Winding device with locking mechanism for creels

A technology of a winding device and a locking mechanism, applied in the directions of transportation and packaging, thin material handling, conveying filamentous materials, etc., can solve the problem of reducing the output of winding machines or spinning machines, time consuming, driving rollers or bobbin retention. damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

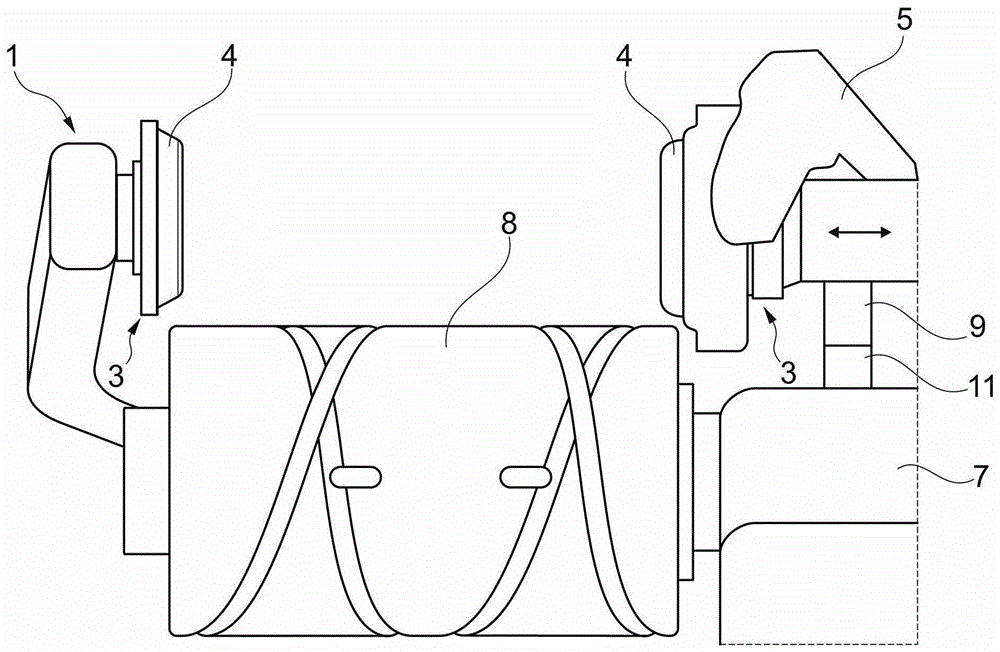

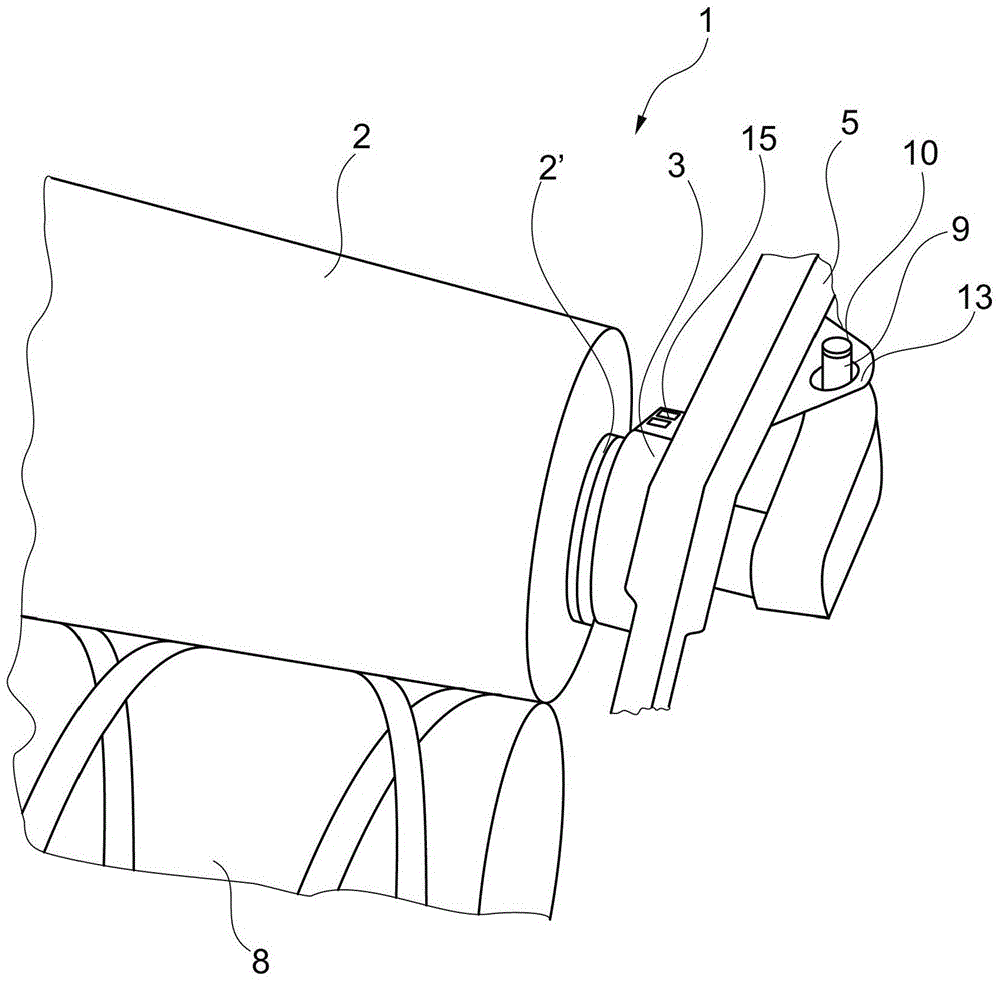

[0029] figure 1 and figure 2 A schematic view of the creel 1 of the winding device is shown. In this type of winding device, the yarn is wound to form a cross-wound bobbin 2 . The cross-wound bobbins 2 are held by their bobbins 2' in the creel 1 during the spinning or winding process and are thus driven by means of frictional engagement by bobbin drive rollers 8, here for example guide drums. In addition to being driven, the yarn guide drum 8 ensures that the yarn is wound on the cross bobbins 2 in the form of cross layers. The creel 1 is pivotably mounted about a pivot 6 .

[0030] Furthermore, a creel 1 of this type generally has bobbin holders 3 with bobbin holder plates 4, between which bobbins 2' are clamped. By means of the creel opening lever 5, the bobbin holder 3 located on the right in front view can be displaced axially so that the bobbin 2' of the cross-wound bobbin 2 can be inserted.

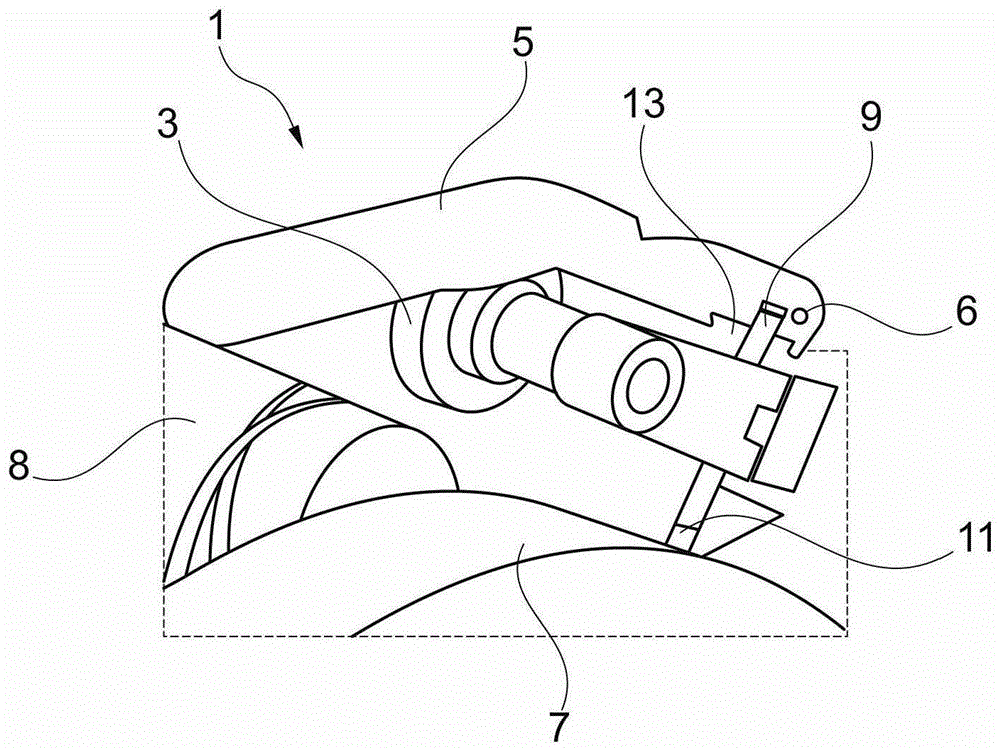

[0031] image 3 and Figure 4A detailed view of the device according to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com