Pt/silicon nanometer array structure composite material and preparation method thereof

A technology of silicon nano-array and composite material, applied in the field of Pt/silicon nano-array structure composite material and its preparation, can solve problems such as unfavorable photoelectric energy conversion, increase in surface defects, secondary chemical damage, etc., and achieve good visible light absorption ability, Reduced recombination centers, effective absorption and transformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

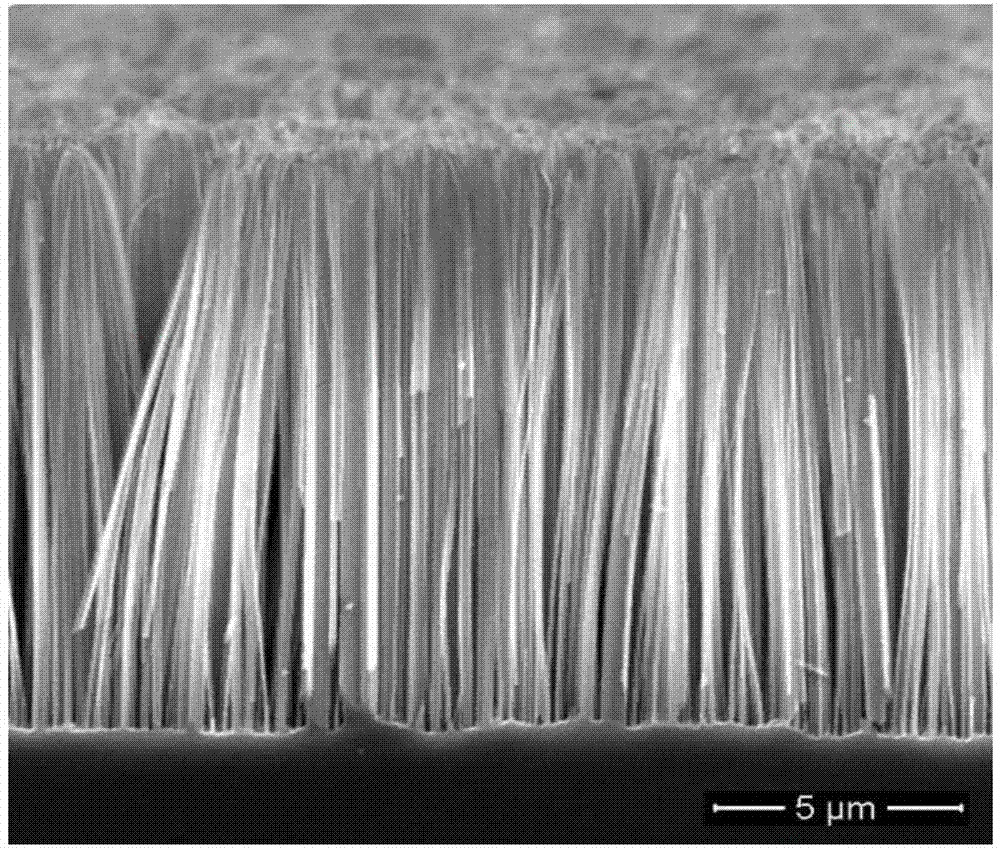

[0042] 1. Preparation of silicon nanowire arrays:

[0043] Cut the p-type Si wafer into 1 × 2 cm 2 The squares were ultrasonically washed with deionized water, absolute ethanol and acetone, and then immersed in H 2 SO 4 and H 2 o 2 Take out after 10 minutes in the mixed solution (mixed solution by H 2 SO 4 (98%) and H 2 o 2 (35%) configured according to the volume ratio of 3:1). The silicon wafer was placed in a 5% HF aqueous solution, allowed to stand for 1 minute, and then taken out. The silicon wafer was quickly transferred to a solution containing 4.8M HF and 5mM AgNO 3 In the mixed solution, stir slowly, and take it out after 60 seconds of reaction. Then transfer the silicon wafer to 4.8M HF and 0.25mM H 2 o 2 In the solution, react for 45 minutes under the condition of avoiding light, and obtain the silicon nanowire array. Next, the silicon nanowire arrays were transferred into nitric acid solution (V HNO3(63%) :V 水 =1:1) for 3 hours, remove Ag ions, and t...

Embodiment 2

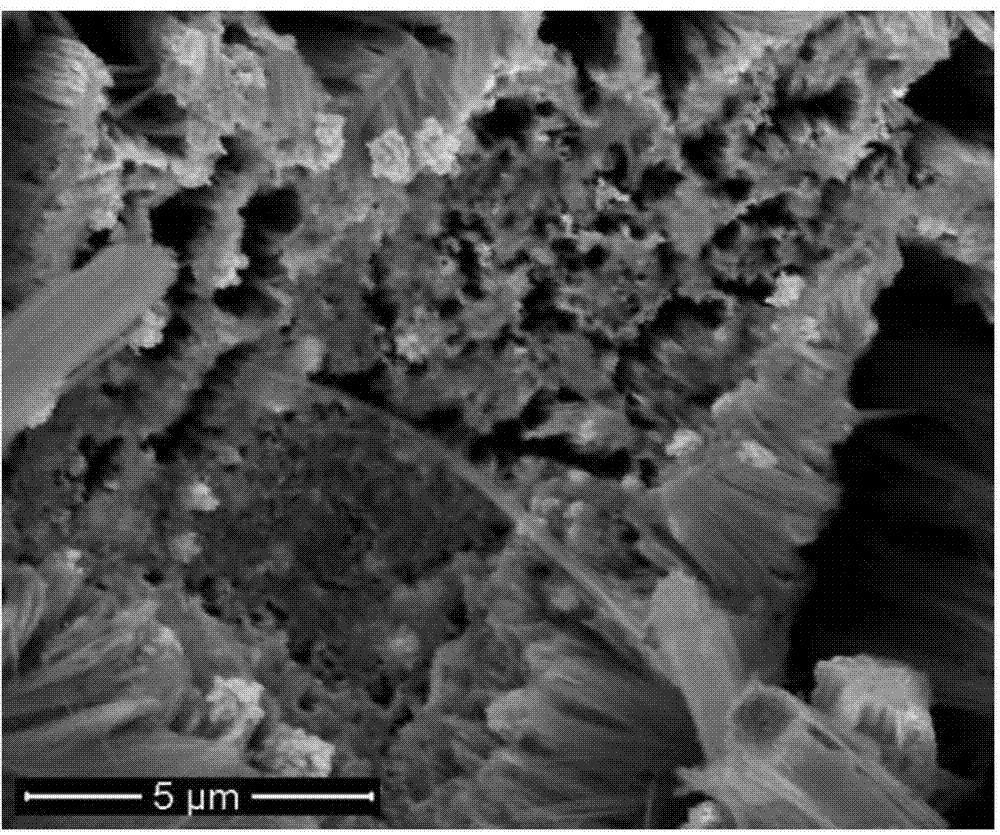

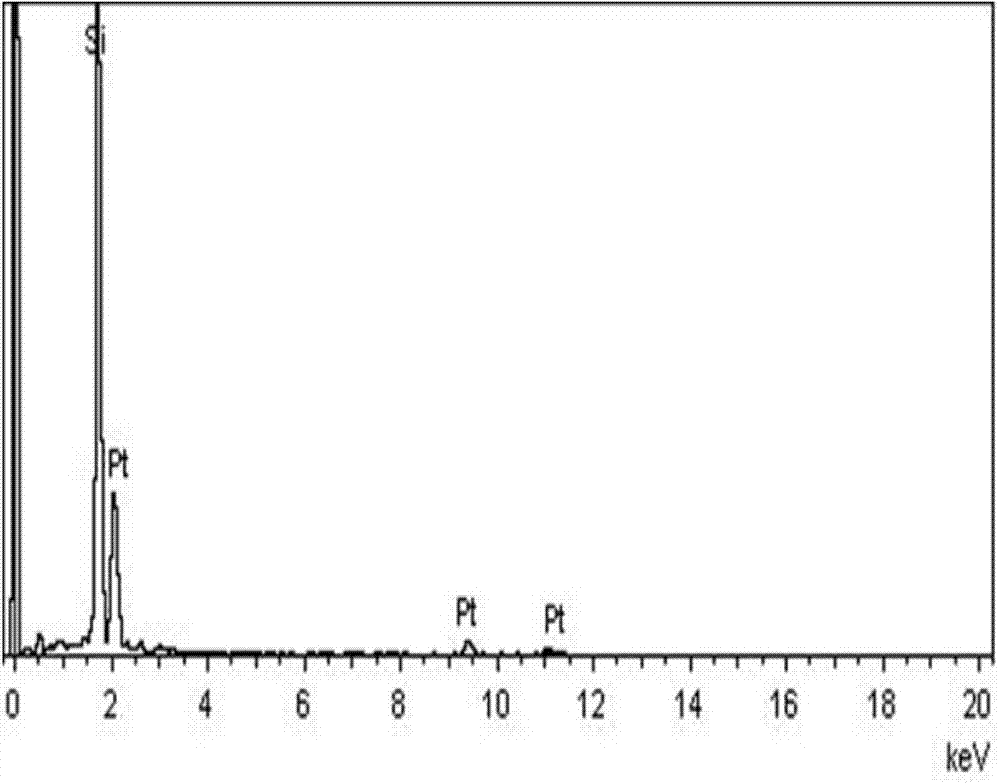

[0048] 1. Preparation of porous silicon nanoarray structure:

[0049] Cut the p-type Si wafer into 1 × 2 cm 2 The squares were ultrasonically washed with deionized water, absolute ethanol and acetone, and then immersed in H 2 SO 4 and H 2 o 2 Take out after 10 minutes in the mixed solution (mixed solution by H 2 SO 4 (98%) and H 2 o 2 (35%) configured according to the volume ratio of 3:1). The silicon wafer was placed in a 5% HF aqueous solution, allowed to stand for 1 minute, and then taken out. The silicon wafer was rapidly transferred to a solution containing 4.8M HF and 5mM AgNO 3 In the mixed solution, stir slowly, and take it out after 60 seconds of reaction. Then transfer the silicon wafer to 4.8M HF and 0.25mM H 2 o 2 In the solution, react for 10 minutes under the condition of avoiding light, and obtain the porous silicon nano-array. Next, the porous silicon nanoarrays were transferred into nitric acid solution (V HNO3(63%) :V 水 =1:1) for 3 hours, remov...

Embodiment 3

[0053] 1. Preparation of silicon nanowire arrays:

[0054] Cut the n-type Si wafer into 1 × 2 cm 2 The squares were ultrasonically washed with deionized water, absolute ethanol and acetone, and then immersed in H 2 SO 4 and H 2 o 2 Take out after 10 minutes in the mixed solution (mixed solution by H 2 SO 4 (98%) and H 2 o 2 (35%) configured according to the volume ratio of 3:1). The silicon wafer was placed in a 5% HF aqueous solution, allowed to stand for 1 minute, and then taken out. The silicon wafer was quickly transferred to a solution containing 4.8M HF and 5mM AgNO 3 In the mixed solution, stir slowly, and take it out after 60 seconds of reaction. Then transfer the silicon wafer to 4.8M HF and 0.25mM H 2 o 2 In the solution, react for 45 minutes under the condition of avoiding light, and obtain the silicon nanowire array. Next, the silicon nanowire arrays were transferred into nitric acid solution (V HNO3(63%) :V 水 =1:1) for 3 hours, remove Ag ions, and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com