Combined drying tunnel

A combined type and drying tunnel technology, which is applied in the direction of pretreatment surface, coating, surface coating liquid device, etc., can solve the problems of cumbersome operation, adverse effect on product quality, and reduced production efficiency, so as to simplify the process flow, Improved quality and ease of operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

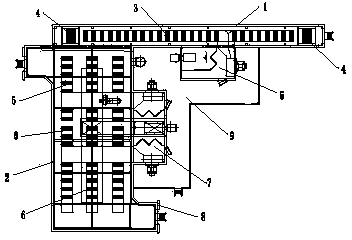

[0010] Combine below figure 1 Specific description embodiment:

[0011] A combined drying tunnel, characterized in that the combined drying tunnel is composed of a moisture drying device 1 and a curing device 2, the moisture drying device 1 and the curing device 2 are connected, and the The moisture drying device 1 comprises a drying tunnel chamber body 3, the two ends of the drying tunnel chamber body 3 are provided with a drying tunnel air curtain chamber 4, and the drying tunnel chamber body 3 The side part is provided with the drying oven heating chamber 5 that can heat the drying oven chamber body 3, and the described curing device 2 includes a curing oven chamber body 6, and the side of the curing oven chamber body 6 is A curing oven heating chamber 7 which can heat the curing oven chamber body 6 is provided at the top, and a curing oven moving door 8 is opened on the side of the curing oven chamber body 6 .

[0012] In a preferred manner, an inspection platform 9 is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com