Drilling winch

A winch and drilling technology, applied in the direction of hoisting device, clockwork mechanism, etc., can solve the problems of easy fracture of welds, casualties, shutdown of the whole mine, etc., and achieve the effects of not easy to fracture, cost saving, and improving service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

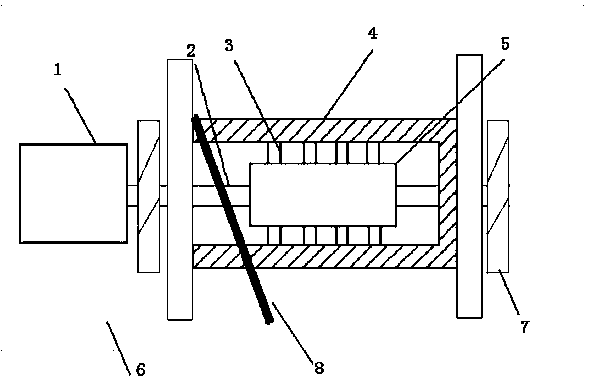

[0025] Such as figure 1 As shown, the drawworks for drilling includes a driving motor 1, an output shaft 2, a connecting arm 3, a reel 4, an inner rotating shaft 5 and a steel cable 8, one end of the output shaft 2 is connected to the power output end of the driving motor 1, and the inner rotating shaft 5 Sleeved on the output shaft 2, the connecting arm 3 evenly and vertically passes through the axis of the inner rotating shaft 5, the inner wall of the sleeve 4 is connected with the connecting arm 3, and the steel cable 8 is fixed on the reel 4. The driving motor 1 drives the reel 4 to rotate through rotation, and the reel 4 releases or recovers the steel cable 8, thereby realizing the hoisting effect of the winch.

Embodiment 2

[0027] Such as figure 1 As shown, the above-mentioned connecting arms 3 are multiple and all pass through the axis of the inner rotating shaft 5, and are connected to the inner wall of the reel. Setting a plurality of connecting arms 3 can share the force applied to the reel 4 as much as possible. With a small force, the winch is not easy to break between the motor and the reel under heavy load, which improves the service life of the winch and saves costs.

Embodiment 3

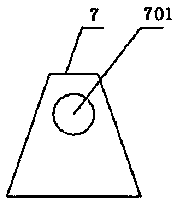

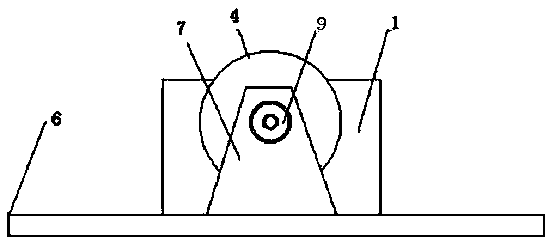

[0029] Such as figure 1 with figure 2 As shown, on the basis of Embodiment 1, this embodiment also includes a base 6 and two fixing seats 7, the drive motor 1 is fixed on the base 6, and the two fixing seats 7 are relatively arranged on the base 6, and the Both ends of the reel 4 are rotatably fixed on the fixed seat 7 , and there is a gap between the reel 4 and the base 6 . The reel 4 rotates on the fixed seat 6 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com