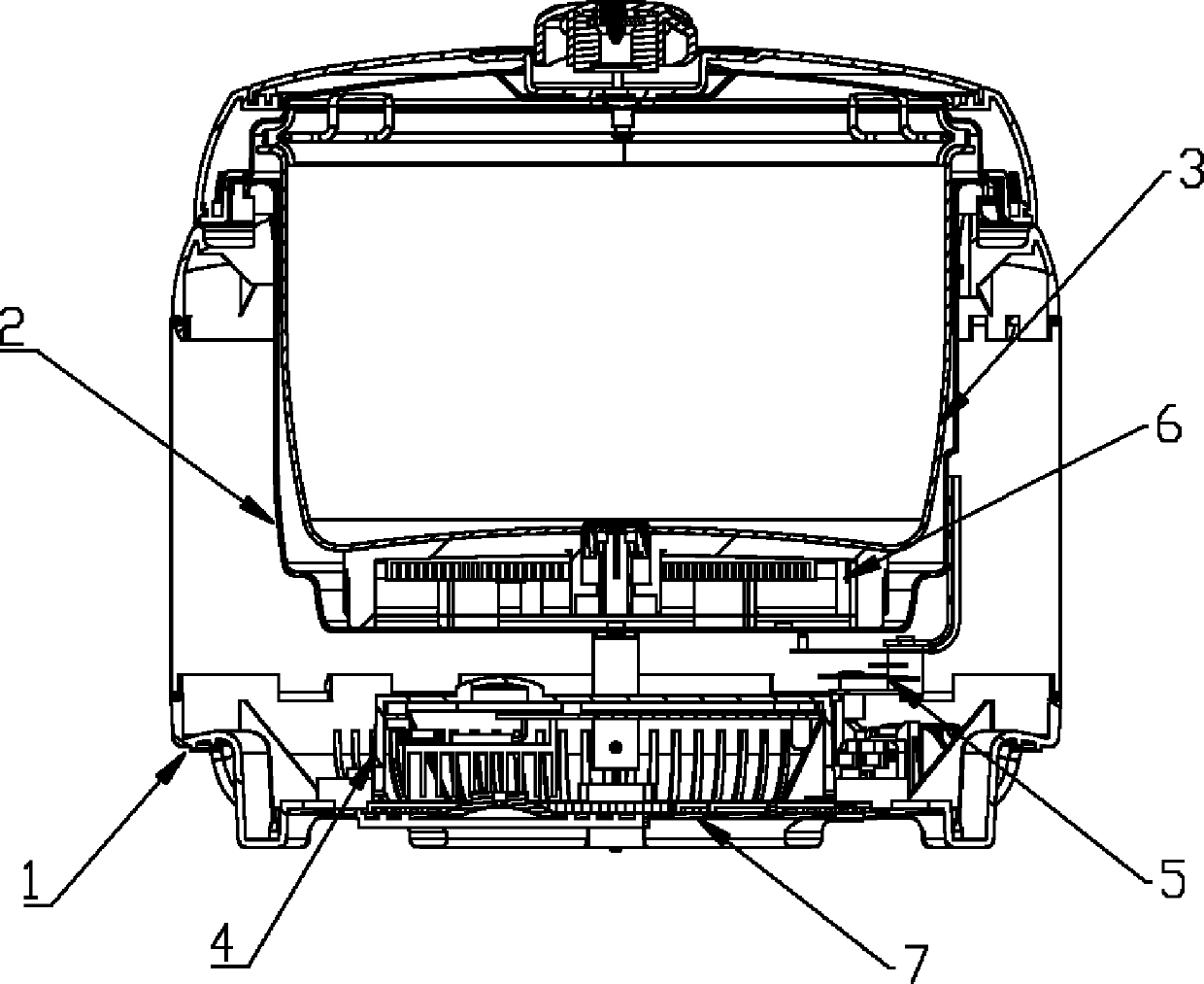

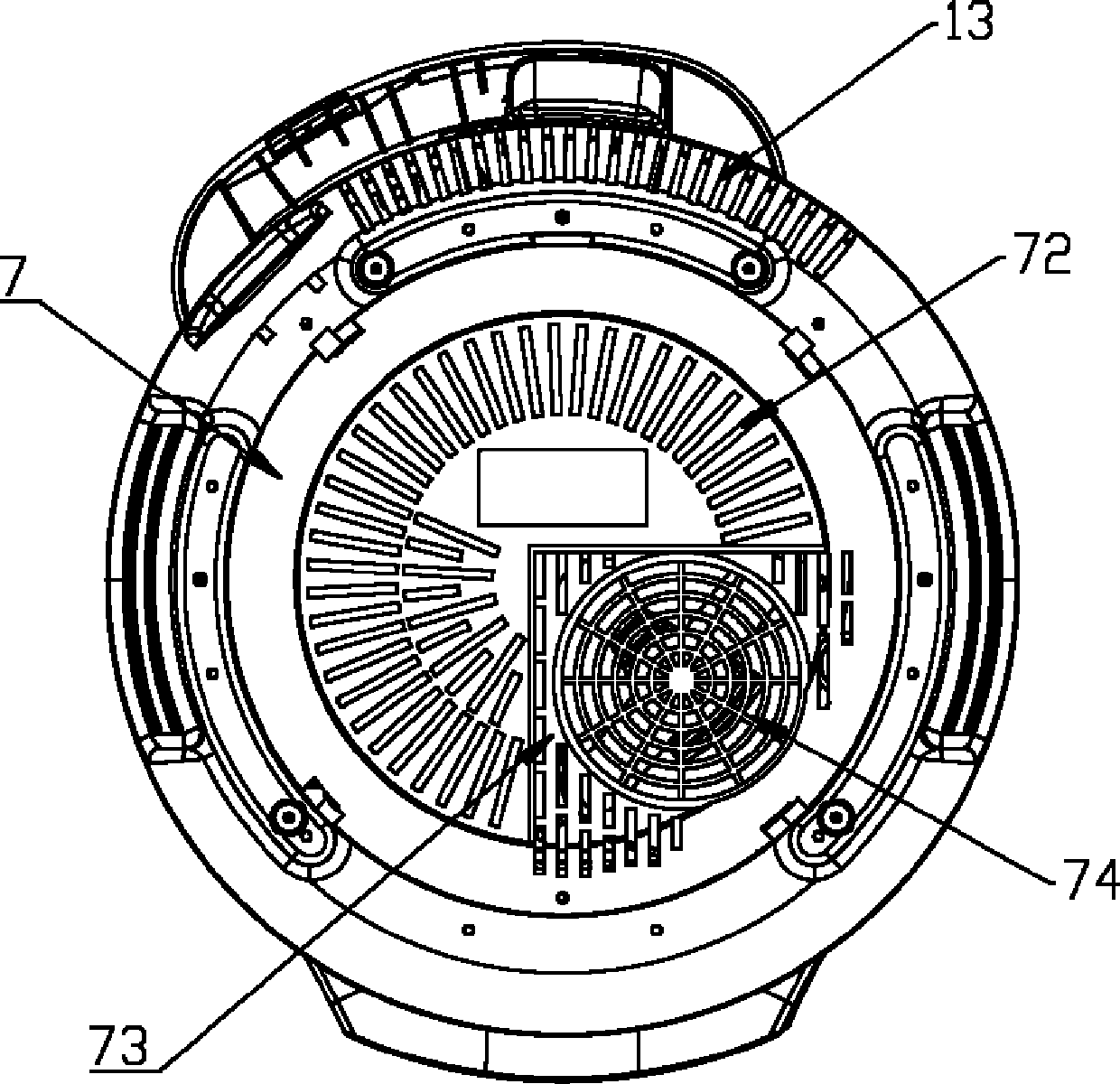

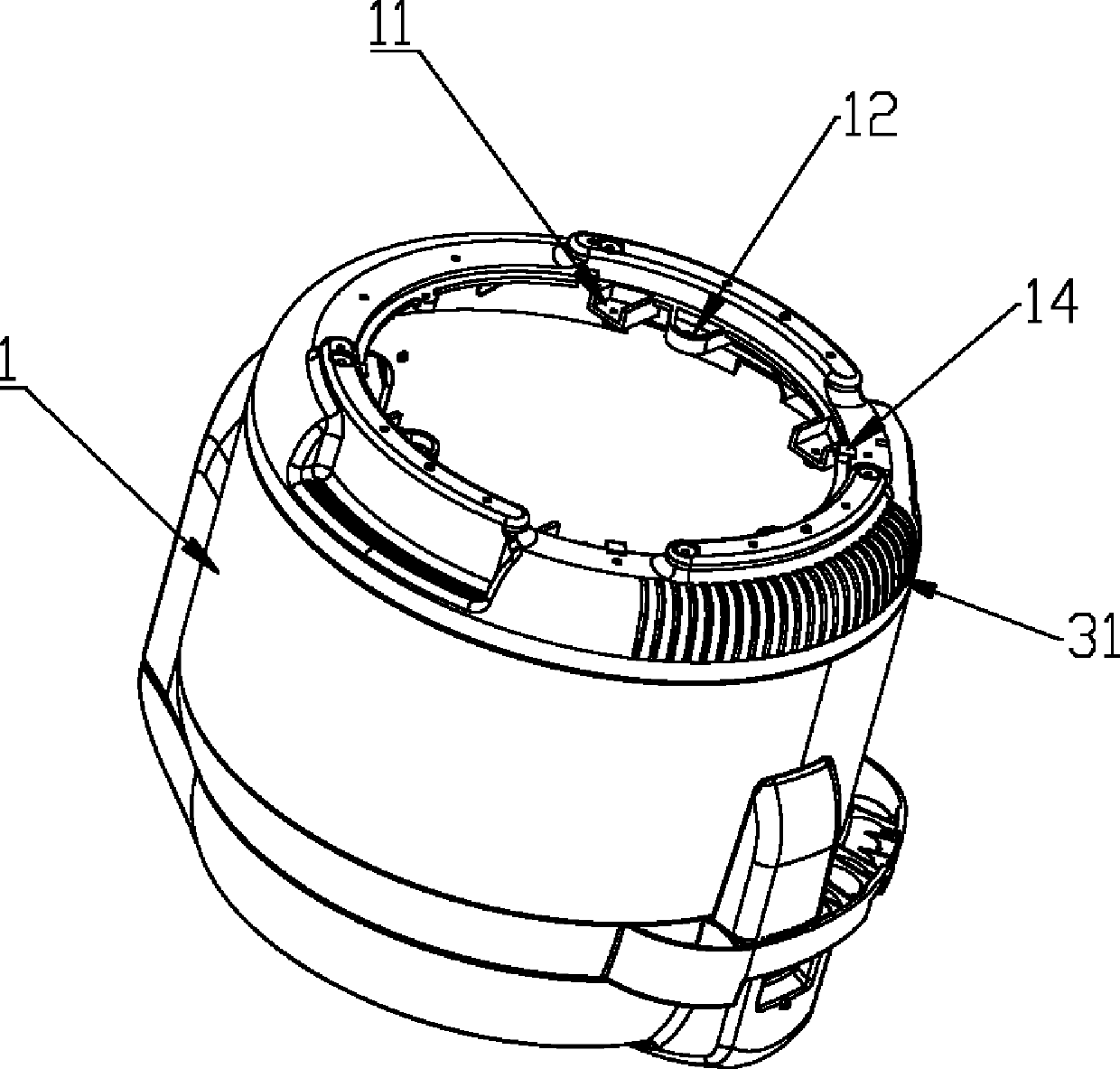

[0061] A kind of electromagnetic electric pressure cooker of the present application, such as Figure 1 to Figure 10 As shown, it includes a base 1, a bottom cover 7 connected to the base 1, an outer cover 2 and an inner container 3 arranged on the base 1, a power supply box 4 and a pressure switch assembly 5 are arranged inside the base 1, and the pressure switch assembly 5 is fixed on the outer cover 2, to control the pressure in the whole pot, an electromagnetic heating plate 6 is arranged between the outer cover 2 and the inner container 3, and the above-mentioned technical features are identical in structure with the electromagnetic electric pressure cooker in the prior art.

[0062] Compared with the prior art, one of the innovative points of the present application is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com