Large-sized composite net enclosure

A large-scale, net-enclosed technology, applied in fish farming, application, climate change adaptation, etc., can solve the problems of short service life, many fish escape accidents, and poor anti-ultraviolet aging ability, so as to improve the service life and equipment. Level, improve strength and anti-wind and wave performance, the effect of anti-wind and wave current effect is obvious

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

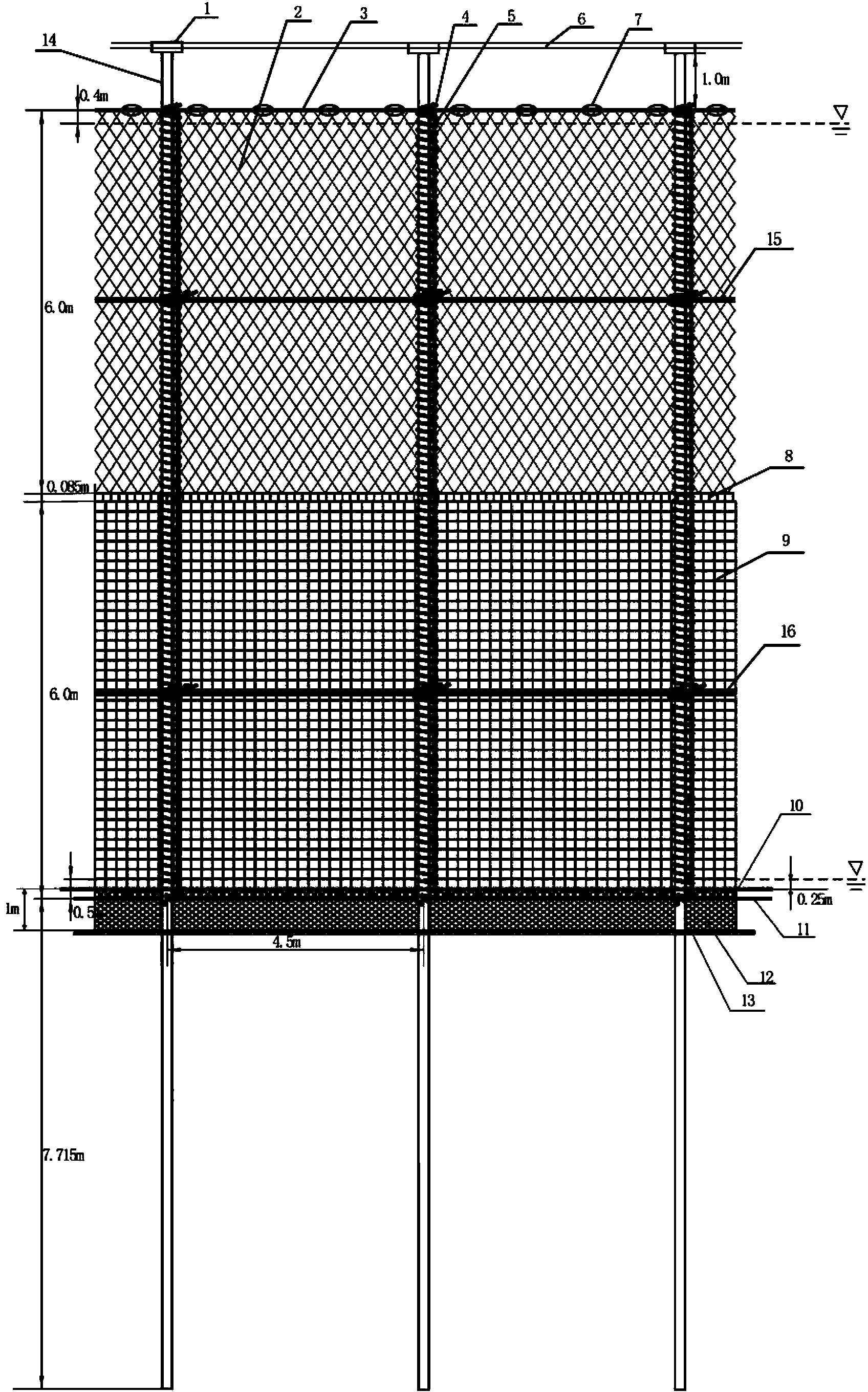

[0007] The best way to implement the present invention is illustrated below in conjunction with the accompanying drawings:

[0008] The technical scheme of the present invention consists of reinforced concrete pile 14, channel steel 6, copper alloy braided net, three-strand polyester rope, ultra-high molecular weight polyethylene fiber, ultra-high molecular weight polyethylene warp-knitted net, polypropylene rope, core-through float 7, stainless steel tube, high-density polyethylene sheet, lead core braided rope 13 and waste net clothes, the reinforced concrete pile is a cylindrical tube, with an outer diameter of 40cm, a wall thickness of 9.5cm, and a length of 20.8m. The outer wall of the pile is coated with 5 layers of environmentally friendly marine anti-corrosion After the dirty paint is dried, a pier 1 is poured on the top of the pile. The inner diameter of the pier is 21cm, the outer diameter is 120cm, and the height is 40cm. The reinforced concrete pile is poured on lan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com