Optical anti-fake element and production method thereof

An optical anti-counterfeiting and component technology, applied in optical components, optics, diffraction gratings, etc., can solve problems affecting anti-counterfeiting effects, color differences, increasing process complexity and cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The optical anti-counterfeiting element and the manufacturing method thereof according to the present invention will be described in detail below with reference to the accompanying drawings.

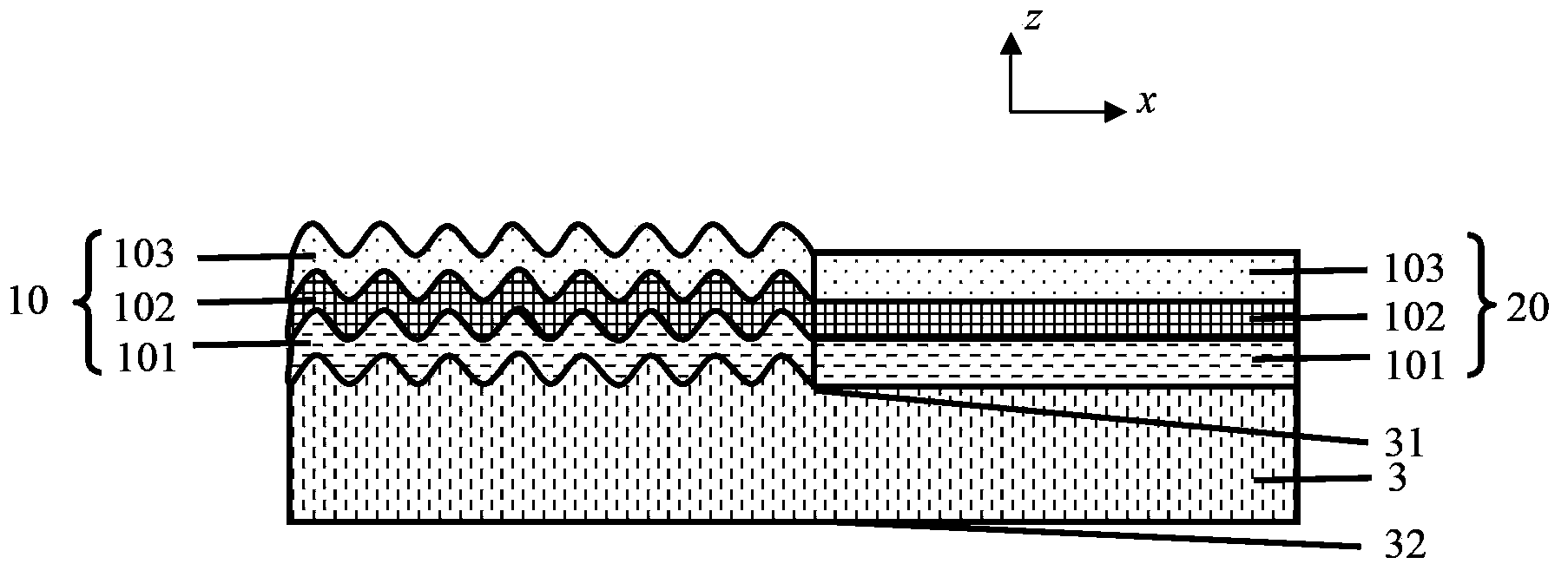

[0022] like figure 1 As shown, the optical anti-counterfeiting element according to an embodiment of the present invention includes a substrate 3, the substrate 3 includes a first surface 31 and a second surface 32, and a partial area on the first surface 31 is subwavelength micro-relief Structure, partial area is flat surface structure. A first dielectric layer 101, a second dielectric layer 102 and a third dielectric layer 103 are sequentially stacked on the sub-wavelength micro-relief structure and the flat surface structure area, thereby forming the interference structures 10 and 103 located in the sub-wavelength micro-relief structure area, respectively. The interference structure 20 in the region of the flat surface structure. in, figure 1 The coordinate z in represents t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com