Preparation method of acrylonitrile butadiene rubber

A technology of nitrile butadiene rubber and vinyl nitrile, which is applied in the field of preparation of highly stable nitrile butadiene rubber, can solve the problems of unfavorable large-scale production and troublesome operation, and achieve the effects of fast polymerization rate, improved stability and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

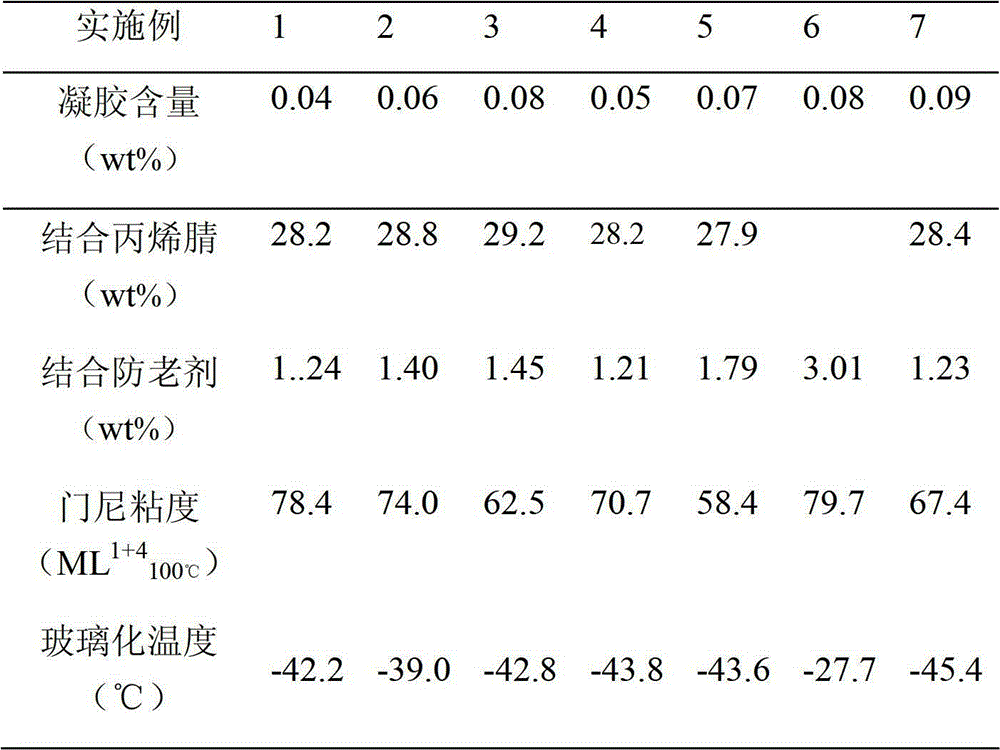

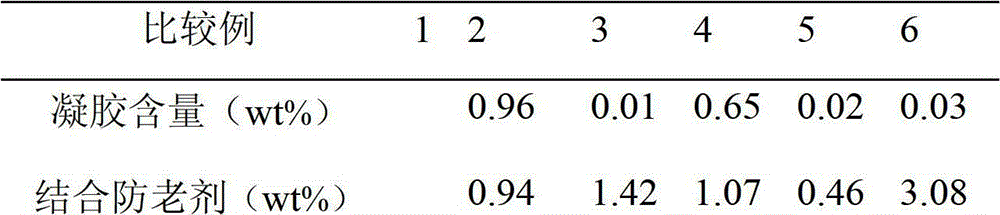

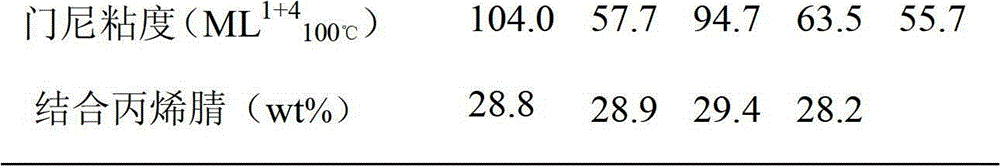

Examples

Embodiment 1

[0049] In the reactor, add water 175wt%, disproportionated potassium rosinate 3.50wt%, fatty acid soap 1.50%, β-naphthalene sulfonate sodium formaldehyde condensate 0.5wt%, potassium chloride 0.25wt%, EDTA 0.015wt%, sulfurous acid 0.015wt% iron, 0.06wt% diabolite, 0.30wt% tert-dodecyl mercaptan, 2.0wt% N-(p-anilinophenyl) methacrylamide, 27.0wt% acrylonitrile; vacuumize for 25min , add 0.03wt% oxygen scavenger solution, then add 70.5wt% butadiene, stir and control the temperature to 15-18°C, add 0.09wt% initiator dicumyl peroxide, polymerize for 1.5h, then cool down To 5 ~ 8 ℃, carry out polymerization;

[0050] When the reaction was carried out for 3.5 hours, the measured conversion rate was 34.1%, and 25% of water was added continuously, 0.95wt% of disproportionated abietate potassium, 0.015wt% of β-naphthalenesulfonic acid sodium formaldehyde condensate, potassium chloride 0.05wt%, EDTA The mixed solution of 0.005wt% was added for 1.5 hours; when the conversion rate was 38...

Embodiment 2

[0054] In the reactor, add water 175wt%, disproportionated potassium rosinate 4.75wt%, β-naphthalene sulfonate sodium formaldehyde condensate 0.3wt%, potassium chloride 0.25wt%, EDTA 0.025wt%, EDTA (FeNa) 0.015wt% , Diaobai block 0.10wt%, tert-dodecyl mercaptan 0.32wt%, N-(p-anilinophenyl) methacrylamide 2.5wt%, acrylonitrile 28.5wt%; vacuum 25min, add 0.03wt % oxygen scavenger solution, then add butadiene 68.5wt%, stir and control the temperature to 15-18°C, add the initiator dicumyl peroxide 0.085wt%, after polymerization for 2 hours, cool down to 5-8°C , for aggregation;

[0055] When the reaction was carried out for 3.25 hours, the measured conversion rate was 33.4%, and 25% of water was continuously added, 0.9wt% of disproportionated abietate potassium, 0.1wt% of β-naphthalenesulfonate sodium formaldehyde condensate, potassium chloride 0.05wt%, EDTA 0.006wt% mixed solution for 2.0 hours; when the conversion rate is 41.5%, a mixture of 0.10wt% tertiary-dodecylmercaptan an...

Embodiment 3

[0058] In the reactor, add 175wt% of water, 4.75wt% of disproportionated potassium abietate, 0.35wt% of β-naphthalenesulfonate sodium formaldehyde condensate, 0.30wt% of potassium chloride, 0.025wt% of EDTA, 0.0125wt% of EDTA (FeNa) , Diaobai block 0.175wt%, tert-dodecyl mercaptan 0.42wt%, N-(p-anilinophenyl) methacrylamide 2.0wt%, acrylonitrile 27.0wt%; vacuum 30min, add 0.03wt % oxygen scavenger solution, then add 70.5wt% butadiene, stir and control the temperature to 15-18°C, add the initiator dicumyl peroxide 0.10wt%, after polymerization for 3 hours, cool down to 5-8°C , for aggregation;

[0059] When the reaction was carried out for 3.10 hours, the measured conversion rate was 37.9%, and 25% of water was added at one time, 0.85wt% of disproportionated abietate potassium, 0.125wt% of β-naphthalenesulfonate sodium formaldehyde condensate, 0.06wt% of potassium chloride, A mixed solution of 0.005wt% EDTA; when the conversion rate is 43.1%, a mixture of 0.12wt% tert-dodecylm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com