Curve drafting device

A drafting device and curve technology, applied in the field of spinning technology, can solve the problems of increasing yarn hairiness, affecting product quality, uncontrollable left and right movement of fiber bundles, etc., and achieve the effect of facilitating forward movement and reducing yarn hairiness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

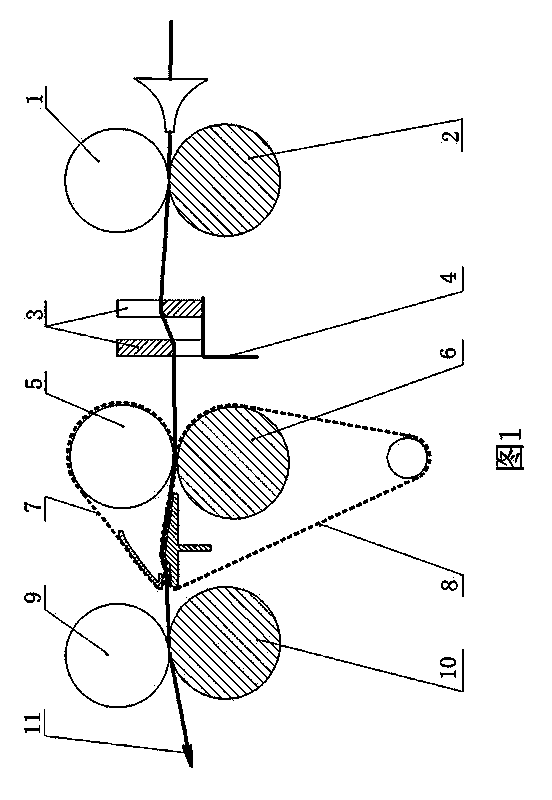

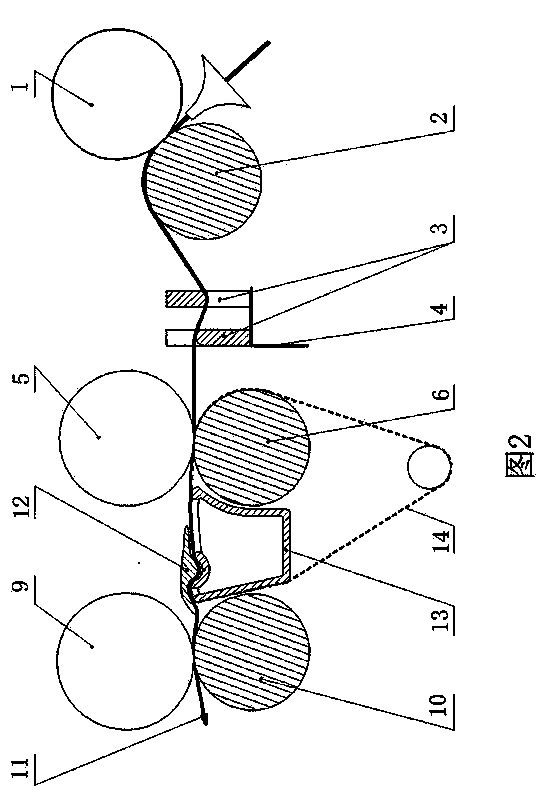

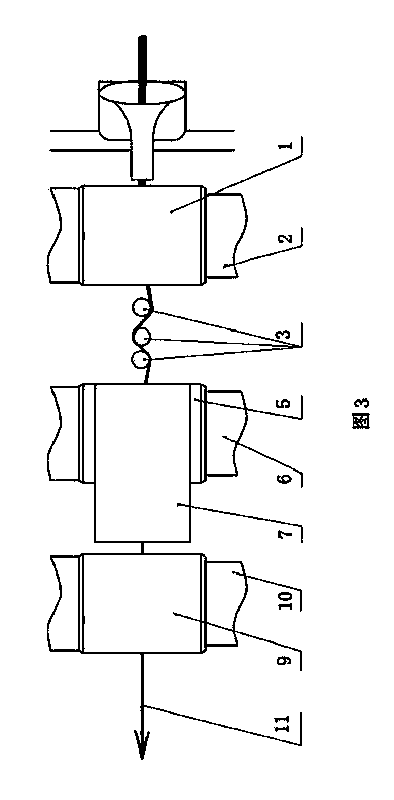

[0018] In the illustration, the surface linear speed of the rear top roller (1) and rear roller (2) < the surface linear speed of the middle top roller (5) and middle roller (6) < the surface speed of the front top roller (9) and front roller (10) The surface linear speed, the positioning body (3) is installed in the drafting area relying on the positioning body support frame (4), when the fiber bundle (11) moves forward under the action of the front traction and passes the positioning body (3), the positioning body (3 ) enables the fiber bundle (11) to pass through the drafting zone from back to front in the form of a three-dimensional curve in space, because when the fiber bundle (11) passes through the positioning body (3), the positioning body (3) can strengthen the fiber bundle (11) in the drafting zone ), which is beneficial to meet the spinning process requirements of "forward, concentrated, and stable" fiber speed change points, and improve the dryness and quality of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com