Weathering anticorrosive resin for improving crosslink density of coating film, preparation method and application thereof

A technology of cross-linking density and anti-corrosion resin, applied in the direction of anti-corrosion coatings, etc., can solve problems such as difficult to meet the mechanical coating requirements of tobacco, tobacco deterioration, etc., achieve good weather resistance, increase cross-linking density, and simple synthesis process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

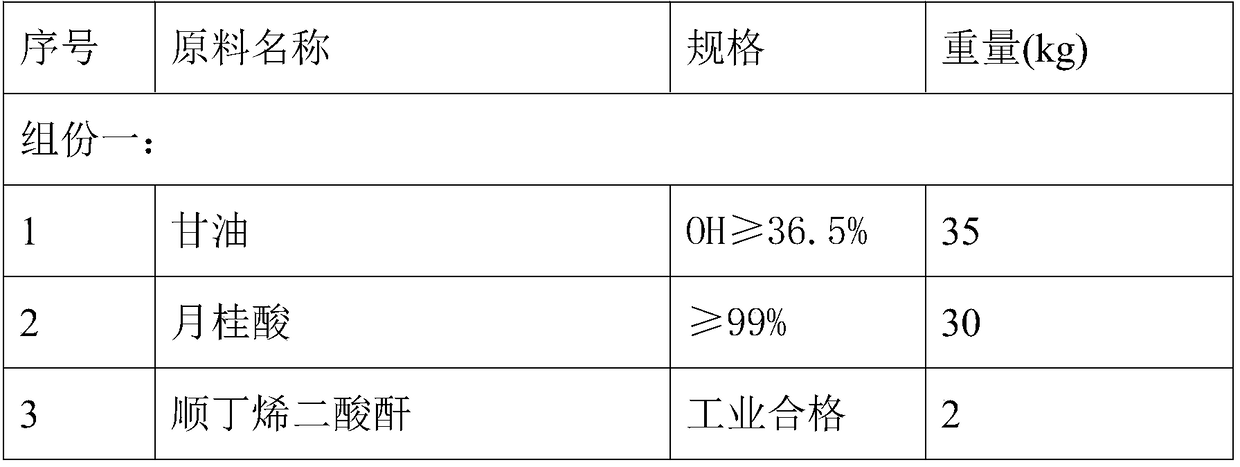

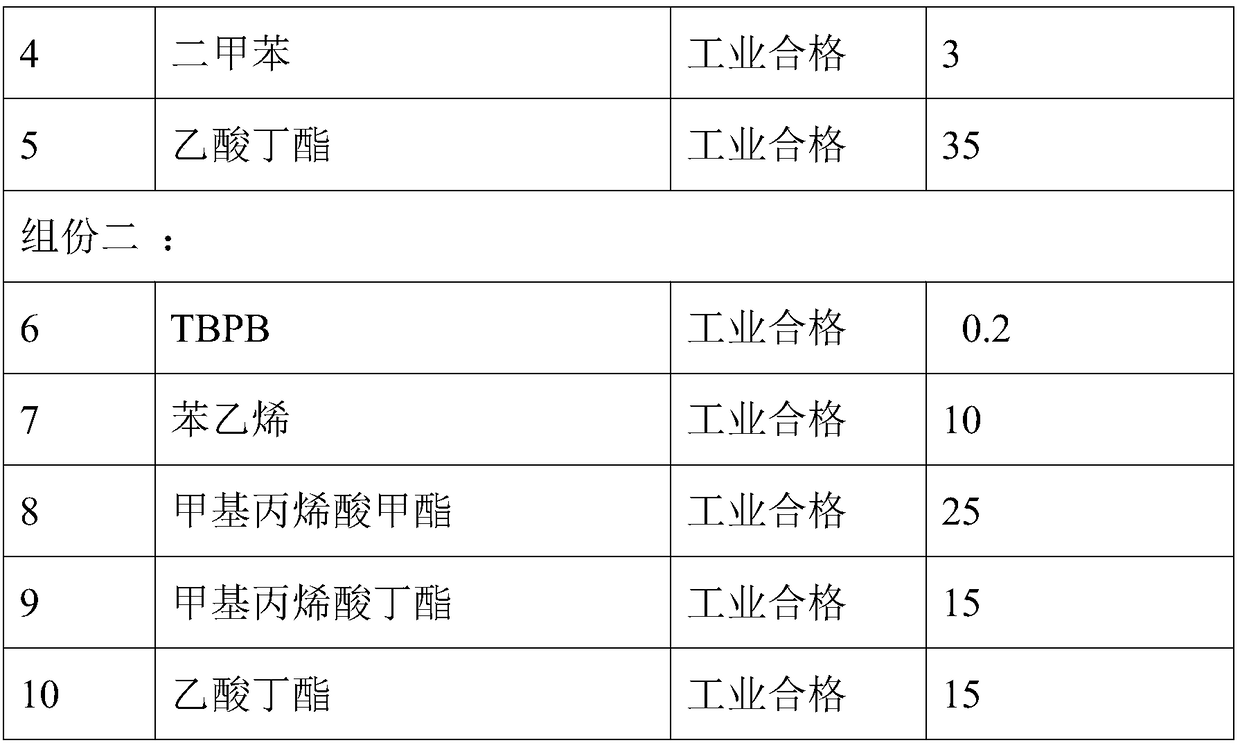

[0027] A weather-resistant and anti-corrosion resin for improving the crosslinking density of the coating film, including component one and component two; the specific weight parts are shown in the following table:

[0028]

[0029]

[0030] The preparation method of the weather-resistant and anti-corrosion resin for improving the cross-linking density of the coating film, the steps include:

[0031] (1) Put glycerin, lauric acid, maleic anhydride, and xylene in component 1 into the reaction kettle according to the formula amount, raise the temperature to 190°C and keep the acid value ≤ 10mgKOH / g, then cool down to below 100°C and put into Butyl acetate obtains base resin for subsequent use;

[0032] (2) Take out half of the amount of TBPB in component 2 according to the formula amount, and add styrene, methyl methacrylate, and butyl methacrylate into the dripping kettle, stir evenly to obtain mixed monomers for later use, and the stirring speed 80r / min;

[0033] (3) R...

Embodiment 2

[0035] A weather-resistant and anti-corrosion resin for improving the crosslinking density of the coating film, including component one and component two; the specific weight parts are shown in the following table:

[0036]

[0037]

[0038] The preparation method of the weather-resistant and anti-corrosion resin for improving the cross-linking density of the coating film, the steps include:

[0039] (1) Put glycerin, lauric acid, maleic anhydride, and xylene in component 1 into the reaction kettle according to the formula amount, raise the temperature to 200°C and keep the acid value ≤ 10mgKOH / g, then cool down to below 100°C and put in Butyl acetate obtains base resin for subsequent use;

[0040] (2) Take out half of the amount of TBPB in component 2 according to the formula amount, and add styrene, methyl methacrylate, and butyl methacrylate into the dripping kettle, stir evenly to obtain mixed monomers for later use, and the stirring speed 90r / min;

[0041] (3) Rai...

Embodiment 3

[0043] A weather-resistant and anti-corrosion resin for improving the crosslinking density of the coating film, including component one and component two; the specific weight parts are shown in the following table:

[0044]

[0045] The preparation method of the weather-resistant and anti-corrosion resin for improving the cross-linking density of the coating film, the steps include:

[0046] (1) Put glycerin, lauric acid, maleic anhydride, and xylene in component 1 into the reaction kettle according to the formula amount, raise the temperature to 210°C and keep the acid value ≤ 10mgKOH / g, then cool down to below 100°C and put into Butyl acetate obtains base resin for subsequent use;

[0047] (2) Take out half of the amount of TBPB in component 2 according to the formula amount, and add styrene, methyl methacrylate, and butyl methacrylate into the dripping kettle, stir evenly to obtain mixed monomers for later use, and the stirring speed 100r / min;

[0048] (3) Raise the te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com