led car headlight high beam optical module

A technology for automotive headlights and optical modules, which is applied in the field of high-beam optical modules for LED automotive headlights. It can solve the problems of heat deformation, uneven light, and fog generation of headlight parts, and improve convection heat dissipation. performance, improve heat dissipation efficiency, and increase the effect of heat dissipation area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

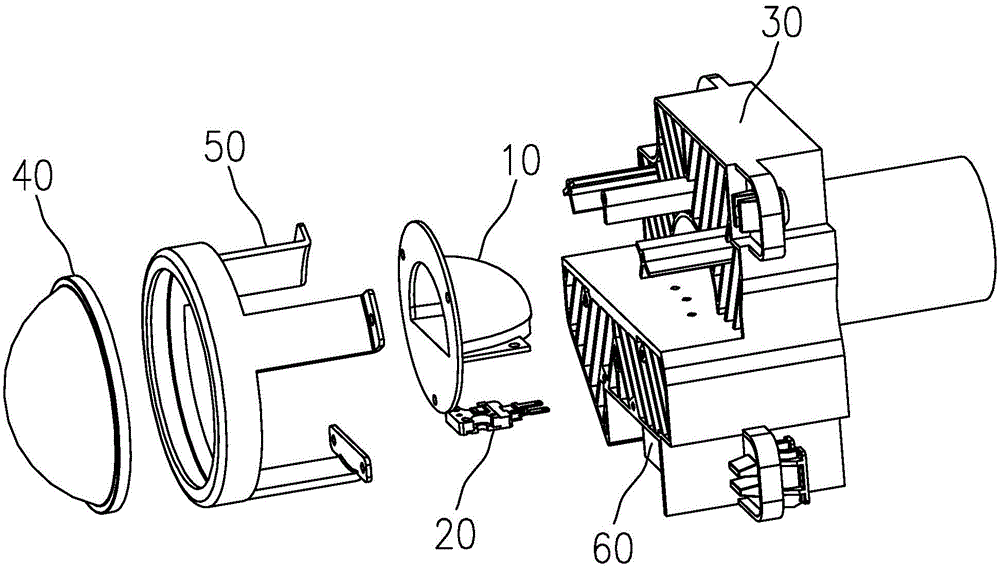

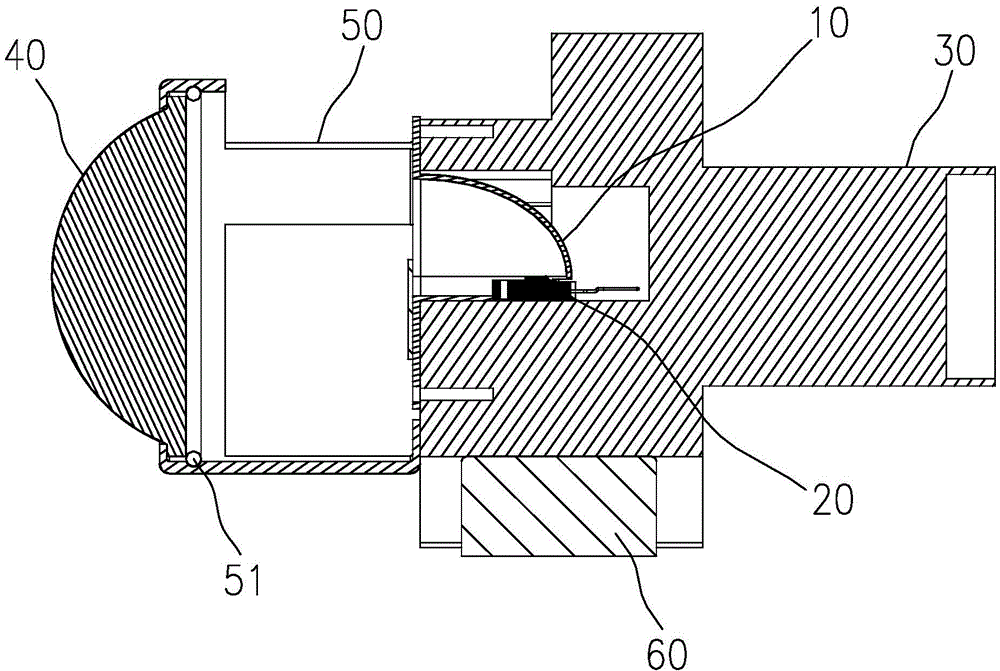

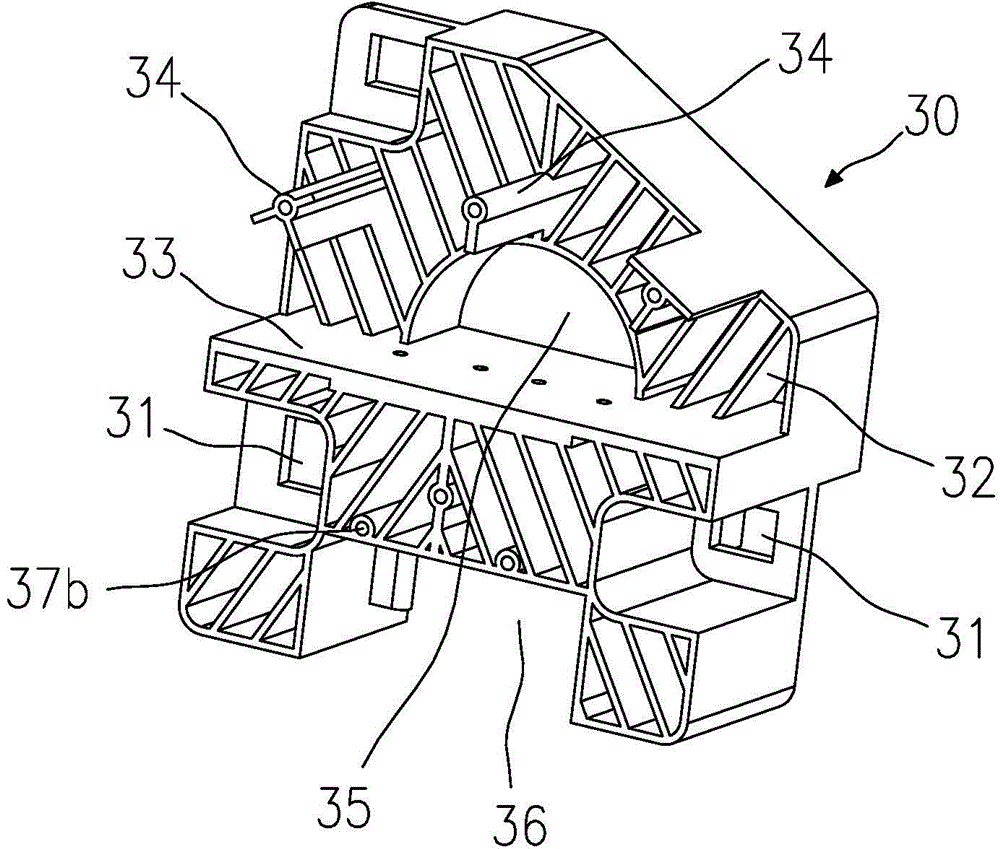

[0055] For ease of understanding, the specific structure of each component in the present invention will be further described below in conjunction with the accompanying drawings.

[0056] 1. Reflector

[0057] Such as Figure 6-8 As shown, the reflector includes a reflective cup body 10, and the reflective surface 14 of the reflective cup body 10 is in the shape of an ellipsoid. A semi-revolved surface formed by rotating 180°; the ellipse arc is an arc segment enclosed by the major axis a and the minor axis b of the ellipse in the same quadrant.

[0058] Such as Figure 6 As shown, the reflective surface 14 of the reflective cup body 10 is also the inner wall surface of the reflective cup body 10 .

[0059] In the reflector of the present invention, the length ratio between the major axis a and the minor axis b of the ellipse where the ellipse arc is located is 3:2. For example, when the major axis a of the ellipse is 90mm, the minor axis b of the ellipse The length is 60m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com