An embedded system-based CNC drilling machine for threaded holes and its control method

An embedded system and CNC drilling machine technology, applied in boring/drilling, drilling/drilling equipment, manufacturing tools, etc., can solve the problem of inability to measure the processing depth, inability to remove debris in the hole conveniently, and inability to use computer control And other problems, to reduce personnel and tedious labor, protect the tap, improve the effect of thread quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

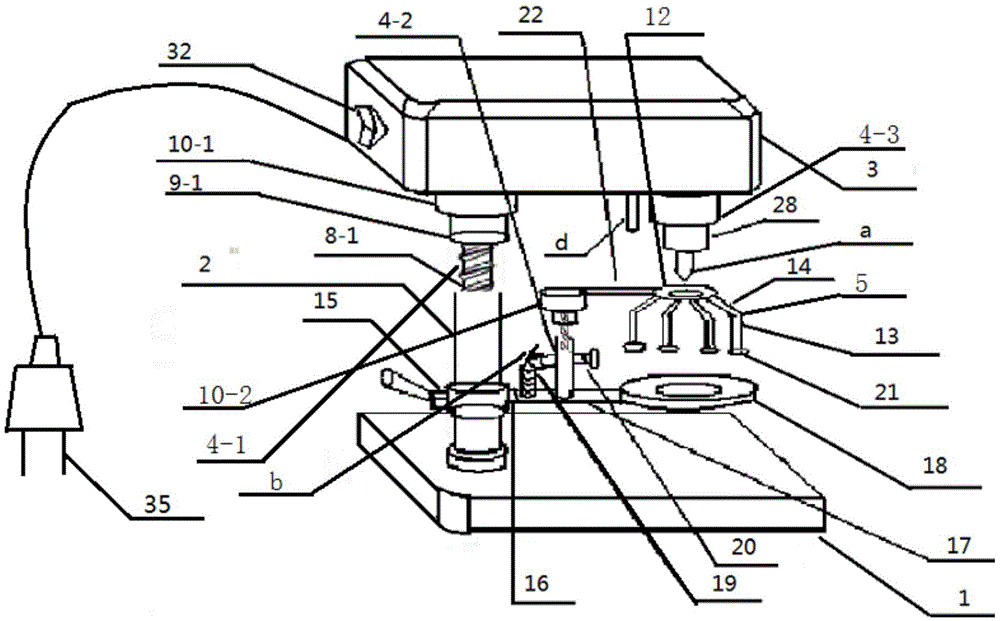

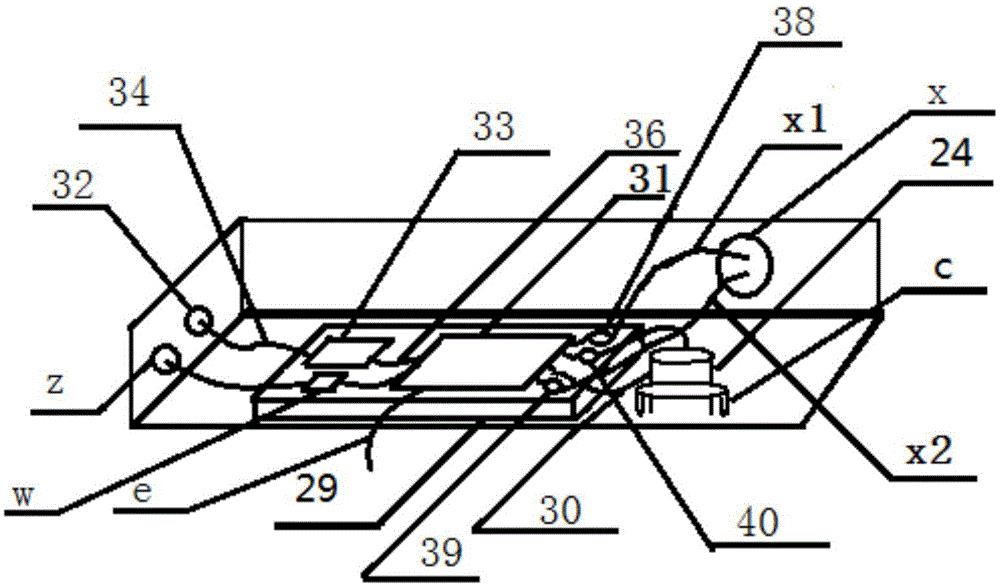

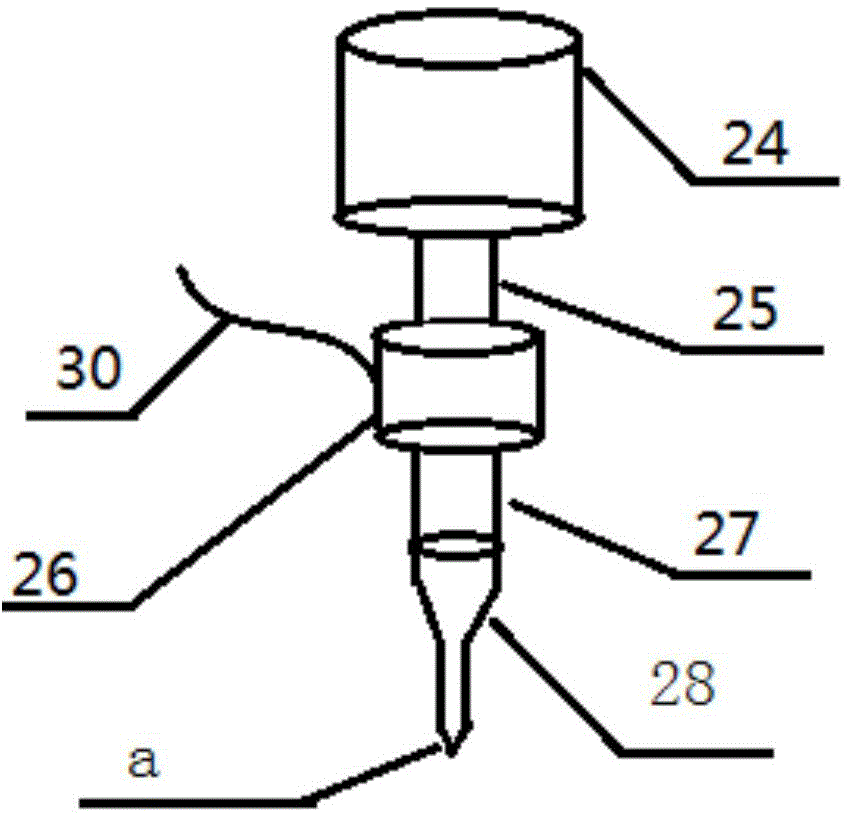

[0039] figure 1 A structural schematic diagram of the threaded hole CNC drilling machine based on the embedded system of the present invention is given; figure 2 It is the internal structural diagram of the cabinet of the threaded hole CNC drilling machine of the present invention; image 3 It is a structural schematic diagram of the main electric mechanism of the threaded hole CNC drilling machine of the present invention; Figure 4 It is a structural schematic diagram of the first transmission mechanism of the threaded hole CNC drilling machine of the present invention; Figure 5 It is a structural schematic diagram of the second transmission mechanism of the threaded hole CNC drilling machine of the present invention; Figure 6 It is a structural schematic diagram of the claw-shaped workpiece pressing mechanism of the threaded hole CNC drilling machine of the present invention.

[0040] An embodiment of the present invention is based on an embedded system-based threaded...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com