Ethylene propylene diene monomer and preparation method and application thereof

A EPDM rubber and ethylene technology, applied in the direction of rolling resistance optimization, road transportation emission reduction, etc., can solve the problems of unsuitable continuous vulcanization process, prone to scorch, high degree of cross-linking, high polymerization activity, improved The effect of scorch performance and high conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

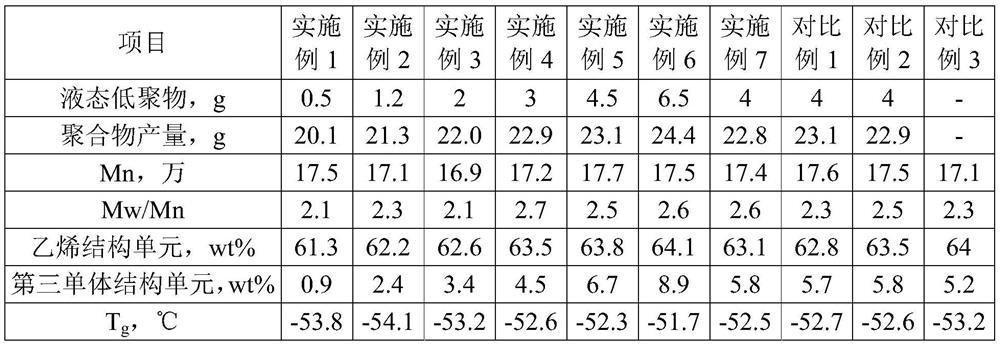

Embodiment 1-6

[0053] In a 2-liter stainless steel stirred tank, under the protection of high-purity nitrogen, add 1000 ml of hexane, 1 mmol of ethyl trichloroacetate, and 2 mmol of sesquialuminum Al 2 (C 2 H 5 ) 3 Cl 3 , a certain amount of liquid butadiene-styrene oligomer A (molecular weight 2000, the content of styrene structural unit is 20wt%, the content of 1,2-structure in butadiene structural unit is 69wt%), 0.1mmol of VOCl 3 , the pressure of feeding the mixed gas reaches 0.6 MPa, the molar ratio of ethylene and propylene in the mixed gas is 1:5, the hydrogen content is 0.5 mol%, and the mixture is stirred and reacted at 10° C. for 15 minutes. After the polymerization, 1 ml of terminator ethanol and 1 ml of anti-aging agent 1076 (10wt% hexane solution) were added, and then coagulated and dried in a conventional manner to obtain EPDM-A1 to EPDM-A6 EPDM rubbers, GPC, NMR , DSC test, the results are shown in Table 1.

Embodiment 7

[0055] EPDM was prepared according to the method of Preparation Example 1, except that: in the liquid styrene-butadiene rubber oligomer, the content of 1,2-structure in the butadiene structural unit was different from that of Preparation Example 1, which was 85% by weight. Preparation of EPDM-A7.

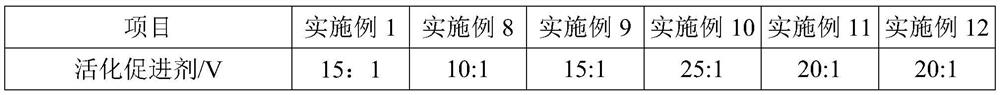

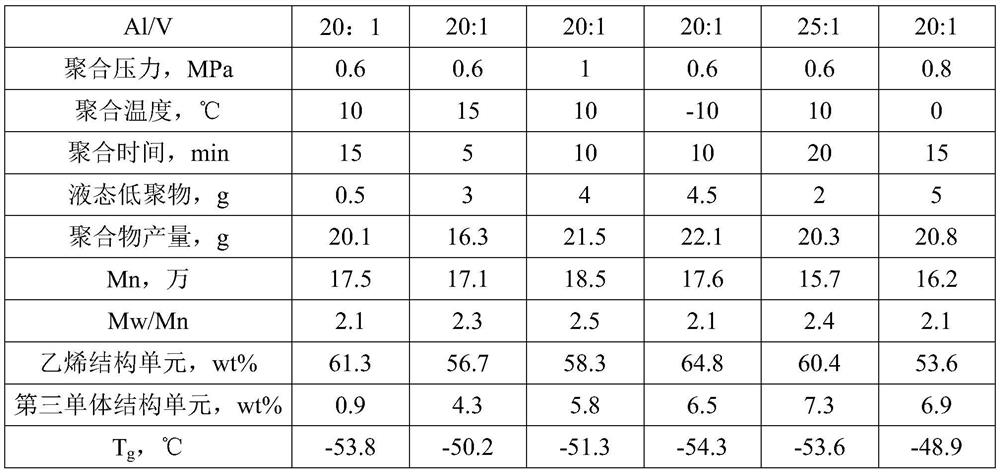

Embodiment 8-12

[0065] EPDM was prepared according to the method of Example 1. The difference was that the polymerization conditions were different. EPDM-A8, EPDM-A9, EPDM-A10, EPDM-A11, EPDM-A12 were prepared. The polymerization conditions and the performance parameters of EPDM were shown in Table 2. Show.

[0066] Table 2

[0067]

[0068]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com