Machining method for gear shaft in angle steering gear assembly

A processing method and technology for an angular steering gear, which are applied in the processing field of gear shafts, can solve problems such as low service life, cracking, loose gear shaft snap rings, etc., meet the requirements of fatigue resistance and torsional strength, improve stability, prolong effect of cycles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

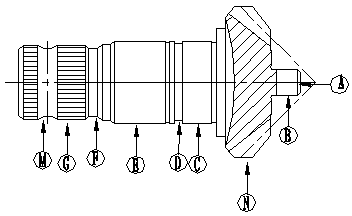

[0019] A method for processing a gear shaft in an angle steering assembly, characterized in that:

[0020] Its processing steps are as follows:

[0021] 1). Choose 20CrMnTi material, the diameter is 55-60mm, the length is 120mm, and the material is broken;

[0022] 2). Clamp one end, car the other end face A, and drill the center hole on the end face A;

[0023] 3). According to the requirements of the design drawings, rough turn the outer circle at N, C, D, E, F, G, rough turn the size of the outer circle from B to N, control the length of each section, and leave a machining allowance of 2 for the outer circle after rough turning -3mm, phosphorus saponification lubrication treatment is carried out during processing;

[0024] 4). Spline milling at G, straight grain 79 teeth, modulus 0.32mm;

[0025] 5). According to the requirements of the design drawings, use a forming knife to process the radius R of 5.2mm at M;

[0026] 6). According to the requirements of the design dr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com