Electrically-flushable packer and electrically-flushable insert seal for flooding well

A technology of well flushing packer and water injection well, which is applied in the directions of sealing/packing, wellbore/well components, earth-moving drilling and production, etc., can solve the problems such as the inability to realize backwashing of water injection wells and the lax closure of the backwashing valve, etc. Achieve the effect of avoiding stratified water injection failure, rapid control and monitoring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to further understand the content of the invention, features and effects of the present invention, the following embodiments are exemplified and described in detail with the accompanying drawings as follows:

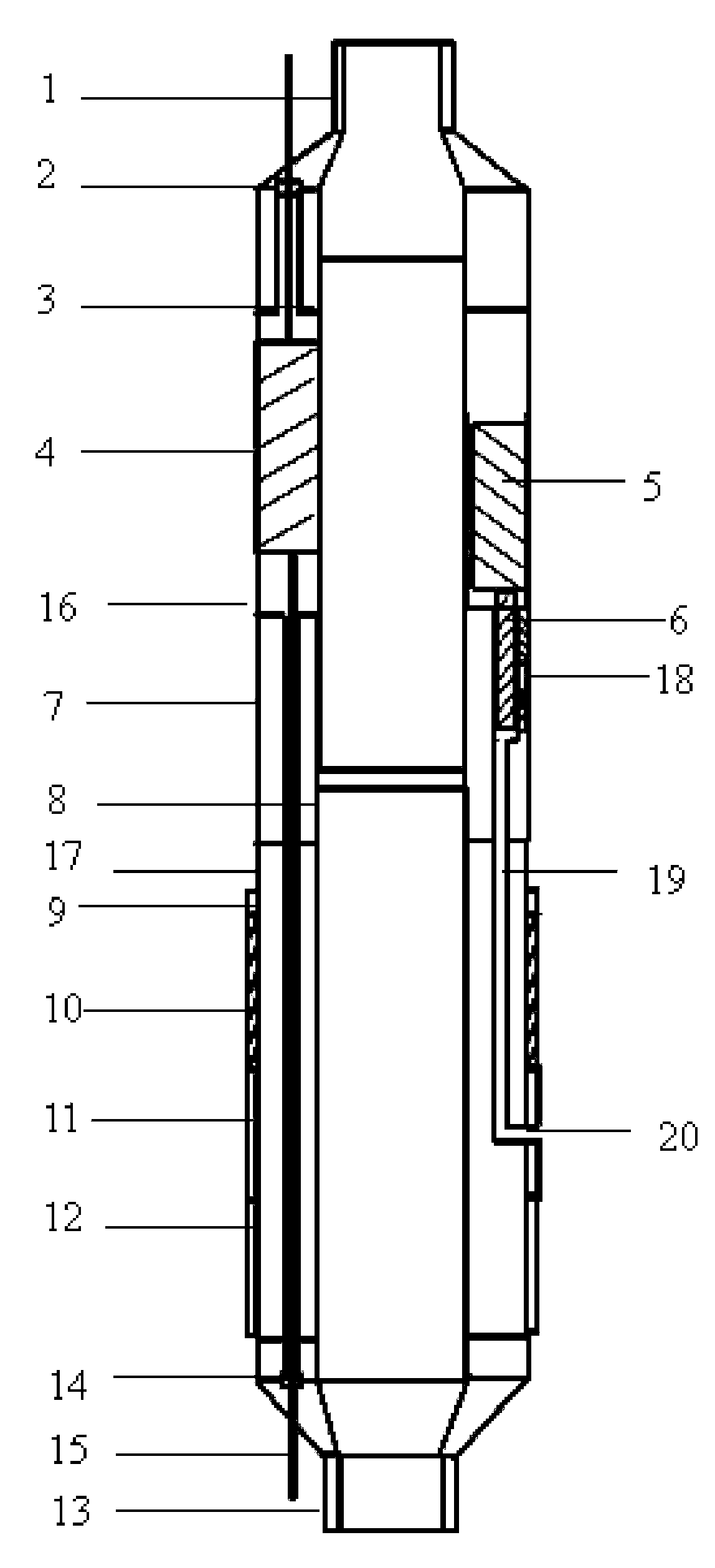

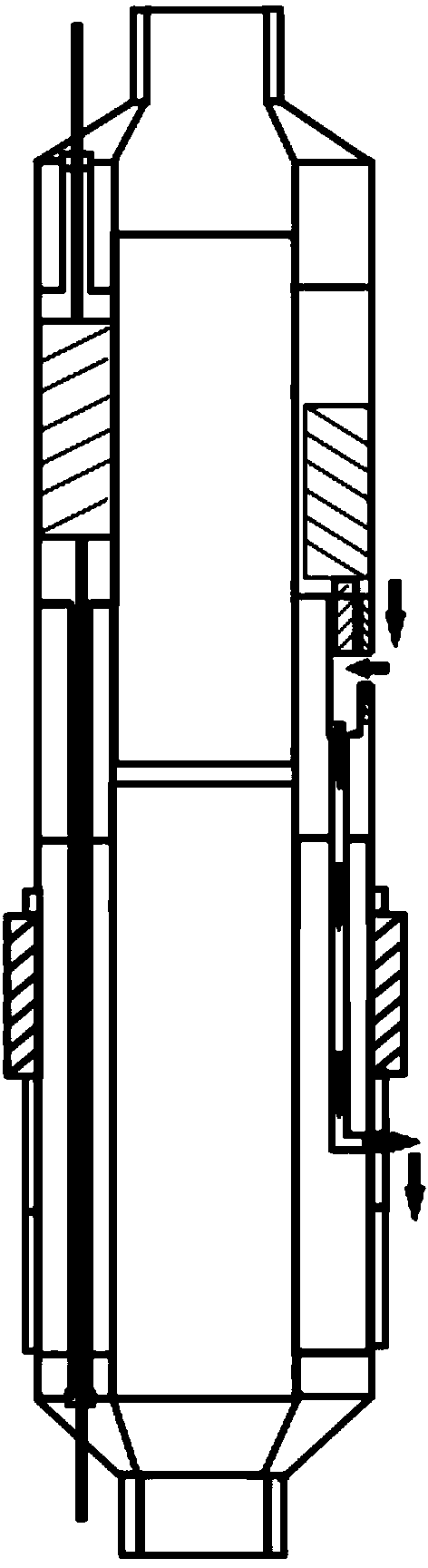

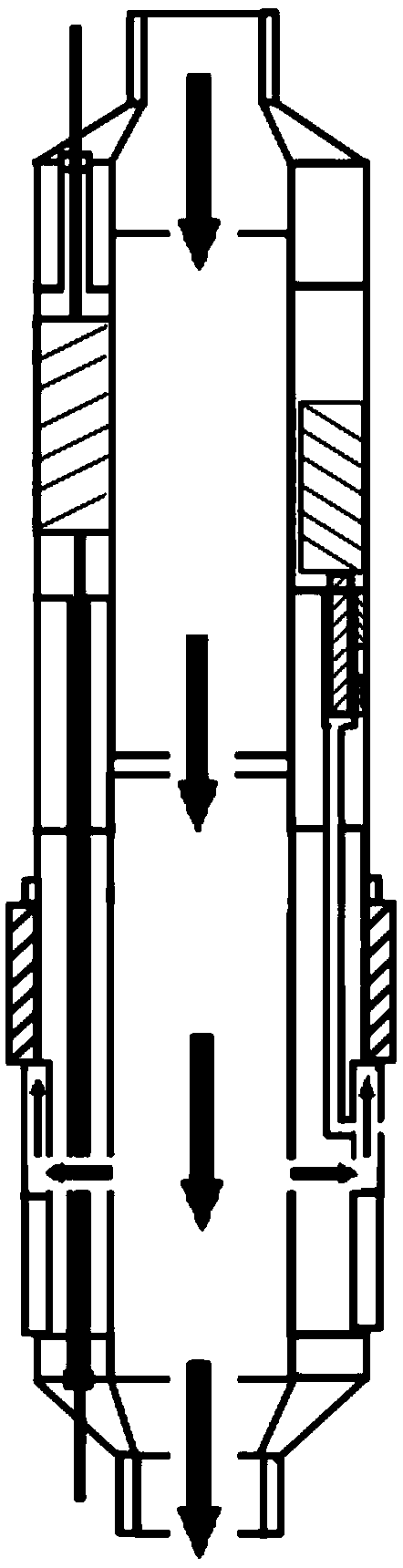

[0017] see Figure 1 to Figure 3 , an electric well-flushing packer for water injection wells, comprising an upper central pipe 3, an intermediate joint 7 and a lower central pipe 8 connected in sequence from top to bottom, the upper end of the upper central pipe 3 is connected to the upper joint 1 The lower end is internally connected, the outer lower end of the upper central pipe 3 is internally connected with the upper end of the intermediate joint 7, the lower end of the intermediate joint 7 is internally connected with the upper end of the lower central pipe 8, and the lower central pipe 8 The outside of the lower end of the intermediate joint 7 is connected with the inside of the upper end of the lower joint 13; the outside of the upper end of the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com