Battery life measurement method based on internal resistance and voltage measurement

A measurement method, voltage measurement technology, applied in the direction of measuring electrical variables, measuring electricity, measuring resistance/reactance/impedance, etc., to improve safety and economy, intelligentize the detection and maintenance process, and reduce uncertain safety hazards Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

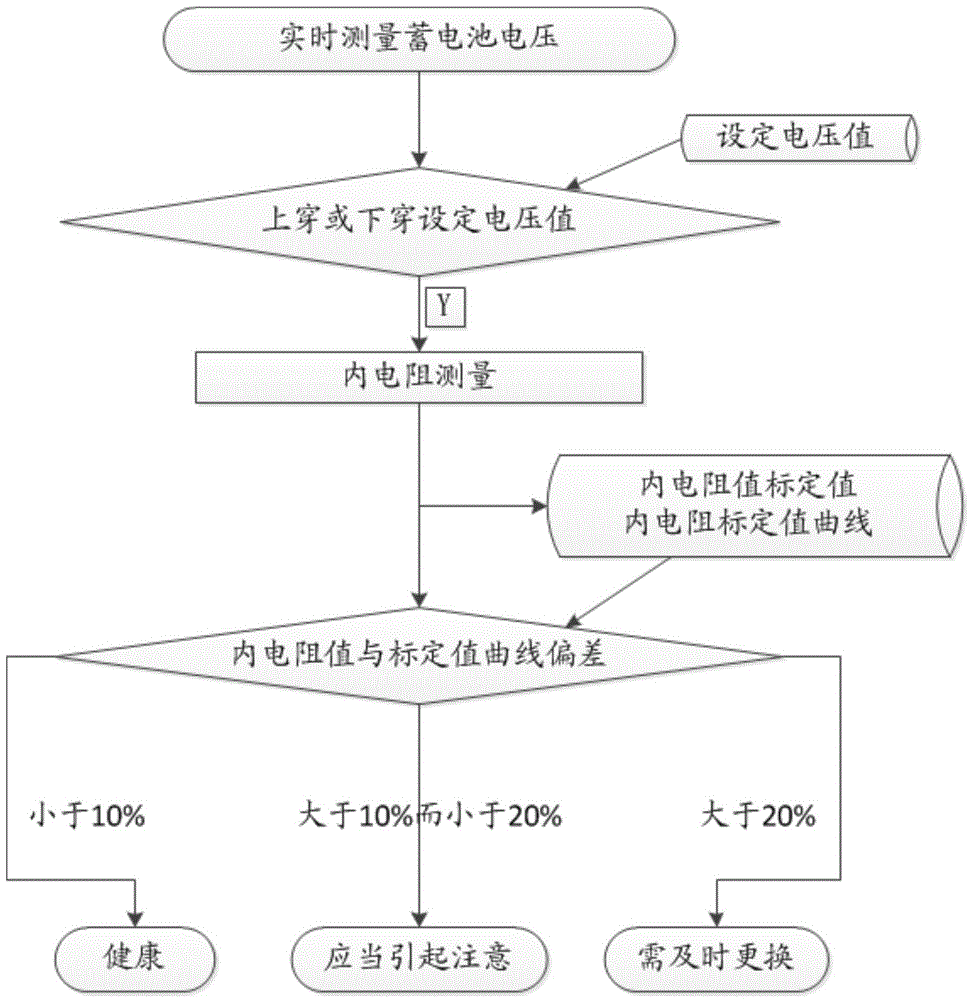

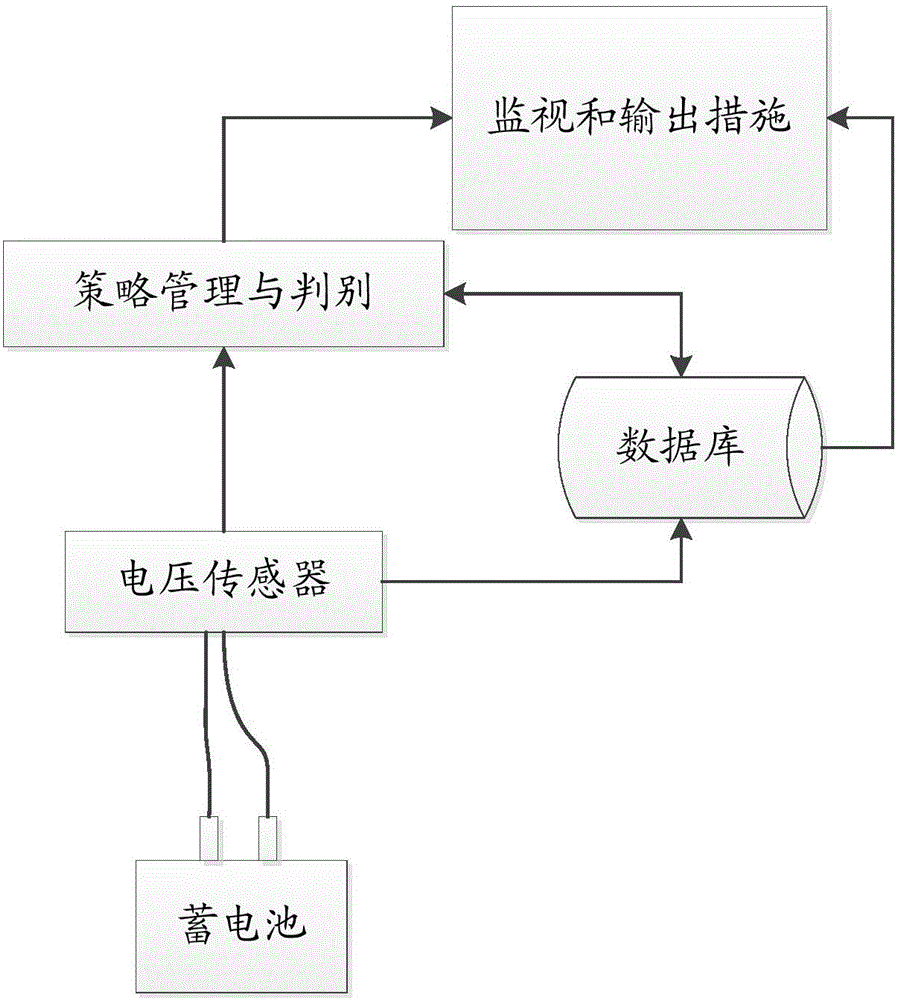

[0026] Such as figure 1 and figure 2 As shown, a battery life measurement method based on internal resistance and voltage measurement includes the following steps:

[0027] 1) Obtain the battery voltage signal through the voltage sensor;

[0028] 2) When the voltage signal reaches the set voltage value of voltage up or down, trigger the measurement of the internal resistance of the battery. The set voltage value of the above voltage is the charging process, and the set voltage value of the voltage down is the discharge process;

[0029] 3) Judging the deviation between the measured internal resistance value and the calibration value curve to determine the battery life.

[0030] The process of generating the calibration value curve is as follows:

[0031] 11) For the uncalibrated battery, set the number of internal resistance measurement times, and the average value of the internal resistance of the battery obtained under the same conditions is used as the calibration value...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com