Lignin-phenol-urea-formaldehyde co-condensation resin adhesive and preparation method

A technology of copolycondensation resin and lignin, applied in the direction of aldehyde/ketone condensation polymer adhesives, adhesives, adhesive types, etc. The effect of stability, wide scope of application, and potential of large commercial chemical industry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

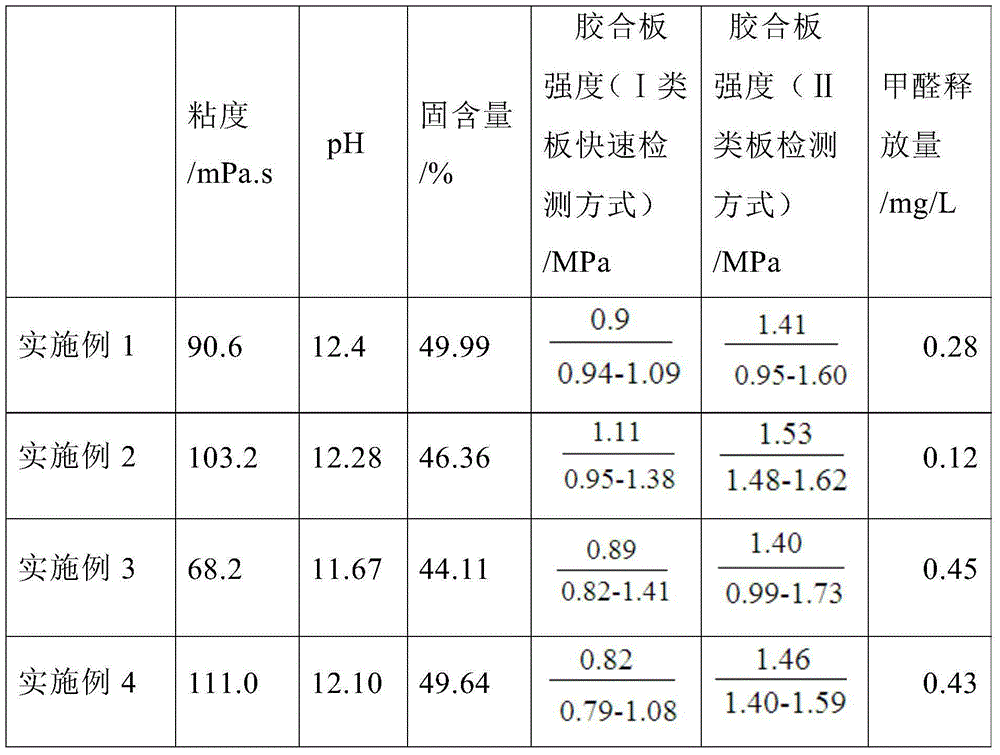

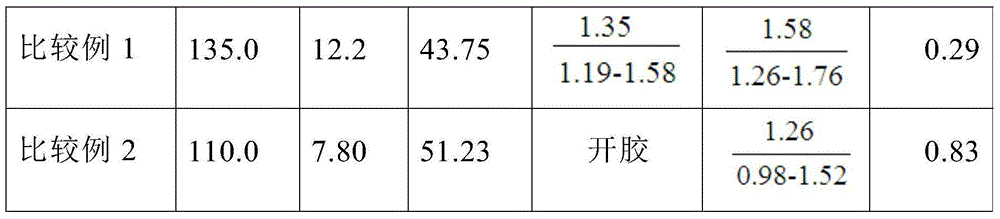

Examples

preparation example Construction

[0036] This preparation method mainly comprises the following steps:

[0037] Step 1: Mix the first batch of urea with the first batch of formaldehyde solution, add a pH regulator to the mixture, make the mixture react under the first basic condition and the first temperature, and obtain the first-stage reaction product.

[0038] Wherein, the first batch of formaldehyde solution is preferably a formaldehyde solution with a mass concentration of 37%. The pH regulator preferably uses 10% sodium hydroxide solution; under the first alkaline condition, it means that the pH value of the mixture is 7.5-8.0; the range of the first temperature is 80-85°C, preferably 80°C; the first batch The reaction time of urea and the first batch of formaldehyde solution at the first temperature is 0.5-1.5h, preferably 1h.

[0039]Step 2: Add a pH adjuster to the first-stage reaction product, adjust the pH of the first-stage product to 10.5-11.5, then add lignin, react at a second temperature, and ...

Embodiment 1

[0056] (1) Add 30g of the first batch of urea and 81g of the first batch of formaldehyde solution to the reaction vessel to form a reaction system, heat the reaction system to 80°C, and use a 10% NaOH solution to make the pH of the reaction system Keep the temperature at 7.5-8.0 and keep it warm for 1 hour to obtain the reaction product of the first stage.

[0057] (2) Use 10% NaOH solution to quickly adjust the pH of the system to 11, add 47g of corncob alkali lignin to the first-stage reaction product in step (1), and continue to react at 80°C for 0.5h. During this period, 33.07 g of the first batch of 30wt% NaOH solution was added dropwise at an appropriate speed to obtain the second-stage reaction product.

[0058] (3) Add 47g of phenol and 40.5g of formaldehyde solution in the second step to the second-stage reaction product obtained in the previous step, and react at 80°C for 0.5h, during which the second batch of 30wt% NaOH is added dropwise at an appropriate speed The...

Embodiment 2

[0063] (1) Add 30g of the first batch of urea and 81g of the first batch of formaldehyde solution to the reaction vessel to form a reaction system, heat the reaction system to 80°C, and use a 10% NaOH solution to make the pH of the reaction system Keep at 7.5-8.0, keep warm for 1 hour, and obtain the first-stage reaction product.

[0064] (2) Use a 10% NaOH solution to quickly adjust the pH of the reaction system to 11, and add 47g of corncob alkali lignin to the first-stage reaction product, and continue to react at 85°C for 0.5h, during which time, at an appropriate speed The first batch of 30wt% NaOH solution 33.07g was added dropwise to obtain the second stage reaction product.

[0065] (3) Add 47g of phenol and 40.5g of the second batch of formaldehyde solution to the second-stage reaction product, and react at 85°C for 0.5h, during which the second batch of 30wt% NaOH solution 16.53g is added dropwise at an appropriate speed to obtain the second batch of Three-stage rea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com