Special hoisting arrangement structure for allowing aluminum strip annealing coil to enter or exit high rack warehouse

A technology of high-bay warehouse and layout structure, applied in the field of production material transportation, can solve the problems such as the inability to store the annealing furnace storage table, the high risk factor of the workshop crane, and the impact on production and transportation, so as to facilitate centralized ventilation treatment, reduce plant cost, Easy to operate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

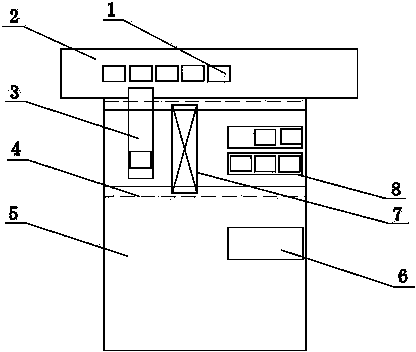

[0014] combine figure 1 , a hoisting layout structure specially used for aluminum strip annealing coils entering and exiting the high-bay warehouse, including a high-bay warehouse 2, an annealing bay 5 and an annealing furnace 6 located in the annealing bay, the high-bay warehouse 2 is arranged adjacent to the side wall of the annealing bay 5, On the side wall of the annealing span 5, there is a passage for the passage of the special material seat 3 for the elevated warehouse 2. One end of the special material seat 3 is located in the elevated warehouse 2, and the other end is located in the annealing span 5, and the other end of the special material seat 3 is connected to the The annealing volume storage platform 8 is located in the same inter-column area 4 within the annealing span 5, the inter-column area 4 is surrounded by the factory building columns supporting the annealing span 5, and a crane 7 is erected above the inter-column area 4, and the crane 7 The running direct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com