Battery module

A battery module and battery technology, which is applied to battery components, circuits, electrical components, etc., can solve the problems that the battery cannot be connected to the conductive sheet, affects the discharge efficiency of the battery, and has a large resistance between the battery and the conductive sheet.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

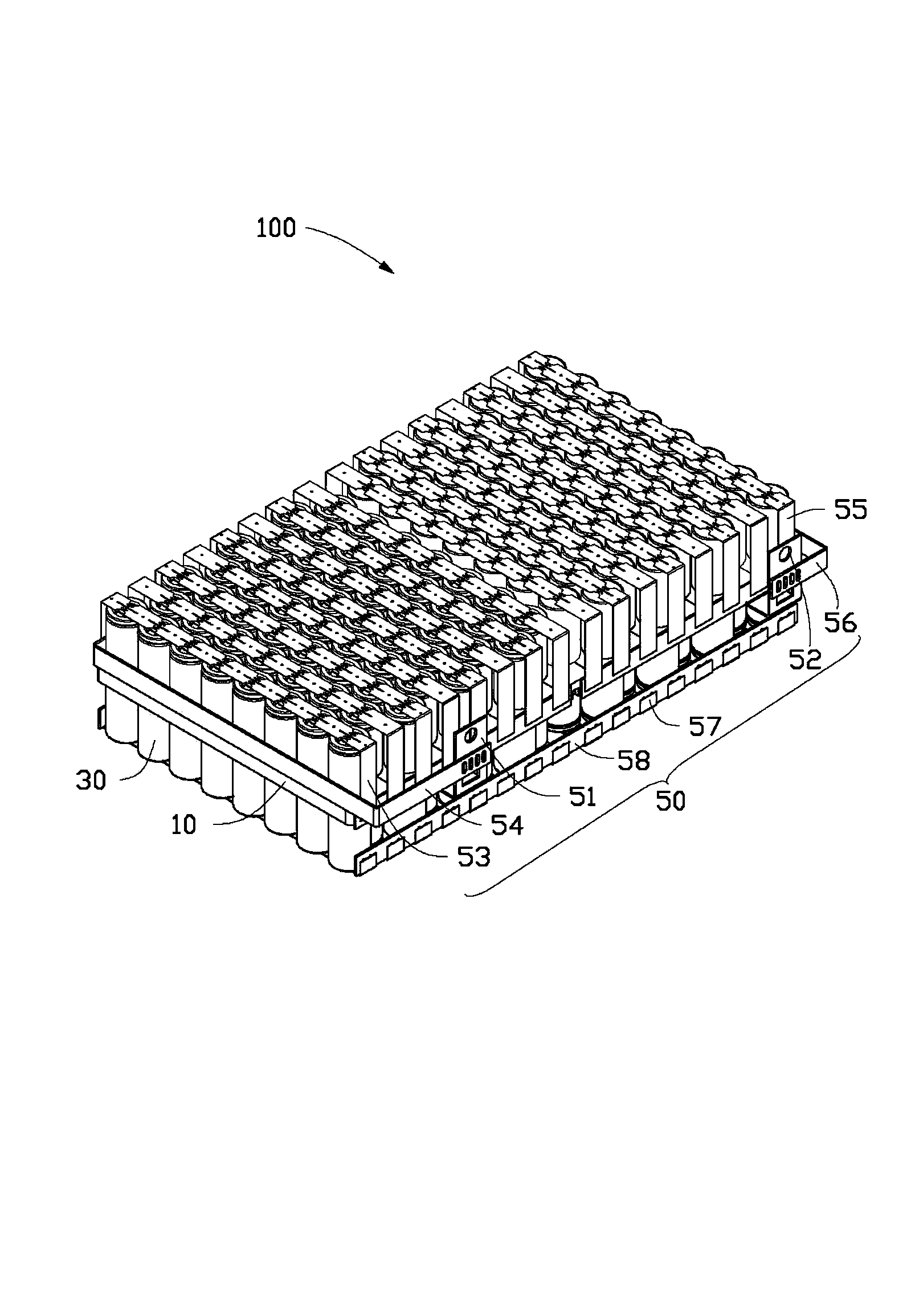

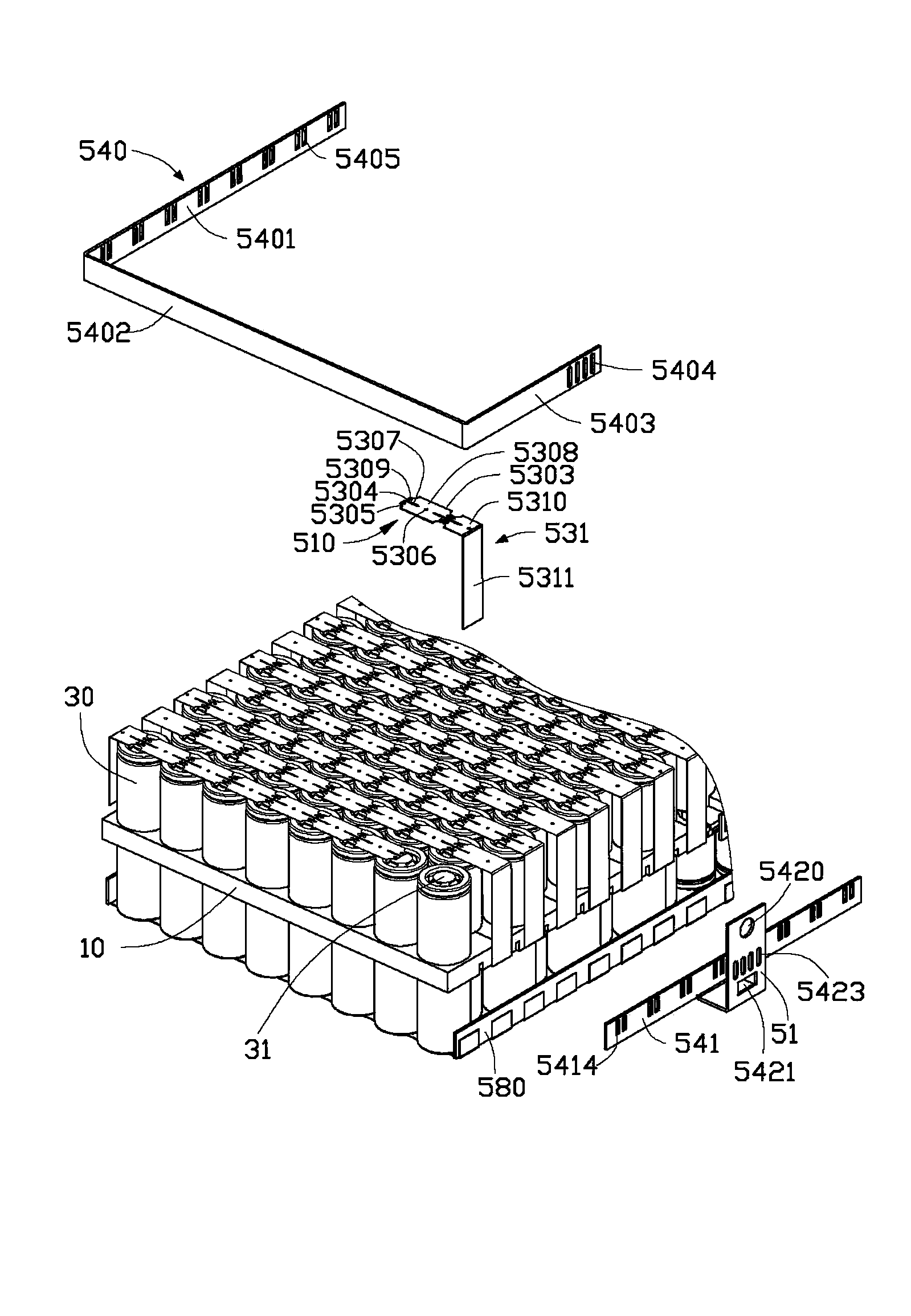

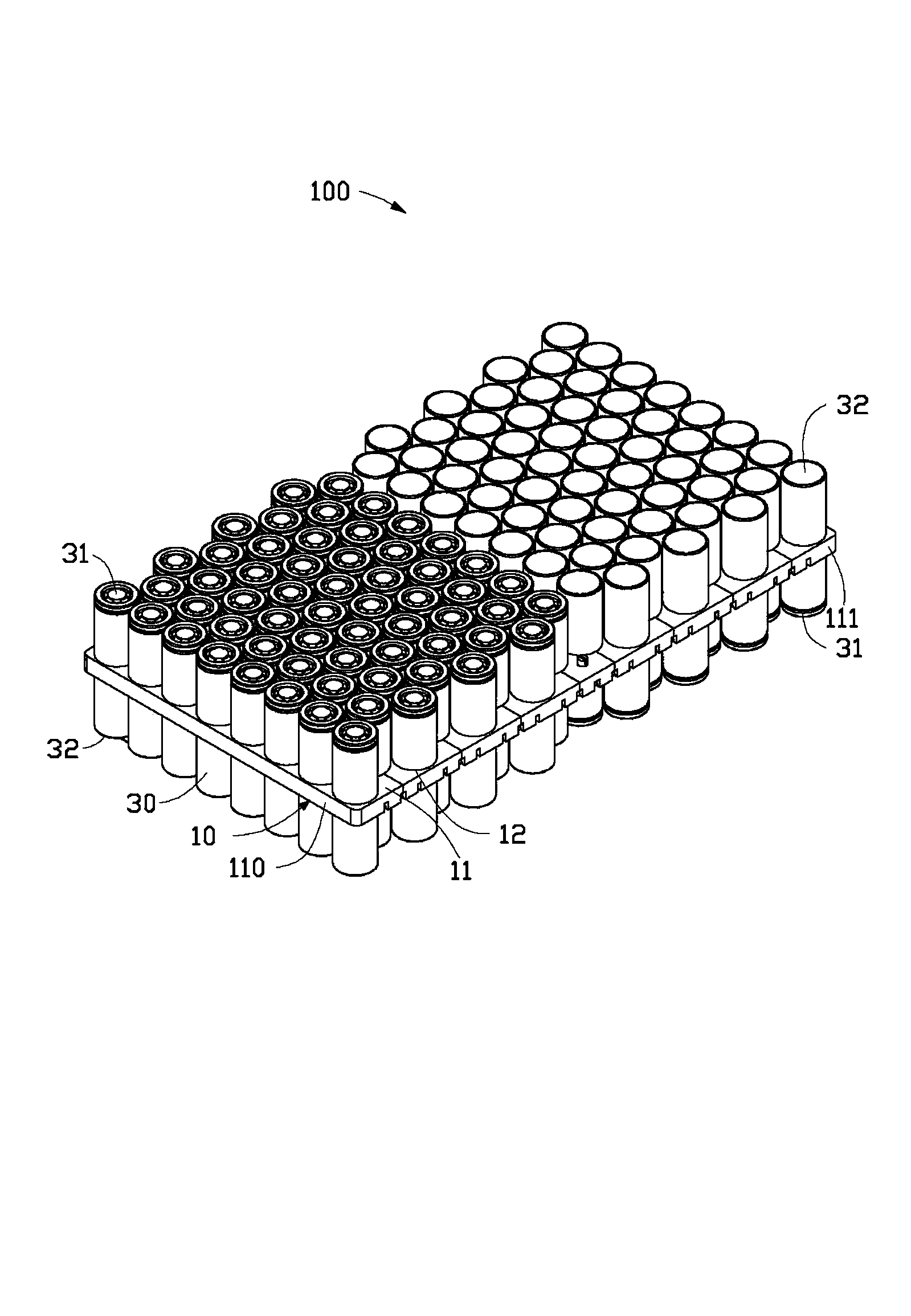

[0013] Please refer to Figure 1 to Figure 3 , the battery module 100 according to one embodiment of the present invention includes a battery holder 10 , a plurality of batteries 30 passing through the battery holder 10 , and a connection unit 50 connecting the batteries 30 together.

[0014] The battery holder 10 includes an upper surface 11 including a first end 110 and a second end 111 . The battery holder 10 also defines a plurality of rows of battery receiving holes 12 penetrating through the upper surface 11 . In this embodiment, 16 rows of battery receiving holes 12 are opened on the battery holder 10 , and are arranged at intervals of 8 or 7 in each row. Since the number of battery receiving holes 12 in two adjacent rows is different and arranged in a dislocation, the battery receiving holes 12 between different rows can be arranged more closely to save the area of the entire battery holder 10 . The battery receiving holes 12 near the first end 110 and the battery ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com