Gray-gradient-based measurement method of mottle of printed product

A technology of image grayscale and measurement method, which is applied in the direction of optical testing for flaws/defects, and can solve problems such as low precision, rough calculation methods, and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0044] Now take the printing ink spots of offset printing paper as an example to specifically illustrate the method and process of measuring ink spots of the present invention.

[0045] (1) Adjust the parameters of the scanner, and place the ink spot sample printed on the offset printing paper to collect the image correctly. The scanner parameters are set as follows: brightness is 50, source is normal, scanning mode is black and white photo, and resolution is 1200DPI.

[0046] (2) Sampling the image printed on offset printing paper, the image size is 42.7mm*42.7mm, the discrete image pixels are 2048*2048, the gray level of the image is 256, and the number of images is 70.

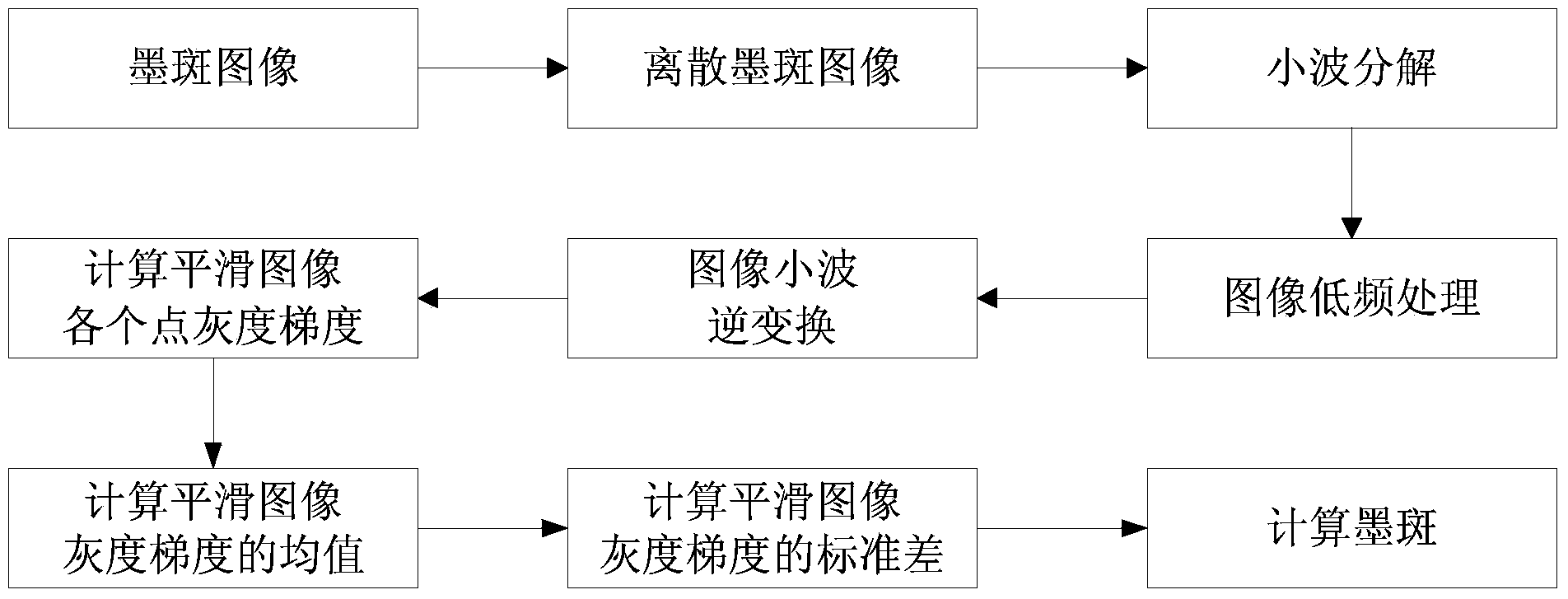

[0047](3) Perform multi-scale discrete wavelet transform on each image, use different wavelet bases to decompose different series, decompose the printed ink spot image into high-frequency image and low-frequency image, remove high-frequency noise, and retain Low-frequency images, and obtain the low-frequen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com