Rubbish sweeper with movable front small brush

A technology for sweeping vehicles and garbage, applied in the field of garbage sweeping vehicles, can solve the problems of low use efficiency, unclean cleaning, increased investment in manpower and material resources, etc., and achieve the effect of easy implementation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

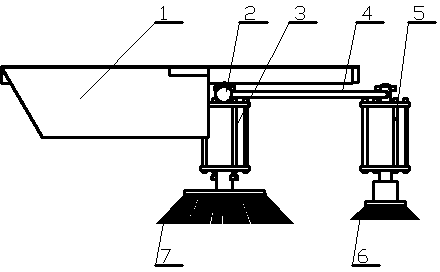

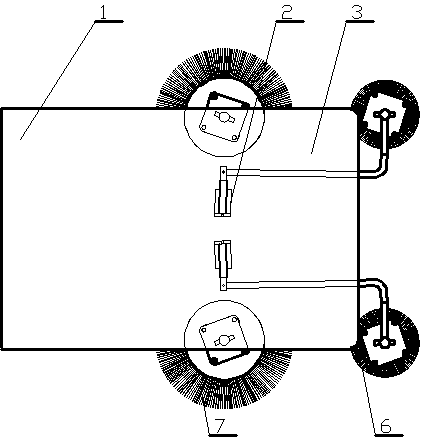

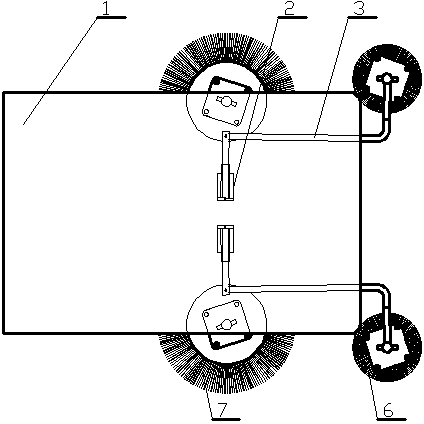

[0014] In the accompanying drawings, a garbage sweeper with a movable front small brush includes a sweeper chassis 1, a large motor 3, a small motor 5, a front small brush 6 and a front large brush 7; the front large brush 7 and the large motor The bottom end of the rotor shaft of 3 is fixedly connected to realize the rotation of the brush body. The large motor 3 is installed on the outside of the bottom of the sweeper chassis 1; The bottom end of the rotor shaft is fixedly connected to realize the rotation of the brush body; the top of the small motor 5 is fixedly connected to the end of the shorter section of the horizontal L-shaped fixed shaft 4, and the end of the longer section of the fixed shaft 4 The end is fixedly connected with the output shaft of a telescopic oil pump 2; the telescopic oil pump 2 is fixed on the bottom inner side of the sweeper chassis 1, and forms an included angle of 80-90 degrees with the fixed shaft 4 in the horizontal direction.

[0015] Further...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com