Swivel joint rotary flushing device

A technology for rotary joints and flushing devices, applied in chemical instruments and methods, cleaning methods and utensils, cleaning methods using liquids, etc., can solve problems such as small rotary torque, improve efficiency, simple structure design, and improve the overall quality level Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

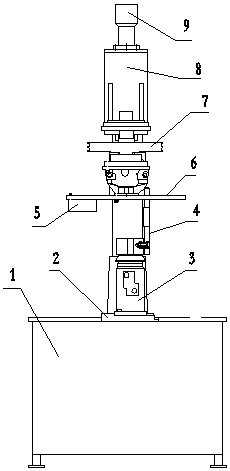

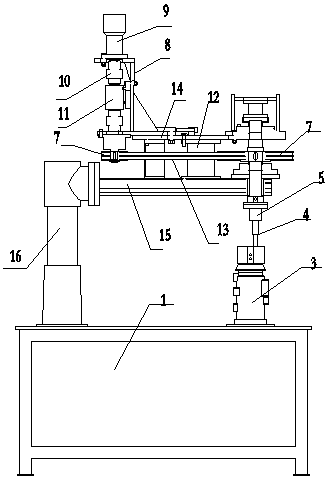

[0015] Such as figure 1 , 2 As shown, a swivel joint rotary flushing device of the present invention includes a workbench 1 on which a rocker arm and a swivel joint fixing seat 2 are arranged. The rotary joint 3 to be tested is fixed on the rotary joint fixing seat 2 by bolts.

[0016] The rocker arm is provided with a vertical rotating shaft and a driving device 9 that drives the rotating shaft to rotate axially through a transmission device. The rotating shaft is connected with a flushing oil distribution block 5 and a rotary housing push rod 4. In order to facilitate installation, the lower part of the rotating shaft The rotating disk 6 is connected, and the flushing oil separation block 5 and the rotary housing push rod 4 are connected on the rotating disk 6 . When the rotating shaft rotates, the rotating disc 6, the flushing oil separating block 5 and the rotary housing push rod 4 rotate together with the rotating shaft.

[0017] The flushing oil distribution block 5 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com