Environment friendly rush sandal and manufacture methods thereof

A production method and an environment-friendly technology, which is applied to shoe uppers, footwear, boot legs, etc., to achieve the effects of low cost, comfortable wearing, and easy popularization and application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

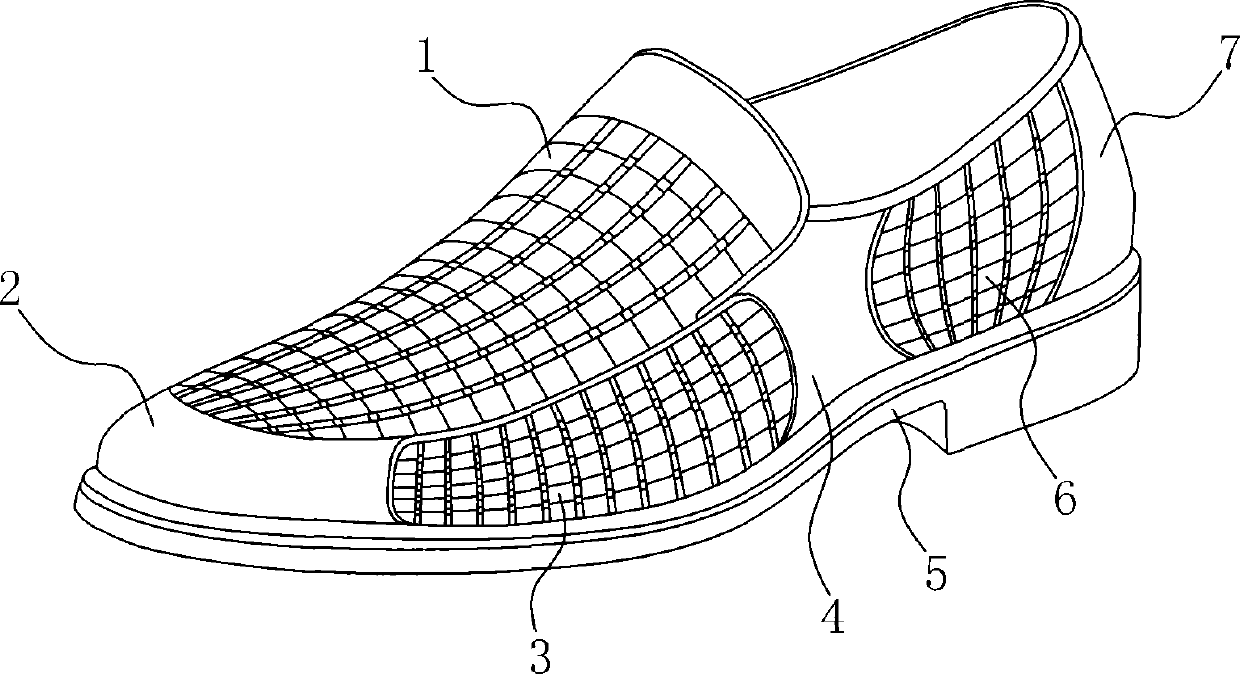

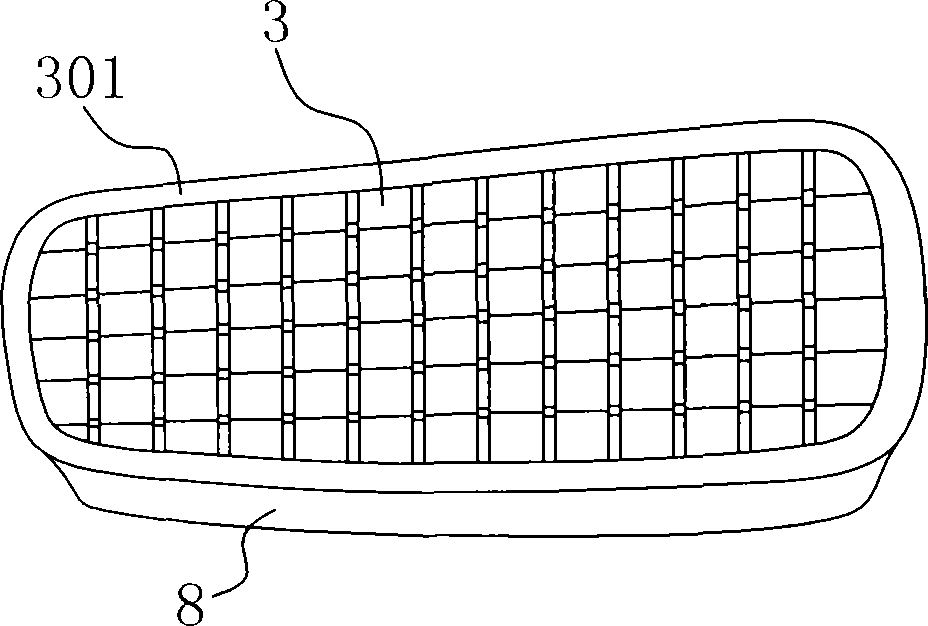

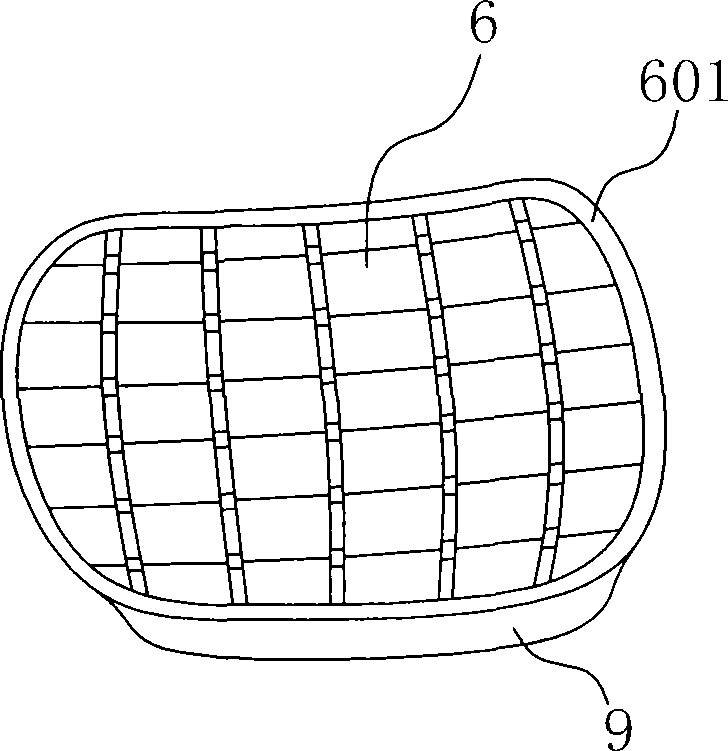

[0028] Figure 1-10 Name and serial number: upper 1, front upper 2, front side upper 3, first hemming layer 301, middle side upper 4, sole 5, rear side upper 6, second hemming layer 601, rear upper 7, second hemming layer One embedded strip 8, the second embedded strip 9, insole 10, extension section 11, insole hemming layer 12, rush 13, rush extension section 1301, machine stitching thread 1302, lining 1303, support frame 14, limit block 15 , 16 rivets.

[0029] Now in conjunction with the accompanying drawings, the specific implementation will be described as follows taking the manufacturing method as an example.

[0030]Environmentally friendly rush sandal structure, including upper 1, front upper 2, side upper, rear upper 7, sole, side upper is divided into front side upper 3, middle side upper 4, rear side upper 6, and the two ends of the middle side upper are respectively It is connected with one end of the front side panel 3 and the rear side panel 6, and the other en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com