Method and processing plant for producing prefabricated elements made of mineral-bonded building materials

A technology for processing equipment and prefabricated components, which is applied in the field preparation of building components, processing of building materials, manufacturing tools, etc., can solve problems such as long construction time and long transportation distance, and achieve the effect of enhancing reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

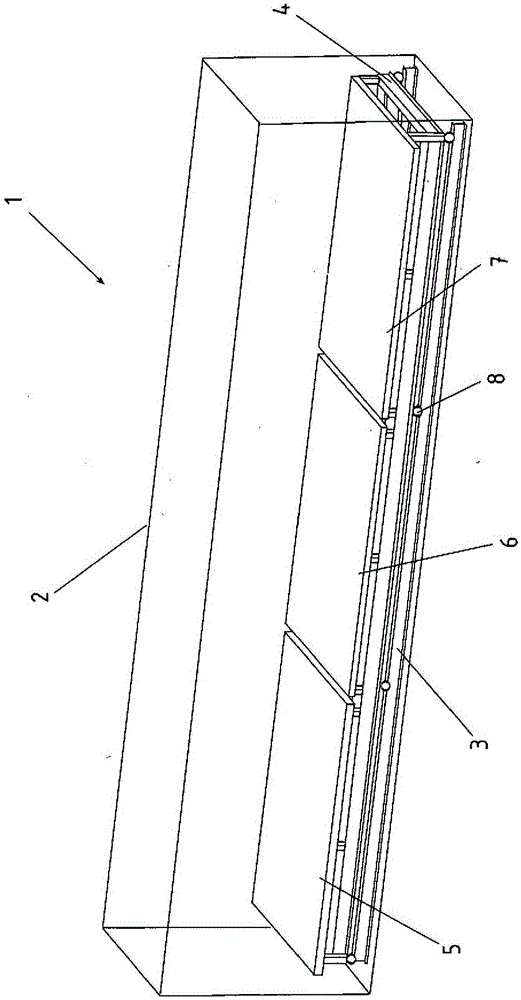

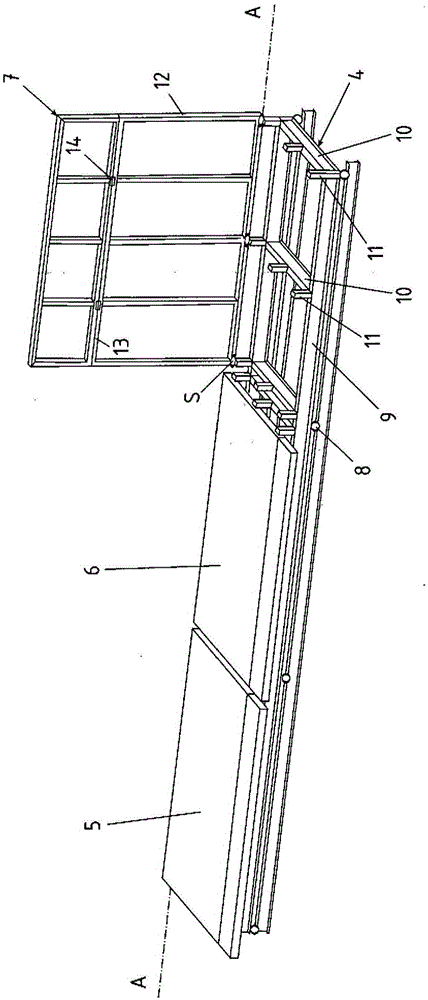

[0090] figure 1 A processing plant 1 according to the invention is shown. The processing facility comprises conventional shipping cargo containers 2 . In the shipping container 2 there is a guide rail 3 on which a drivable support device 4 ( image 3 ). On this support device 4 are arranged three mutually independent plank tables 5 , 6 , 7 . Furthermore, rollers 8 are provided on the support device 4 .

[0091] exist figure 1 In , the processing equipment 1 is not yet in use. The panel workbenches 5, 6, and 7 are folded so that they can be supported in the shipping container 2 smoothly. Board lengths of up to 40 m and board widths of up to 5 m can be transported in the freight container 2 . In this embodiment, the length is about 40 feet and the width is about 3 meters.

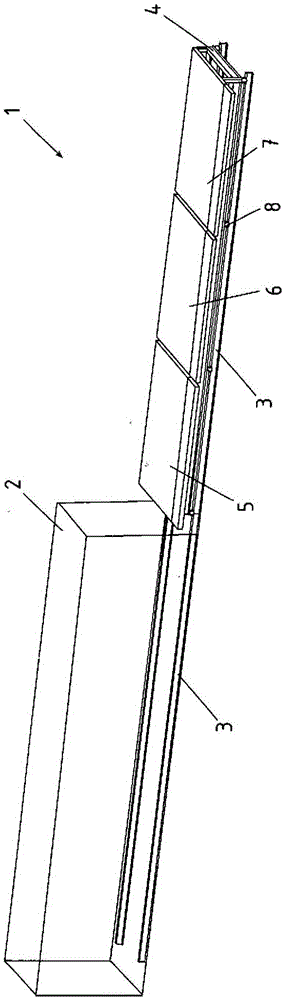

[0092] figure 2 shows a 3 with extended rail figure 1 The processing equipment 1 of the present invention has a support device 4 with a panel table 5, 6, 7 supported on the guide rail in the form o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com