Stirring device of smart domestic oil press

An oil press, household technology, applied in the production of fat oil/fat, fat production, etc., can solve the problems of uneven mixing of materials, damage to the manpower by the mixing device, and increase production costs, so as to achieve uniform mixing of materials and prevent manual injury. , the effect of saving production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

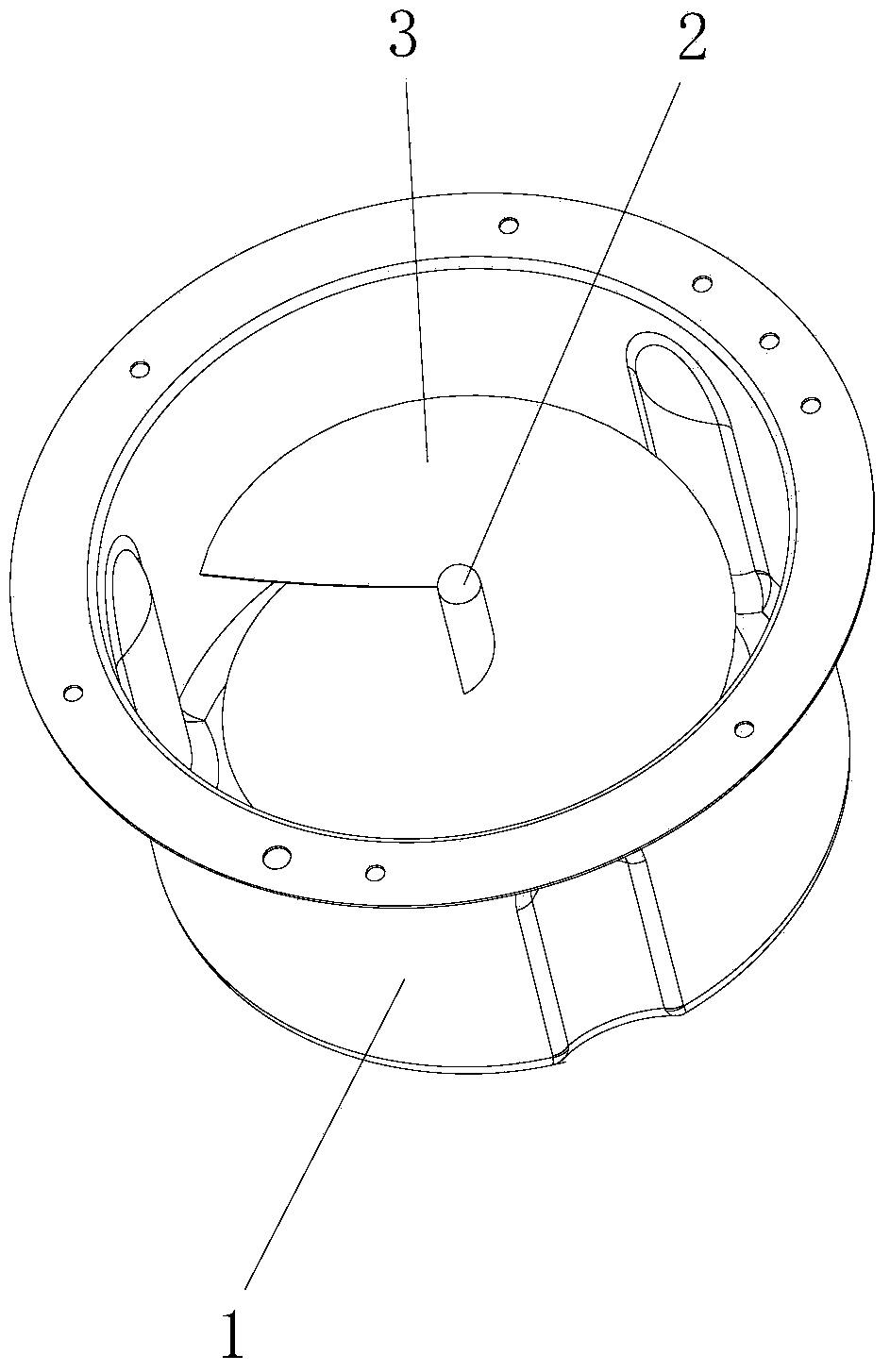

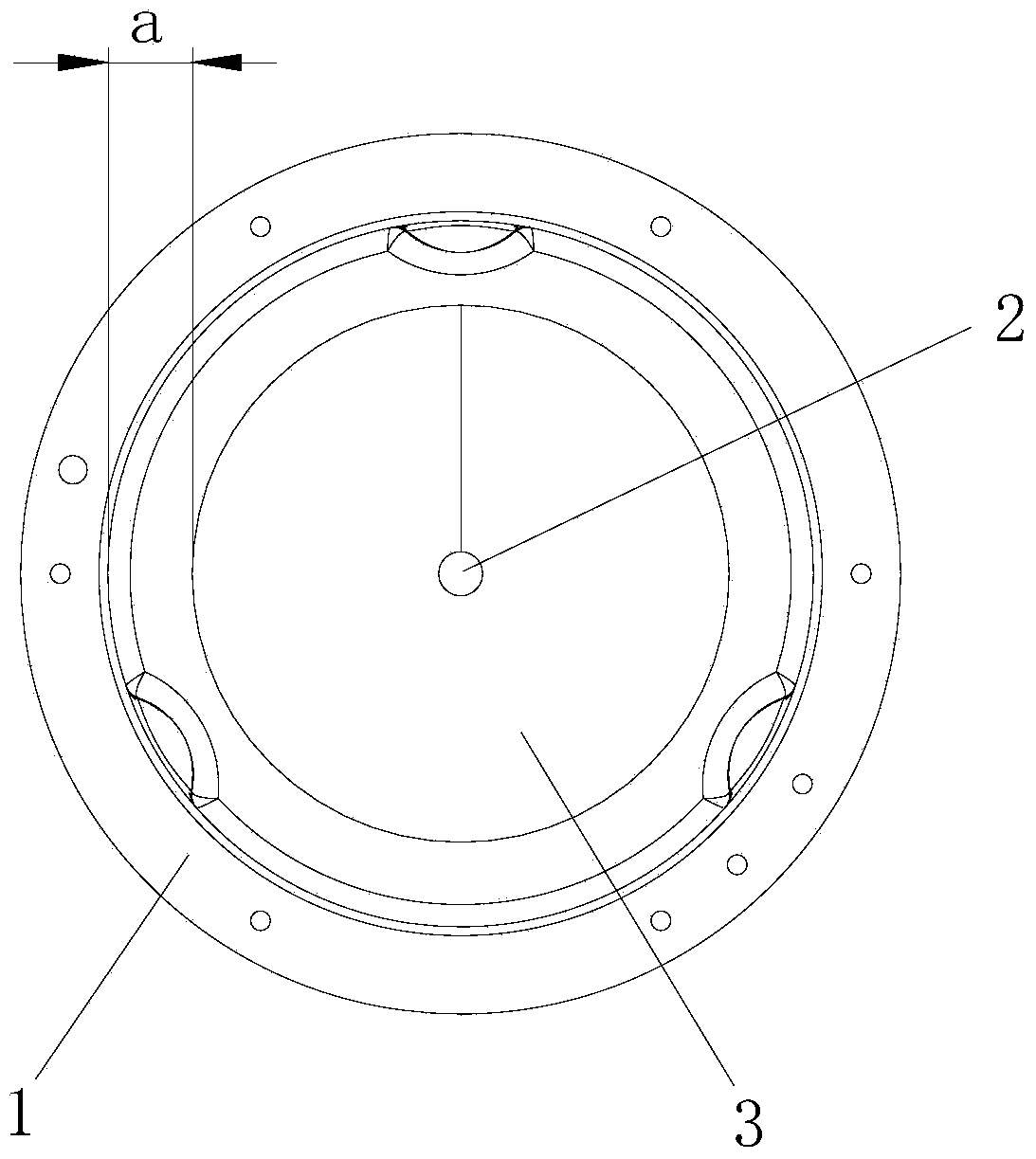

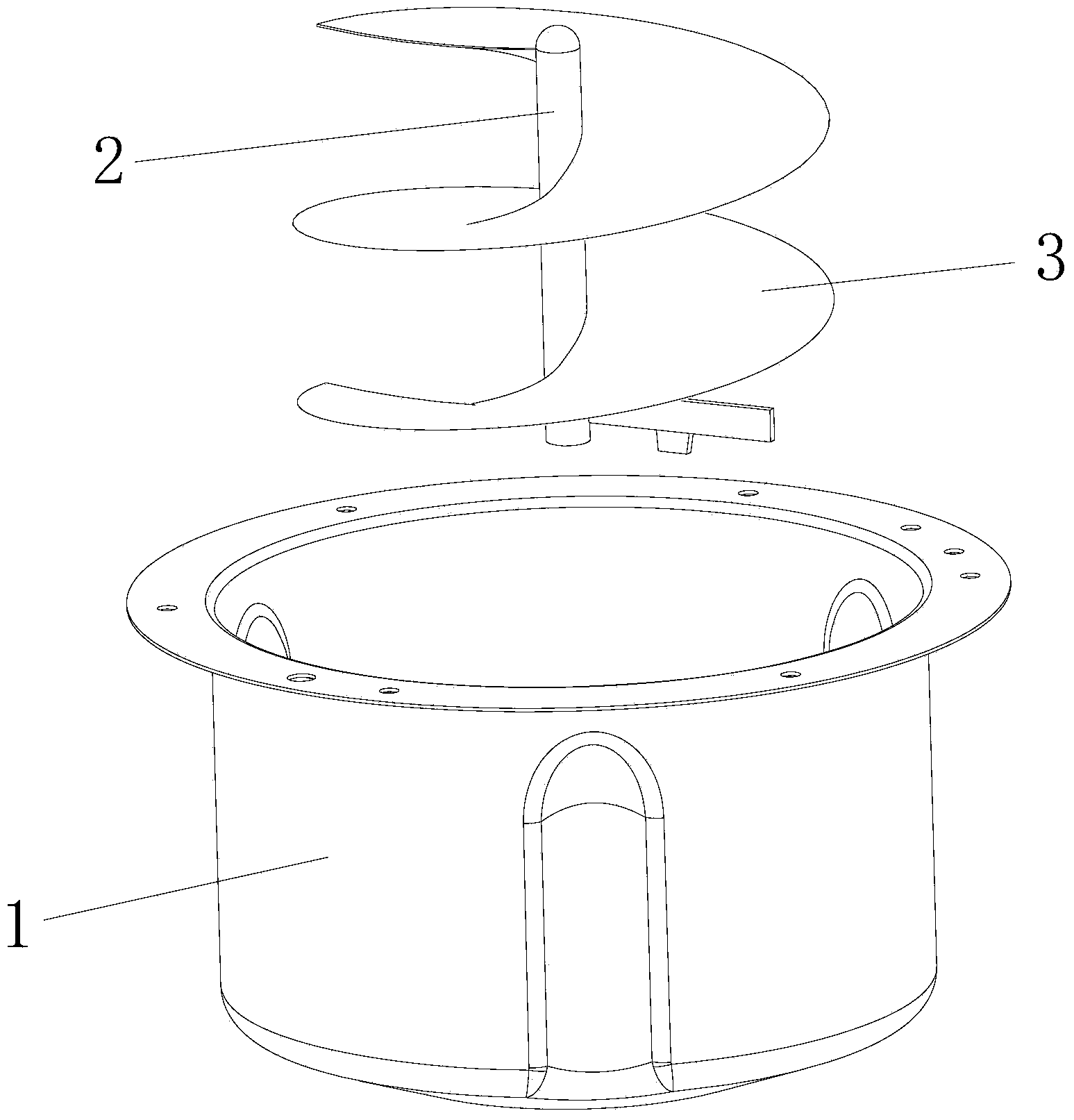

[0030] Please refer to Figure 1-8 , is embodiment 1 of the present invention, and the stir-frying device of the intelligent household oil press of this embodiment comprises a frying pan 1, and the center of the frying pan 1 is vertically installed with a rotating shaft 2, and the rotating shaft 2 can be controlled by the intelligent household oil pressing machine The motor, etc. drives the rotation. Wherein, the outer side of the rotating shaft 2 is provided with a spiral stirring member 3 for stirring materials, and the spiral stirring member 3 is located in the wok 1 .

[0031] Specifically, the helical stirring member 3 in this embodiment is a continuous helical curved surface, that is, the helical curved surface is helical around the rotating shaft 2 . Of course, the spiral curved surface can be integrally formed on the outside of the rotating shaft 2, and the spiral curved surface can also be fixed on the outside of the rotating shaft 2 by welding or other means, so tha...

Embodiment 2

[0037] Please refer to Figure 9 , is Embodiment 2 of the present invention, and the difference between this embodiment and Embodiment 1 is that the helical agitator 3 is composed of several helical blades 32, and the several helical blades 32 are installed and fixed on the outside of the rotating shaft 2 for helical. Of course, the spiral blade 32 of this embodiment can be integrally formed on the outside of the rotating shaft 2, and the spiral blade 32 can also be fixed on the outside of the rotating shaft 2 by welding or the like, so that the rotating shaft 2 can drive the spiral blade 32 while rotating. Rotate to turn over the material to realize the function of stir-frying.

[0038] Other structures and working principles of this embodiment are the same as those of Embodiment 1, and will not be repeated here.

Embodiment 3

[0040] Please refer to Figure 10 , which is Embodiment 3 of the present invention. The difference between this embodiment and Embodiment 1 is that the spiral agitator 3 includes several spiral blades 32 and a spiral surface 31, and the spiral surface 31 is located at the bottom of the rotating shaft 2. Several spiral blades The blade 32 is screw mounted and fixed on the top of the rotating shaft 2 . Certainly, the spiral blade 32 and the spiral curved surface 31 of this embodiment can be integrally formed on the outside of the rotating shaft 2, or can be fixed on the outside of the rotating shaft 2 by welding or other means, so that the rotating shaft 2 can drive the spiral blade while rotating. 32 and the spiral curved surface 31 rotate to turn over the material and realize the function of frying the material.

[0041] Other structures and working principles of this embodiment are the same as those of Embodiment 1, and will not be repeated here.

[0042] Of course, contrar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com