Sewage suction device for filter for agricultural irrigation

An agricultural irrigation and filter technology, which is applied in the field of agricultural irrigation, can solve the problems such as the inability of fouling to be sucked into the sewage pipe, separation, and the influence of the suction effect of the suction nozzle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

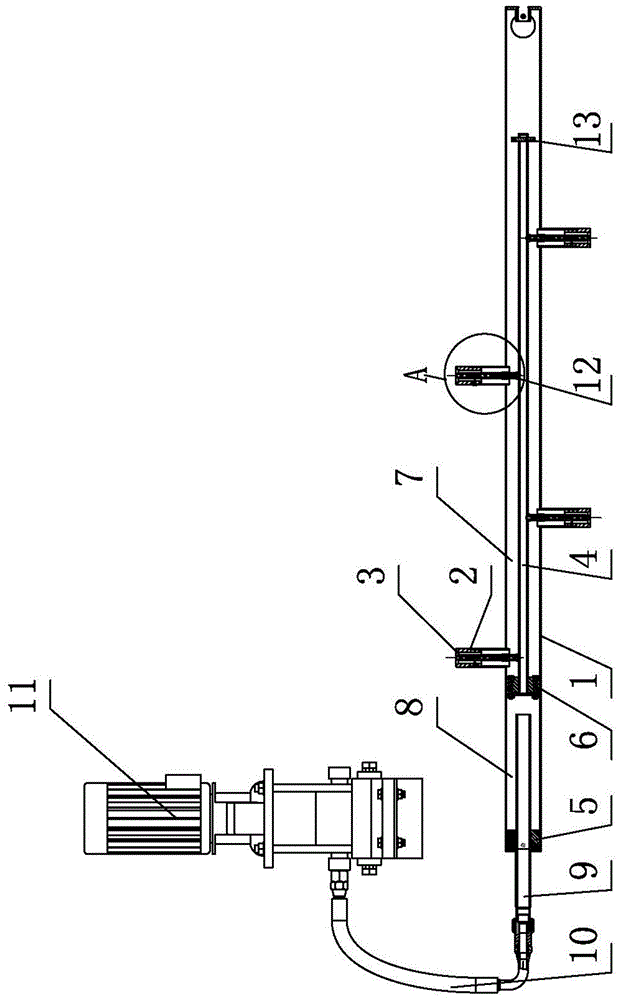

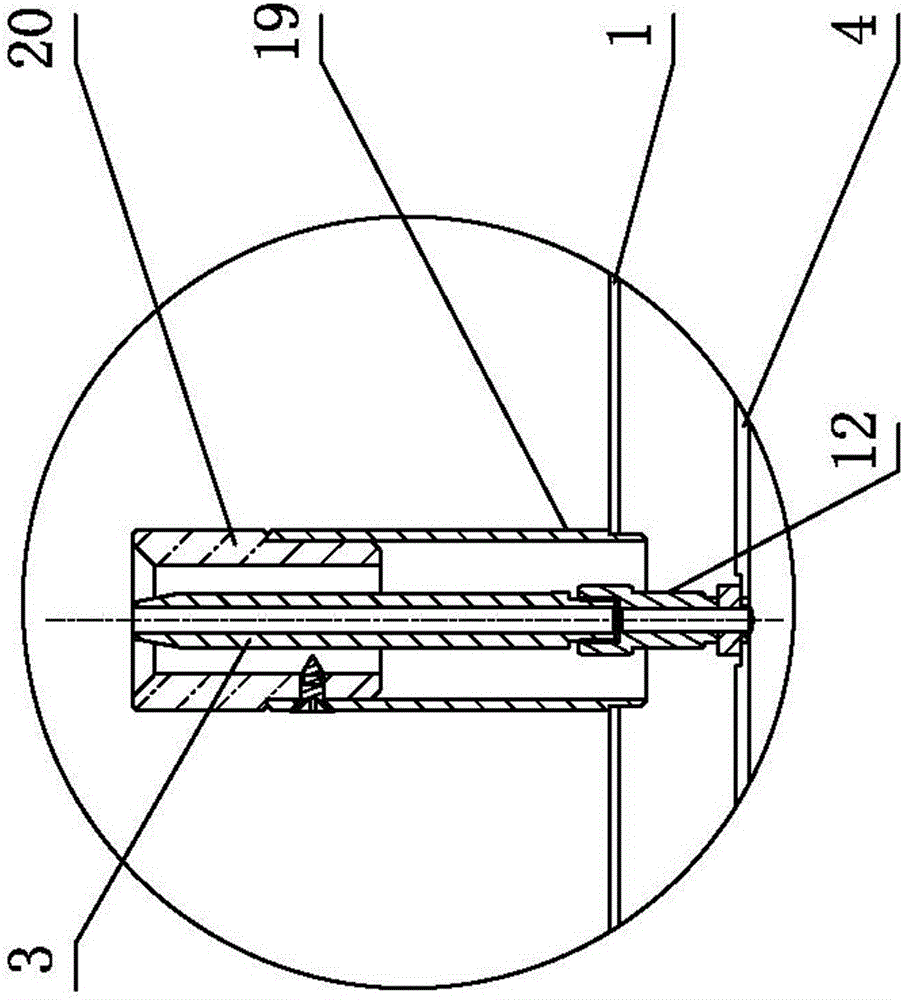

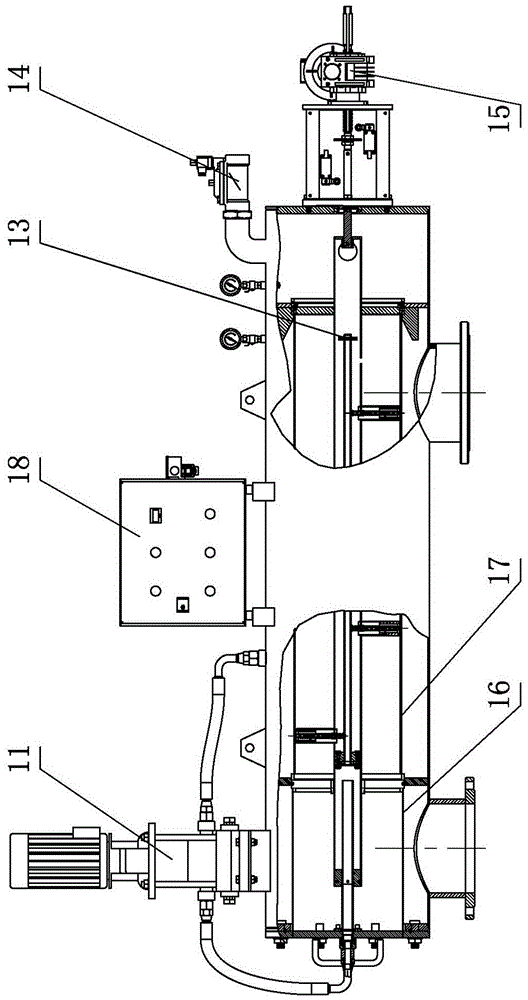

[0019] Such as figure 1 , figure 2 As shown, the sewage suction device of a filter for agricultural irrigation according to the embodiment of the present invention mainly includes a sewage suction pipe 1 and a plurality of high-pressure suction nozzles 2, and a plurality of high-pressure suction nozzles 2 are uniformly fixed on the bottom of the sewage suction pipe 1 The outer wall communicates with the sewage suction pipe 1, and a plurality of high-pressure suction nozzles 2 are provided with high-pressure nozzles 3, which can spray high-pressure water flow.

[0020] The high-pressure nozzle 3 is concentric with the high-pressure suction nozzle 2, and a high-pressure pipe 4 concentric with the sewage suction pipe 1 is arranged inside the sewage suction pipe 1. The high-pressure water flow is obtained in the middle, and the high-pressure suction nozzle 3 sucks at the moment when the scale is washed away by the high-pressure nozzle 3 .

[0021] In a preferred embodiment, an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com