Spraying gun support frame and spraying gun assembly

A spray gun and bracket technology, which is applied to spray devices, coatings, devices for coating liquid on surfaces, etc., can solve problems such as being unable to stand directly on the table, spraying bubbles, and paint shaking, and to increase the balance torque, Space-saving and stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, further describe the technical solution of the present invention, but the present invention is not limited to these embodiments.

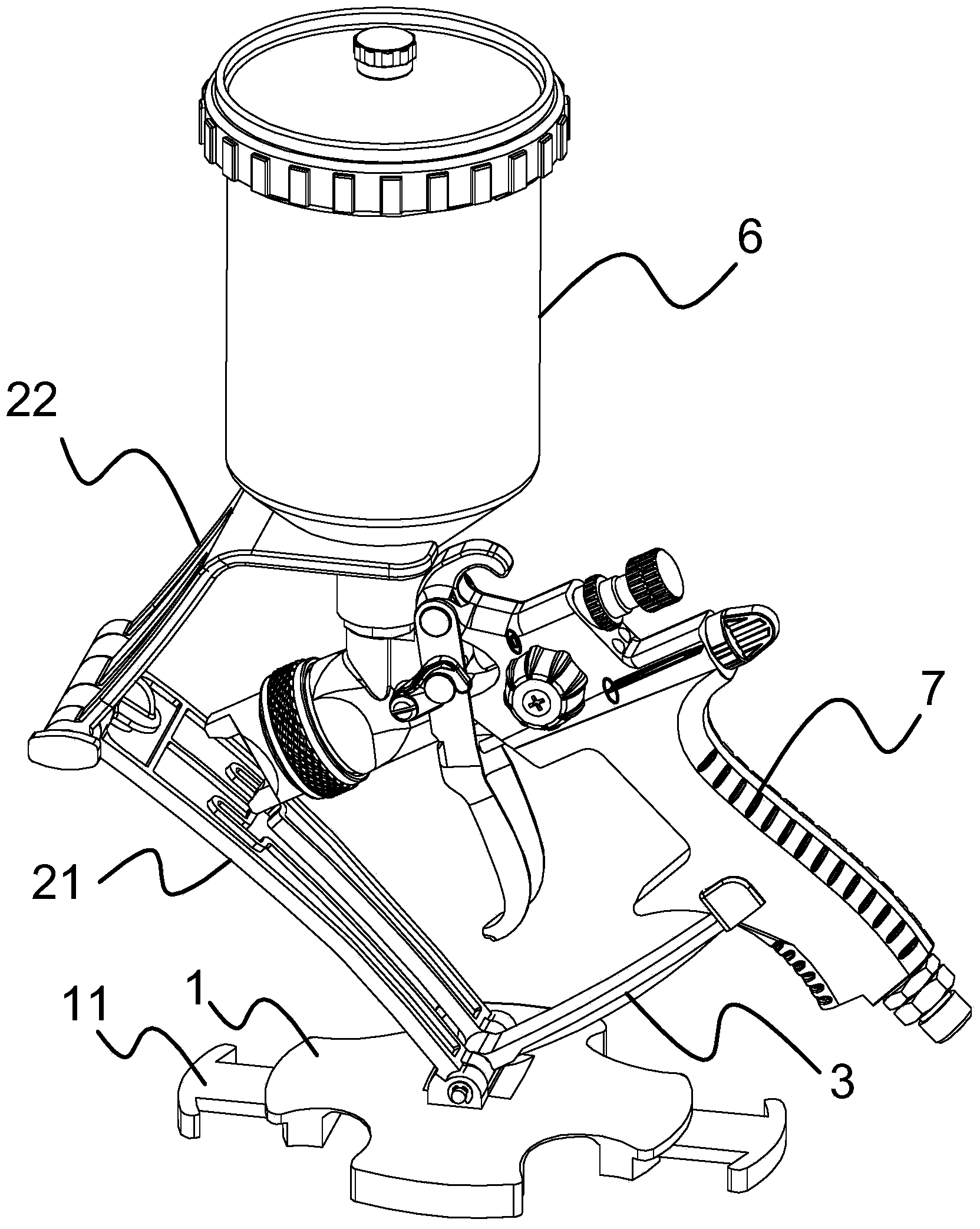

[0027] The invention relates to a spray gun support frame, which is used to support and fix a spray gun, and is especially suitable for occasions where the spray gun is supported in order to prevent the spray gun from being inverted when it is not in use, such as exhibitions, spraying operation intervals, and the like.

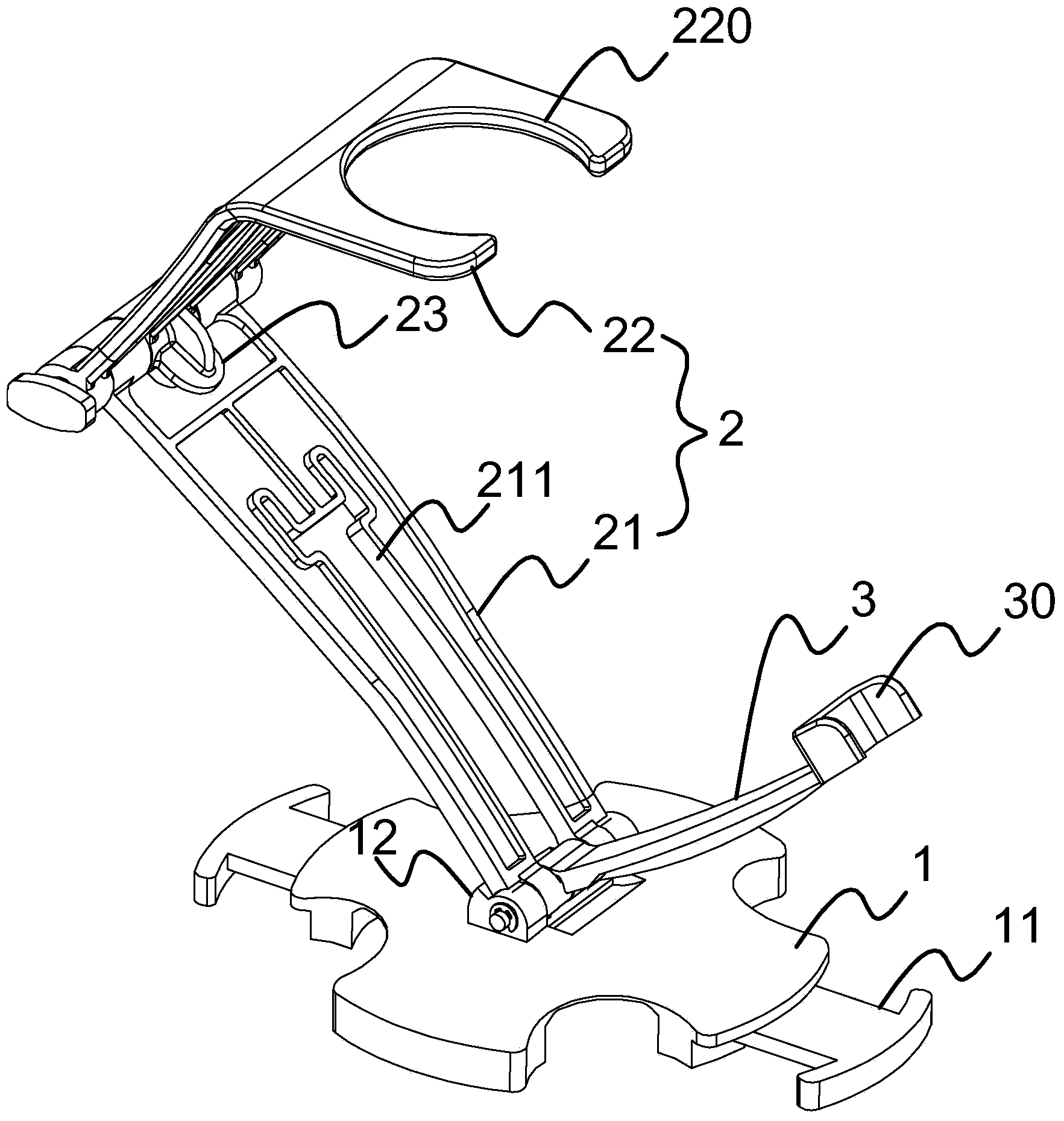

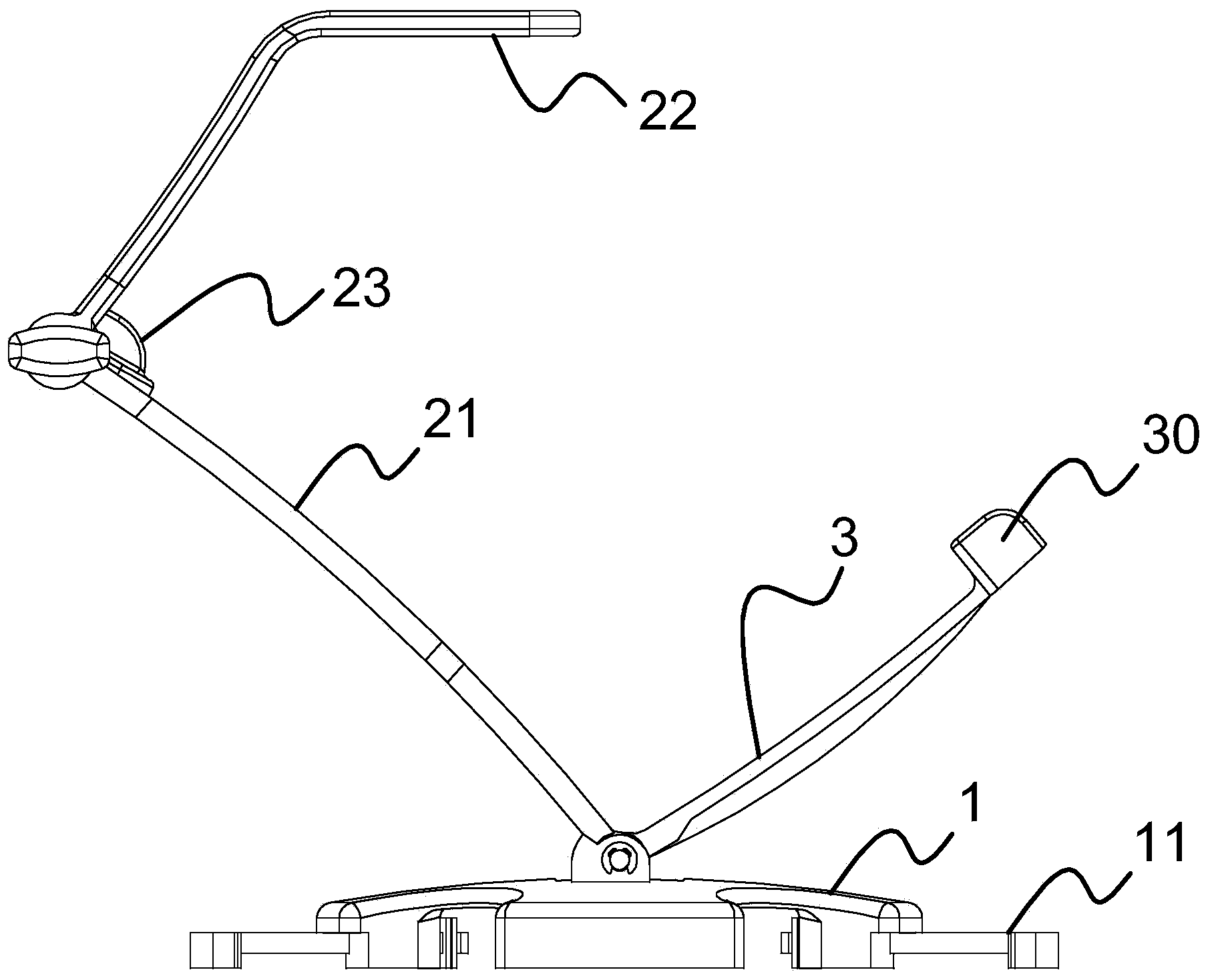

[0028] The structure of the spray gun support frame is as follows: figure 1 , figure 2 As shown, it includes a chassis 1 , a first bracket 2 and a second bracket 3 . Wherein, the chassis 1 has a certain size of width and area, and provides sufficient supporting moment to prevent the spray gun from turning over. In this embodiment, the chassis 1 is approximately cross-shaped, and of course it can also be disc-s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com