High pressure exhaust check valve

A technology of check valve and high discharge, which is applied in the direction of valve details, control valves, valve devices, etc., to achieve the effect of safe and reliable sealing, reliable sealing and increased sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention is described in detail below in conjunction with accompanying drawing and specific embodiment:

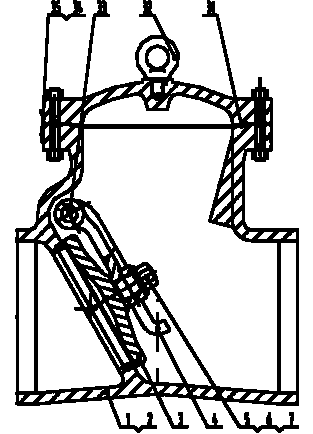

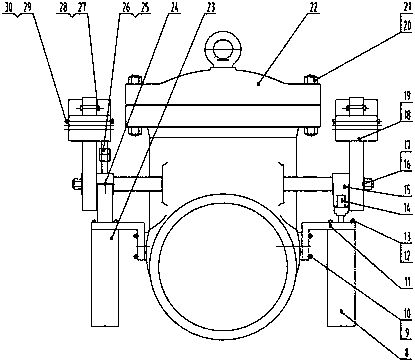

[0013] Such as figure 1 As shown, a high-row check valve includes a valve body 1. A 30° valve body seat ring hole is arranged in the valve body 1. A rocker 4 is connected to the valve body seat ring hole through a key 33. On the rocker rod 4 There is a hole, and a pin 7 is pierced in the hole. The pin 7 connects the rocker 4 and the valve disc 3 together. The pin 7 is also connected with a lock nut 5. A lock washer is placed between the lock nut 5 and the pin 7. 6. The top of the valve body 1 is fixed with a bonnet 22 by bolts 20 and nuts 21 , a gasket 31 is placed between the bonnet 22 and the valve body 1 , and the top of the bonnet 22 is also fixed with eyebolts 32 .

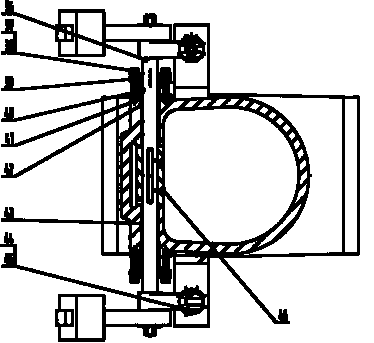

[0014] Such as image 3 As shown, one end of the shaft 36 passes through the No. 1 pneumatic actuator 8 and the pressure sleeve 39, the pressure sleeve 39 is fixed on the valve body ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com