Combined sloping roof ridge tile

A sloping roof and combined technology, which is applied to roofs, roof coverings, and roofs using tiles/slate tiles, etc., can solve problems such as large roof slope range, increased maintenance costs, and damage to the safety factor of folded ridge tiles. To facilitate production, reduce production costs and procurement costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention is described in further detail by the following examples.

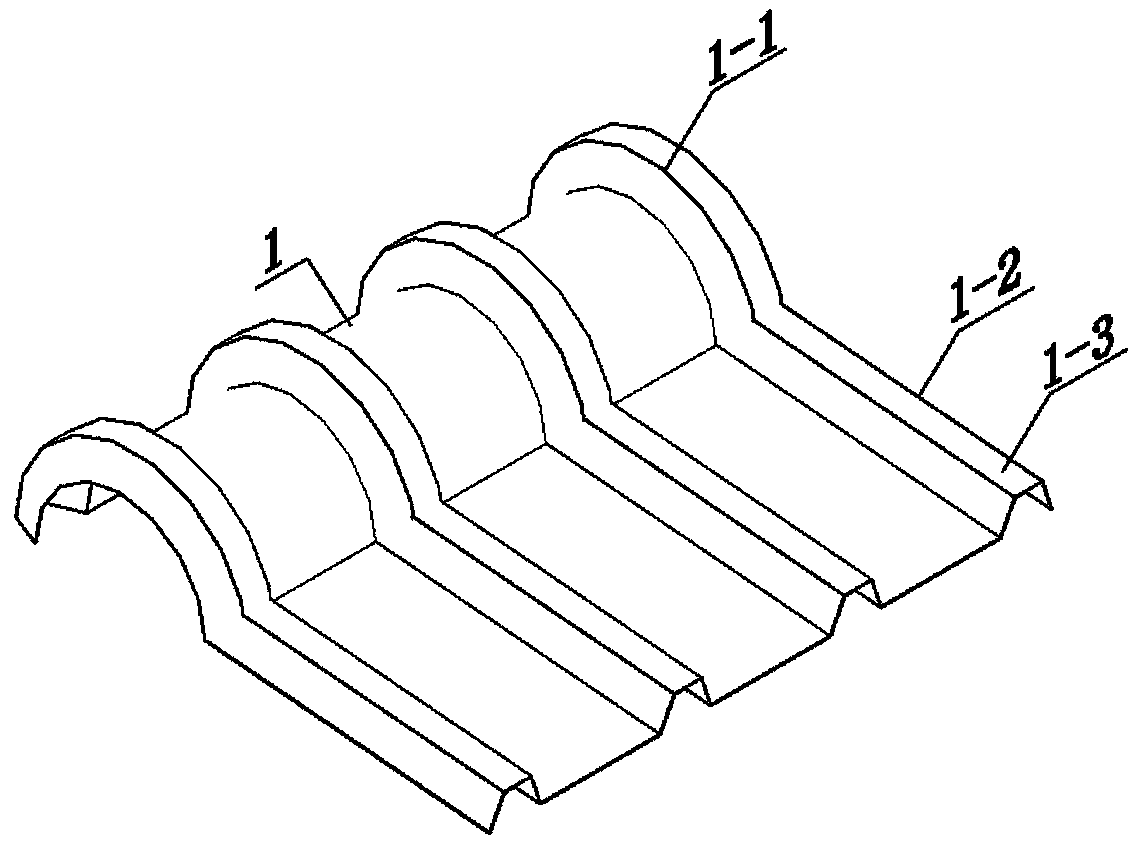

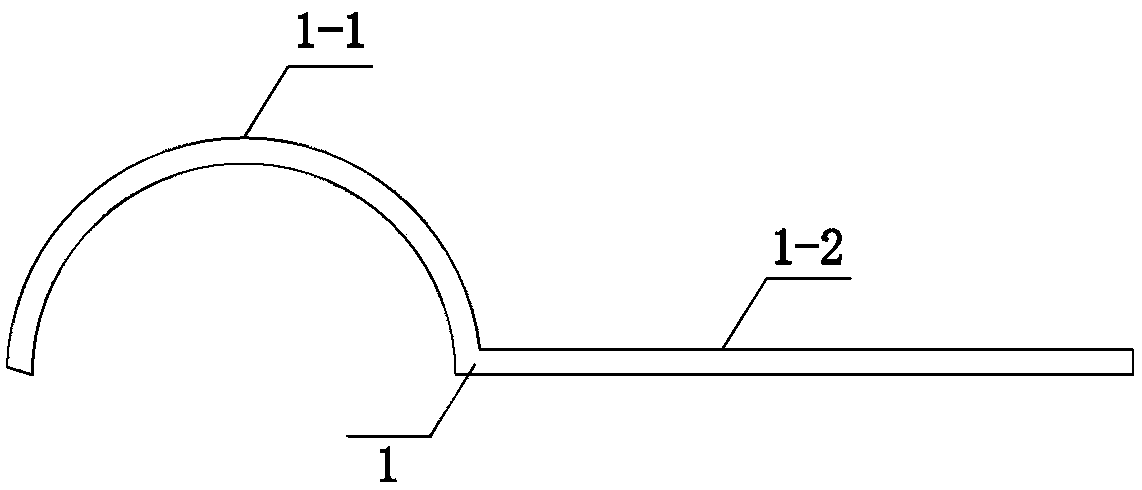

[0015] see Figure 2 ~ Figure 4 As shown, a combined slope roof ridge tile is composed of a first ridge tile 1 and a second ridge tile 2, and the first ridge tile 1 is formed by an integral mold of an arc-shaped angle adjustment part 1-1 and a plane lap part 1-2. Injection molding or flat pressing molding, the second ridge tile 2 is formed by integral mold injection molding or flat pressing of the arc-shaped angle adjustment part 2-1 and the plane overlapping part 2-2, both of which have the same structure and shape. The arc-shaped angle adjustment part 1-1 of the first ridge tile 1 and the arc-shaped angle adjustment part 2-1 of the second ridge tile 2 are freely movable and overlapped, and the plane of the first ridge tile 1 is overlapped. Part 1-2 is matched and lapped and fixedly connected with the roof tile 3 on one side of the sloping house, and the planar lap part 2-2 of the second...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com