Inverter controller and method for controlling torque motor

A torque control and control circuit technology, applied in control systems, AC motor control, electrical components, etc., can solve the problems of inability to adjust according to needs, high maintenance costs of torque motors and controllers, and high energy consumption, etc., to achieve the highest speed Non-adjustable, fast response, large speed control range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The variable frequency controller and method for controlling a torque motor of the present invention will be described in detail below in conjunction with the accompanying drawings. Those skilled in the art should understand that the embodiments described below are only illustrative illustrations of the present invention, and are not intended to limit it in any way.

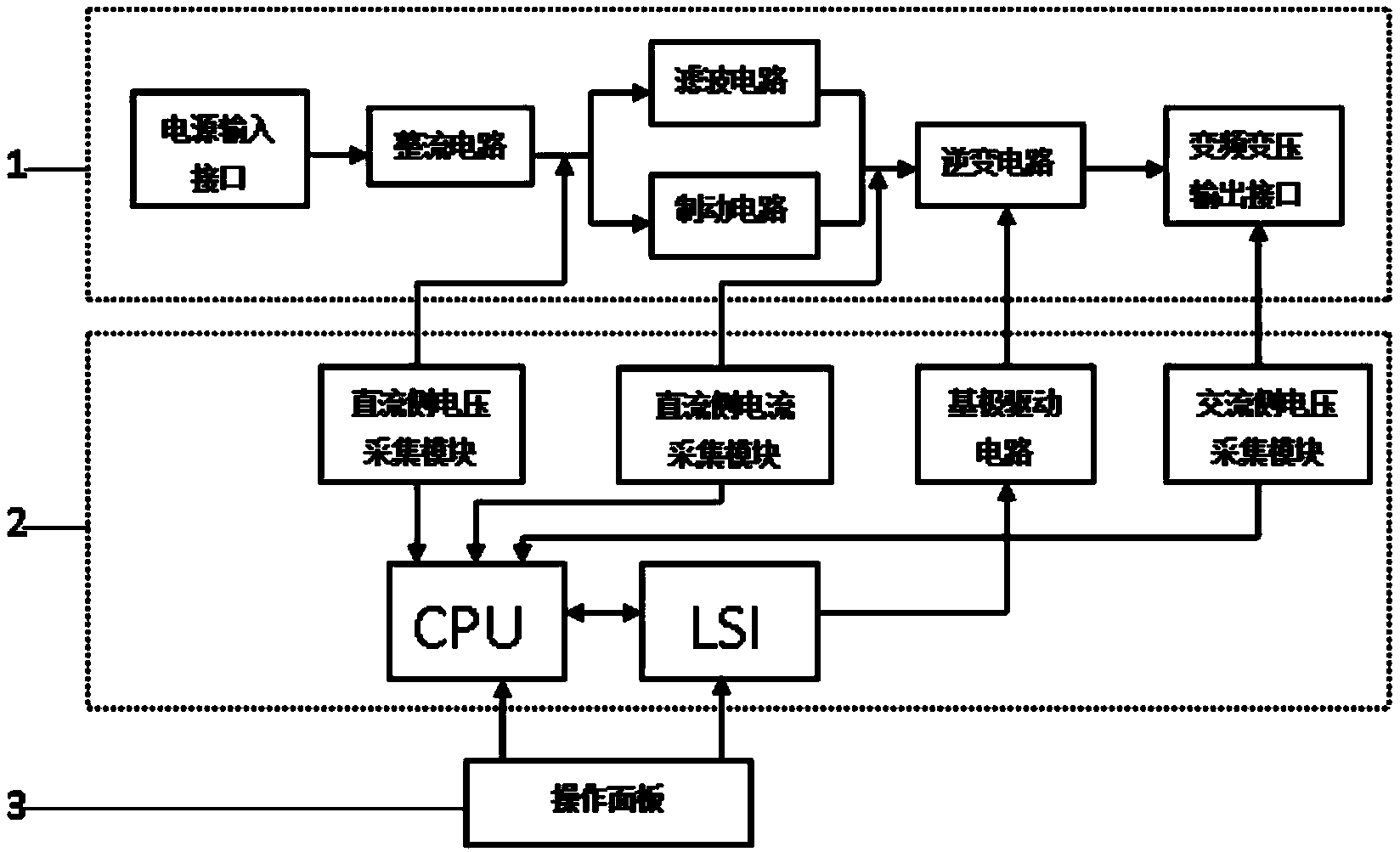

[0017] Such as figure 1 As shown, the frequency conversion controller for controlling a torque motor according to the present invention mainly includes a main circuit 1 , a control circuit 2 and an operation panel 3 . The main circuit 1 mainly includes a power input interface, a rectifier circuit, a filter circuit, a brake circuit, an inverter circuit and a variable frequency variable voltage output interface. The control circuit 2 mainly includes a central processing unit (CPU), an integrated circuit (LSI), a base drive circuit, a DC side voltage acquisition module, a DC side current acquisition module a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com