Guide mechanism of pressure cover of star wheel group of automatic capping machine

A technology of guiding mechanism and capping machine, which is applied in the direction of capping the container tightly, bottle/container cap, bottle filling, etc. It can solve the drift of the can cap, the coaxial deviation between the can cap and the aerosol can, and the long capping stroke and other problems to achieve the effect of good operability, overcoming quality problems, and high reproduction accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

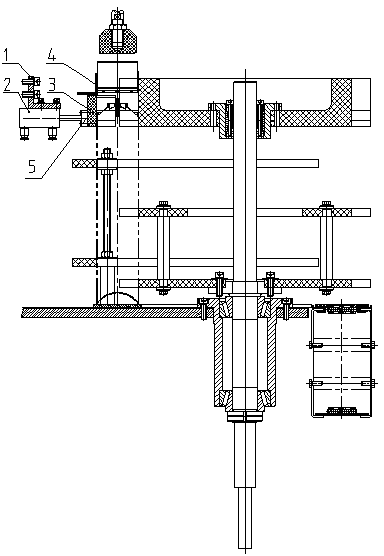

[0009] The star wheel group gland guide mechanism of the automatic capping machine, the guide mechanism is arranged on the side of the cap star wheel, the guide mechanism includes the cylinder 2, the connecting plate 5 and the guide body 4, and the cylinder 2 is fixed Connected on the cylinder mounting plate 1, a guide sleeve 3 is fixed on the connecting plate 5 at the front end of the piston rod, and a guide body 4 is arranged on the guide sleeve 3. The guide sleeve 3 is an oil nylon cuboid with a semicircular groove, and the semicircular groove There is a groove in the middle, and the semicircular groove of the guide sleeve 3 and the semicircular groove on the circumference of the gland star wheel form a concentric cylindrical hole.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com