Method for transplanting flue-cured tobacco in upland field

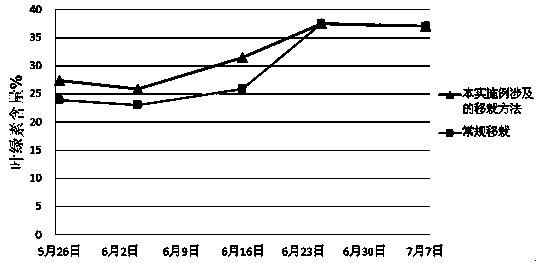

A flue-cured tobacco and mountain technology, which is applied in the fields of botanical equipment and methods, horticulture, and application, can solve the problems of complicated operation, high cost, and large labor in the transplanting method of flue-cured tobacco seedlings, so as to improve the efficiency and survival rate, and reduce the migration rate. The effect of planting cost and improving survival rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

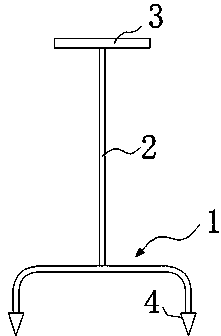

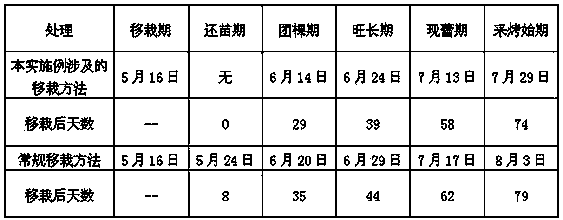

[0025] Specific embodiment: a method for transplanting flue-cured tobacco in mountainous areas, the key points of which are to comb the land before planting to form a ridge and cover the ridge with a film seal; Throw the small tobacco seedlings of the first day into the hole and place them under the hole; after throwing the seedlings, use water mixed with the seedling fertilizer to apply the root-fixing water, spray the insecticide liquid agent at the same time, and then throw the insecticide granules into the small hole; After the top leaves of the seedlings grow small holes, the seedling fertilizer is applied by punching fertilization holes at the edge of the tobacco seedlings, and topdressing is carried out when the tobacco seedlings enter the group stage.

[0026] More specifically, the above method includes the following steps during implementation:

[0027] a. Before transplanting, comb the transplanted land to form a ridge body, which faces east and west, with a height of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com