Pneumatic draining valve for locomotive air source system filter

A technology of filter and drain valve, which is applied in the direction of sliding valve, valve details, valve device, etc., can solve the problems of automatic drainage sticking, etc., and achieve the effect of ensuring work performance, eliminating sticking phenomenon, and eliminating long exhaust phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below through specific embodiments.

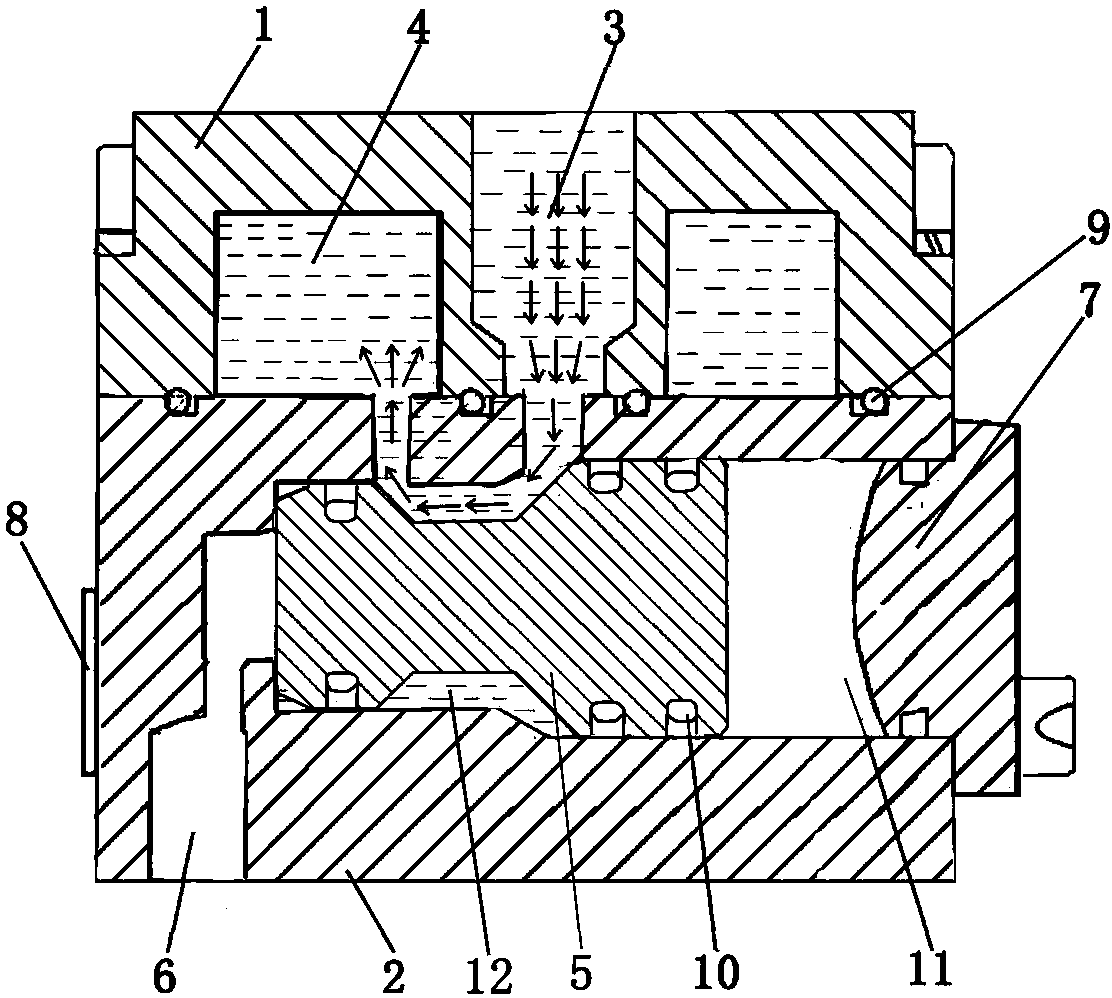

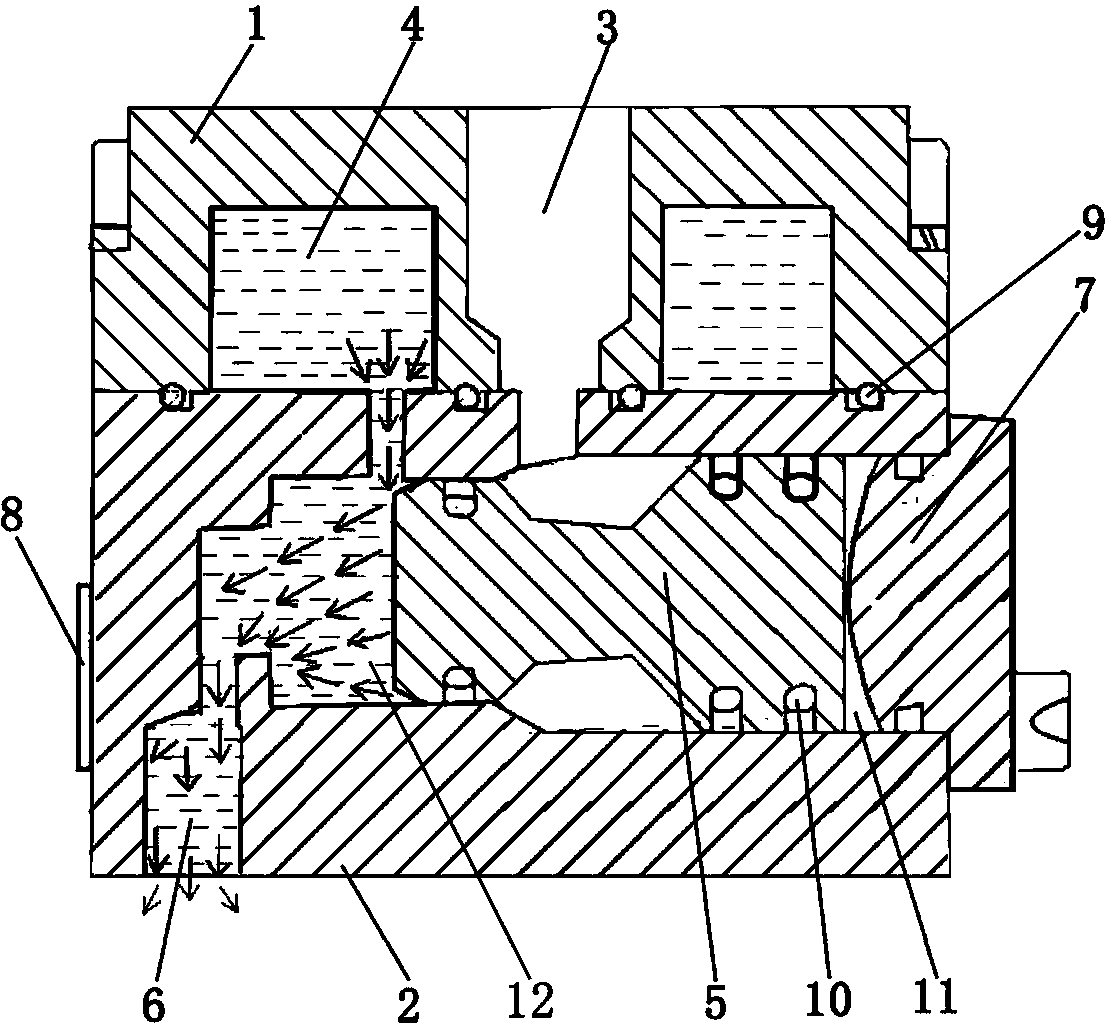

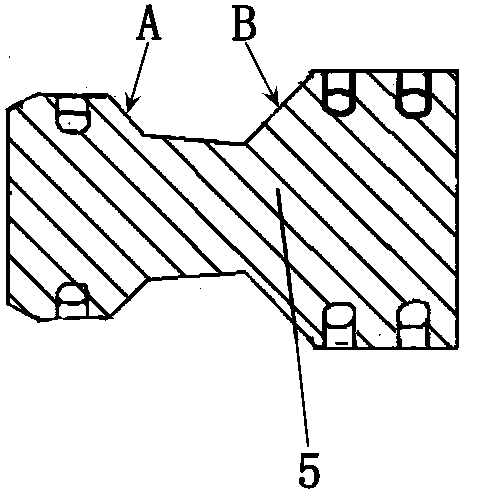

[0019] Such as figure 1 , figure 2 As shown, the main structure of the present invention is composed of an upper valve body 1 and a lower valve body 2 fixed by fastening screws and butted together, and an O-ring 9 is used between the upper valve body 1 and the lower valve body 2 Sealing; the upper valve body 1 is provided with a filter interface 3 and a dirt storage chamber 4, and the lower valve body 2 is provided with a sewage passage 6 and a piston chamber 12, and the filter interface 3, dirt storage chamber 4 and sewage passage 6 are all open In the piston cavity 12; the right end of the piston cavity 12 is closed by a closing cover 7 fixed on the lower valve body 2, and a dumbbell-shaped piston 5 is arranged in the piston cavity 12 ( image 3 As shown), a gas chamber 11 is formed between the piston 5 and the closing cover 7, and an external gas source (not shown in the figure) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com