A super-high pressure working cylinder structure of a warm isostatic press

A technology of warm isostatic press and working cylinder, which is applied in the direction of press and manufacturing tools, can solve the problems such as the increase of the surface temperature of the working cylinder, the decrease of the temperature of the working cylinder, the influence of the surrounding devices, etc., so as to reduce the processing cost and facilitate the operation. , The effect of reducing the cost of finished products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

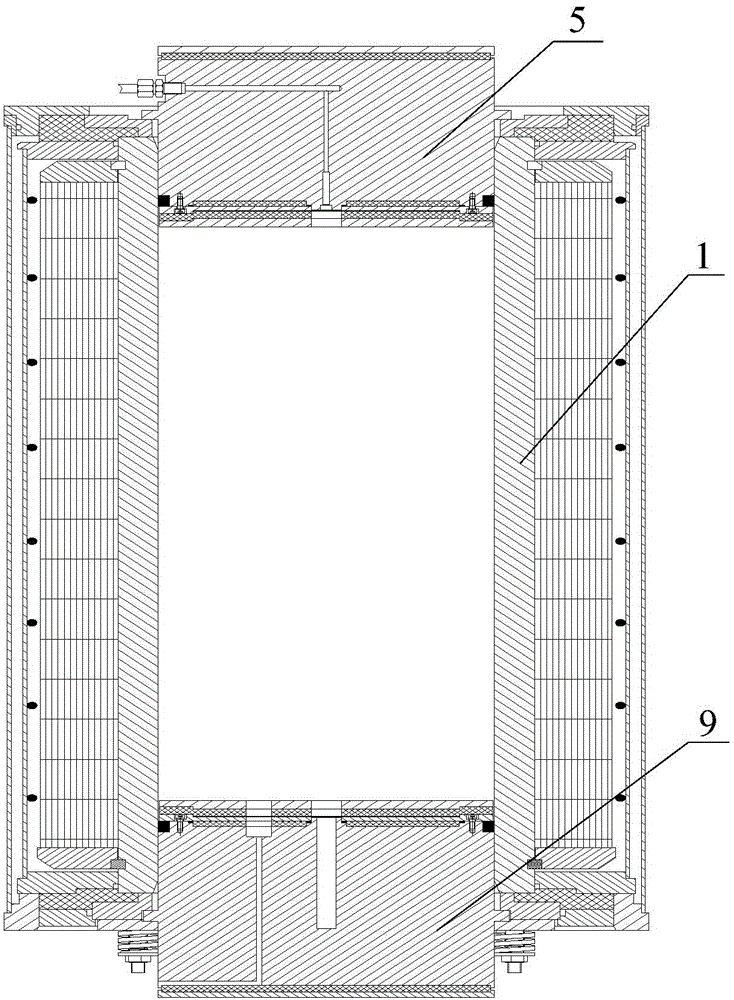

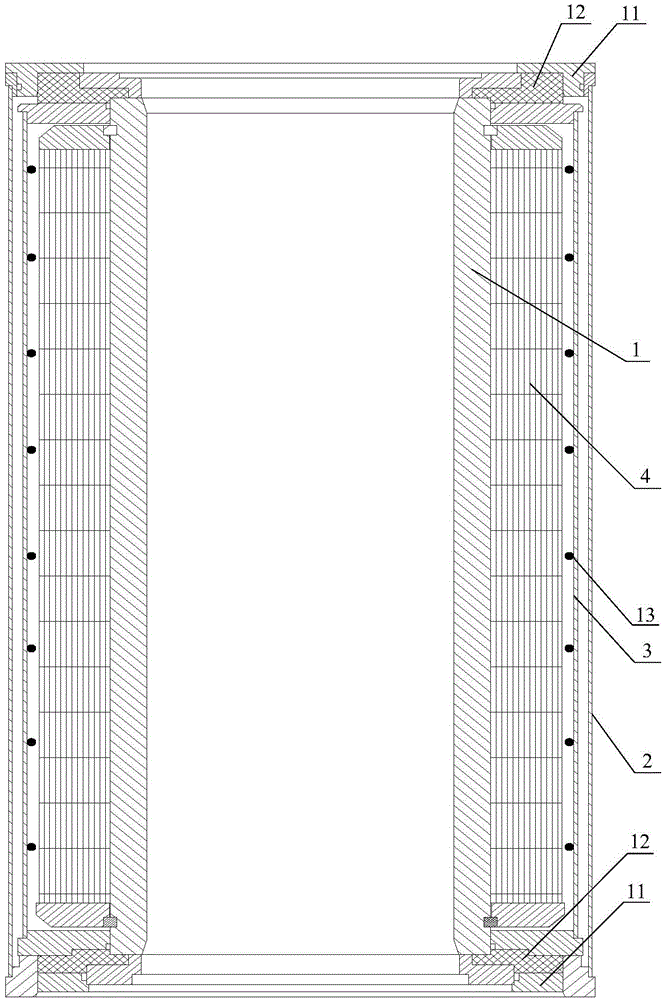

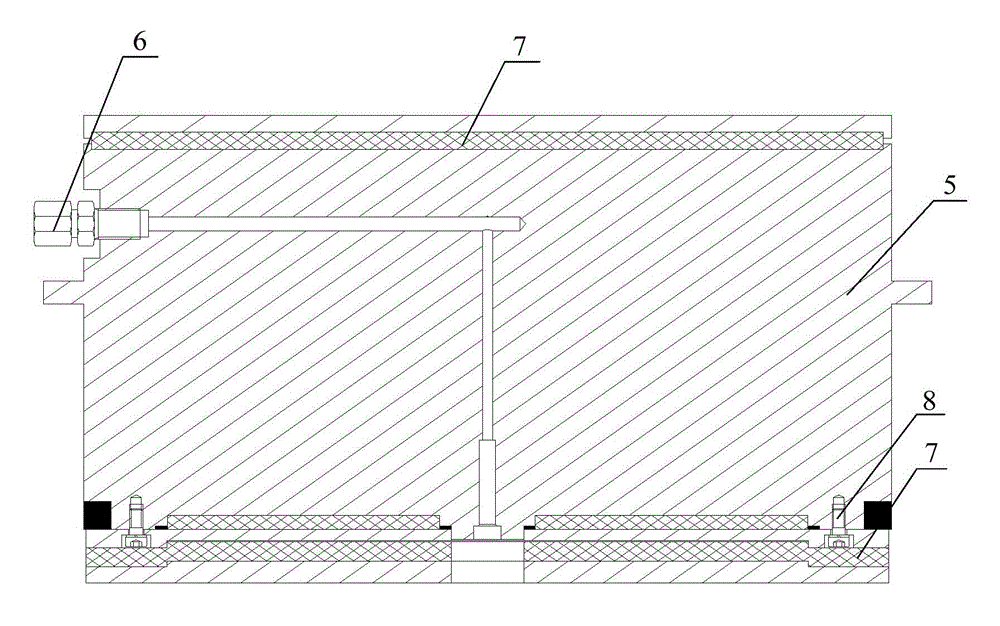

[0032] Such as Figure 1~4 As shown, the ultra-high pressure working cylinder structure of the warm isostatic press of the present invention is mainly composed of a working cylinder body, and the working cylinder body includes a core barrel 1, such as figure 2 shown. The core barrel 1 is a cylindrical tubular structure, that is, the core barrel 1 has a cylindrical cavity inside, and the cavity runs through the upper and lower surfaces of the core barrel 1 . In order to make the core barrel 1 of the present invention have certain strength and temperature resistance, so that it can withstand and transmit radial pressure during operation, the core barrel of the present invention is made of high-strength alloy steel.

[0033] In order to further improve the strength of the working cylinder of the present invention, a reinforcing layer 4 is also provided on the core tube 1, such as figure 2 shown. The reinforcing layer 4 of the present invention is made of steel wire, and is s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com