Device for removing rough casting plane fins

A blank and flat technology is applied in the field of devices for removing flat seams on camshaft castings. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

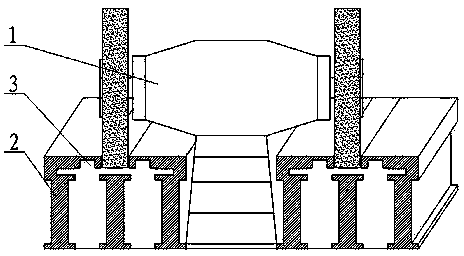

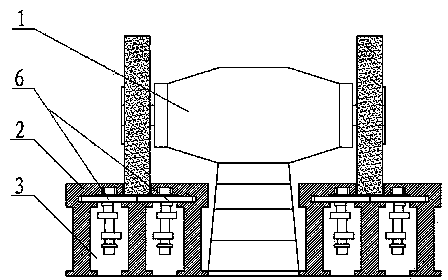

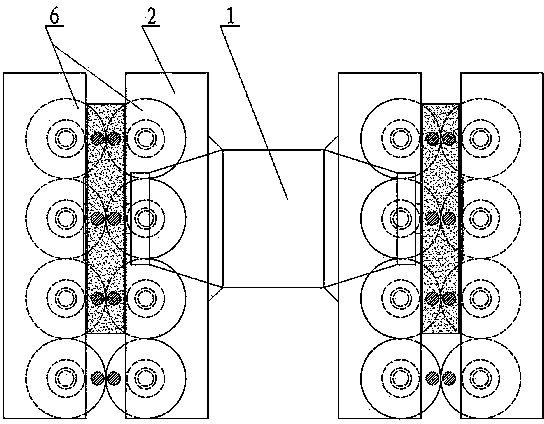

[0015] Such as figure 1 , figure 2 , image 3 A device for removing the plane seams of casting blanks is shown, which includes a grinder 1 and a guide rail 2. The guide rail 2 is provided under the grinding wheels on both sides of the grinder 1, and the entire base of the grinder 1 and the guide rail 2 are in line with the horizontal plane. The installation angle is 5 degrees; the guide rail 2 runs through front and back to form a limit groove 3, and is provided with a material inlet 4 and a material outlet 5.

[0016] The upper surface of the guide rail 2 is provided with grooves for embedding the grinding wheels on both sides of the grinder 1 .

[0017] The shape of the limiting groove 3 is set according to the shape of the workpiece 6 .

[0018] Such as Figure 4 , Figure 5 As shown, the feed port 4 is slightly higher than the discharge port 5, which facilitates the sliding of the workpiece 6.

[0019] Such as figure 1 The device shown is a device for removing the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com